Bridge support with height capable of being repeatedly adjusted and operation method thereof

A technology of bridge bearings and bearings, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as unsatisfactory, uneven subsidence, endangering driving safety, etc., and achieve accurate and stable elevation adjustment values, uniform heat transfer, The effect of convenient heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

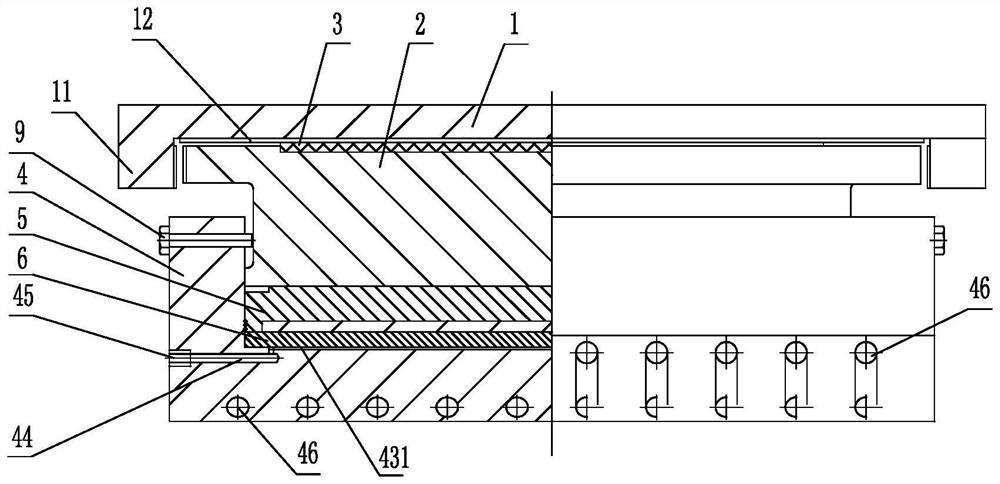

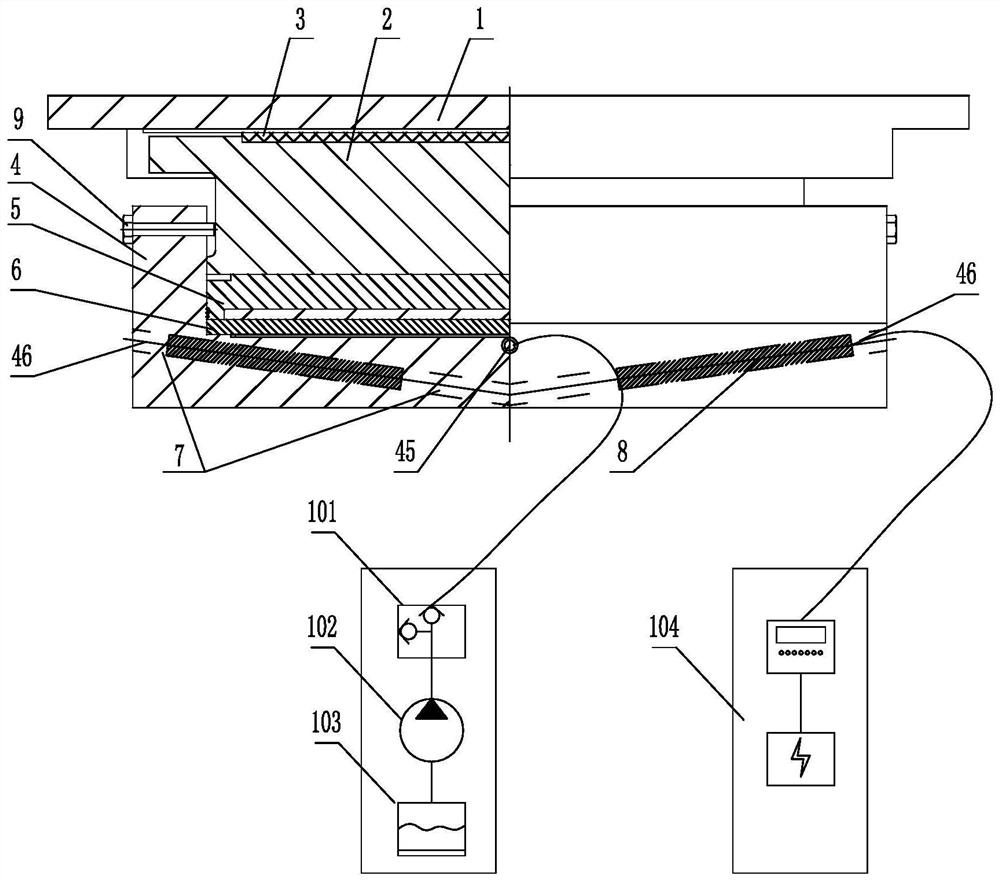

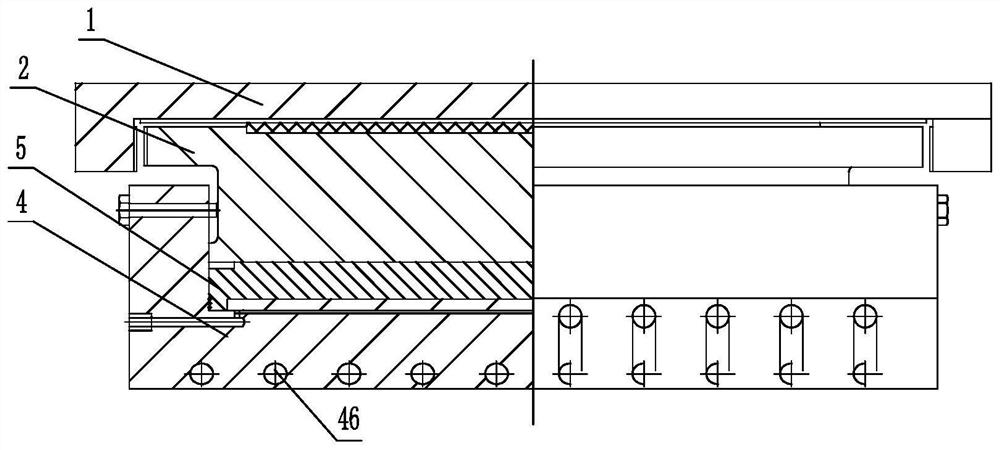

[0068] A bridge support that can be repeatedly adjusted in height, including a support top plate 1, a support bottom plate 4, and a steel liner 2 installed between the support top plate and the support bottom plate, the steel liner supports the support top plate, The bottom of the steel liner falls in the circular pelvis 41 of the base plate 4; the circular pelvis 41 at the bottom of the steel liner 2 is provided with a jacking mechanism, including a jacking assembly, a filling system and a heating system, installed in The jacking assembly in the circular pelvis includes a sealing member 5 and a fusible alloy plate 6, the sealing member 5 supporting the steel liner is in interference fit with the circular pelvic wall, and the fusible alloy plate at the bottom of the sealing member is seated on the support The bottom surface of the circular pelvic cavity 41 of the bottom plate is matched with the circular pelvic cavity wall clearance;

[0069] The filling system is arranged on ...

Embodiment 2

[0077] An operation method of a bridge support that can be repeatedly adjusted in height is an operation method of a bridge support that can be repeatedly adjusted in height described in the above-mentioned embodiments, including an operation method of raising the height of the support and an operation method of lowering the height of the support , the specific steps are:

[0078] The operation method of the elevation raising of the S1 support includes the following steps:

[0079] S11 installs the limit bolt 9;

[0080] S12 installs the external valve group to the valve interface 45 of the support, and confirms that each valve remains closed;

[0081] S13 connects the high-pressure filling system, connects the pump material pipe of the high-pressure filling system to the temperature-controlled material tank, and the delivery pipeline of the temperature-controlled material tank is connected to the valve port of the valve group;

[0082] S14 heats the temperature-controlled m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com