Revolving fixing and clamping device capable of improving processing accuracy

A clamping device and processing accuracy technology, which is applied to positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of difficulty in ensuring the processing accuracy of workpieces, increasing the workload of staff, and increasing the error of clamping, etc., to achieve The effect of reducing the number of clamping times, ensuring the processing quality, and increasing the qualified rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

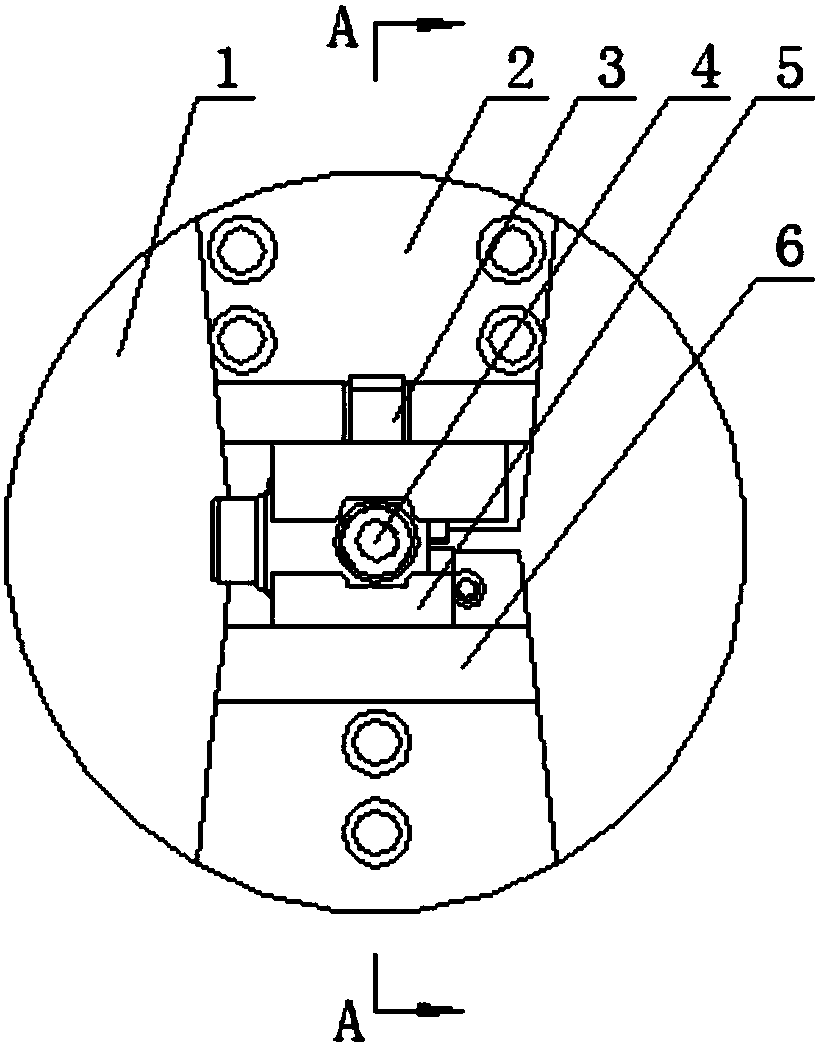

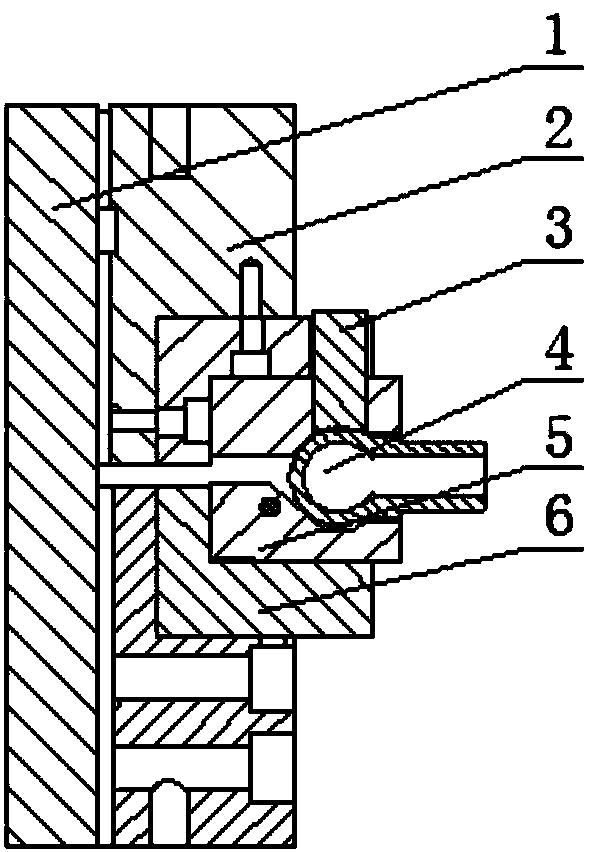

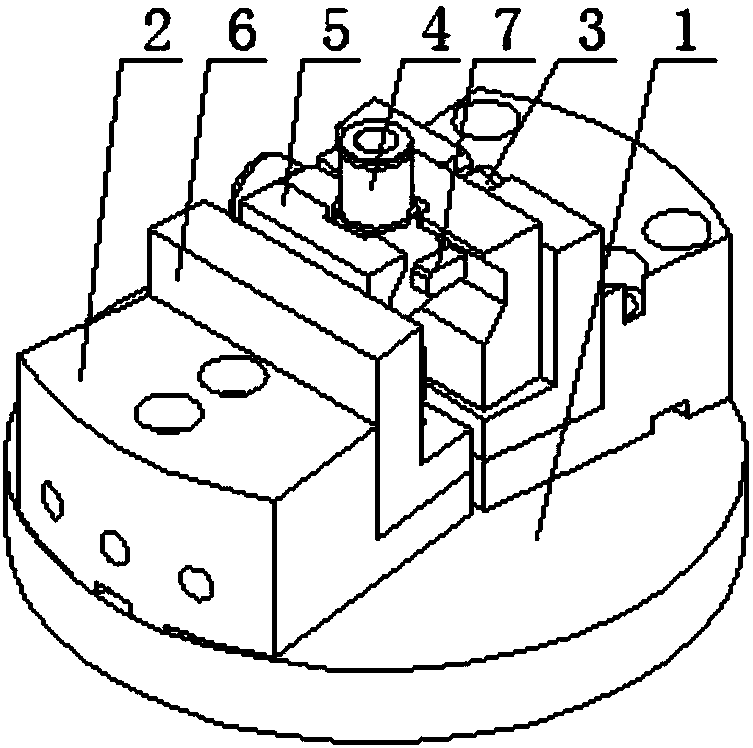

[0019] A rotary fixed chucking device capable of improving machining accuracy, comprising a two-jaw chuck 1, a positioning block 2 and a quick-change lock 5, the two-jaw chuck has two claws, and each claw is connected with a positioning block, the inner sidewall of each positioning block is all connected with an L-shaped mounting plate 6, these two L-shaped mounting plates are arranged oppositely, and a quick-change lockset is installed inside it.

[0020] This quick change lockset is made of base 9 and loam cake 8, and loam cake is fastened on the base, and one end of loam cake is hinged with base, and the inner side wall of loam cake and base all makes workpiece positioning groove, and workpiece locating groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com