Height-adjusting force measuring bearing

A technology of force measurement and height adjustment, which is applied to bridge parts, bridges, buildings, etc., can solve the problem of inability to verify the rationality of bridge design theory, reliability design method, unfavorable timely monitoring and evaluation of bridge structural health, and inability to detect bearings The vertical bearing capacity of the support under the force situation and other issues, to achieve the effect of simple and reliable force measurement and height adjustment method, compact structure and good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

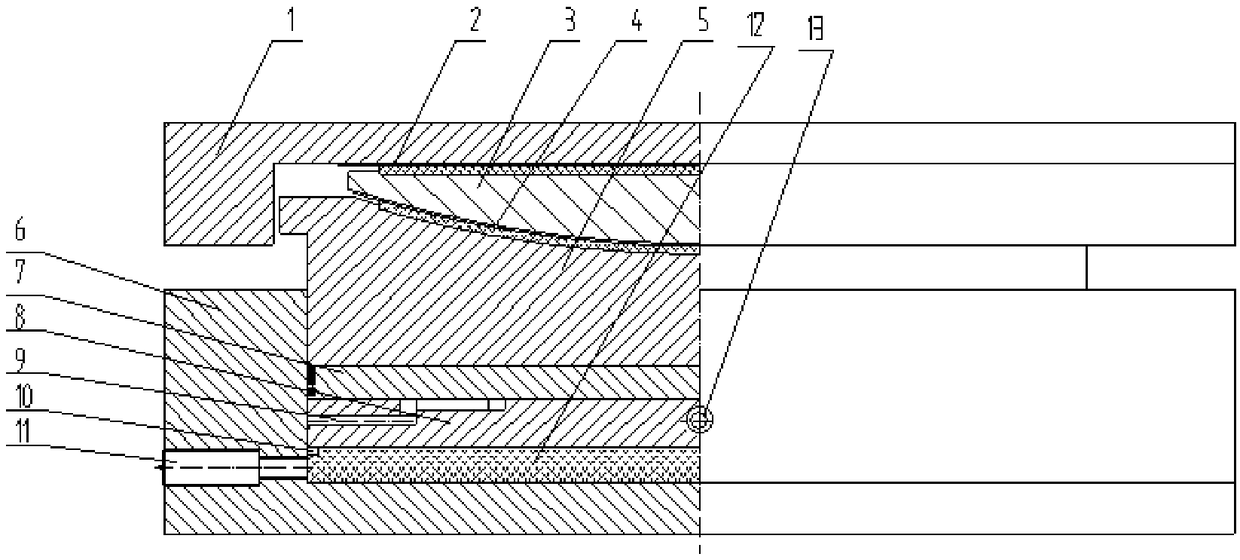

[0020] Such as figure 1 As shown, a height-adjusting force-measuring support includes a top plate 1, a flat wear-resistant plate 2, a spherical crown lining plate 3, a spherical wear-resistant plate 4, a sliding seat 5, a base 6, a sealing plate 7, a filling pad 8, Filling pipe 9 , sealing ferrule 10 , fiber grating load cell 11 , load cell elastic body 12 and quick connector 13 .

[0021] The bottom surface of the top plate 1 is welded with a mirror stainless steel slide plate, and the top plate 1 and the plane wear-resistant slide plate 2 form a plane sliding friction pair, and the plane wear-resistant slide plate 2 is fastened and embedded in the spherical crown lining plate 3 through adhesive bonding and screw or anchoring In the groove, the surface of the convex ball of the spherical crown liner 3 can be treated with a coated stainless steel plate or electroplate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com