Equipment for positioning and mounting corner support

A technology of positioning installation and corner rotation, which is applied in welding equipment, auxiliary welding equipment, metal processing equipment, etc., and can solve problems such as heavy weight, time-consuming and labor-intensive products, and difficulty in guaranteeing product processing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

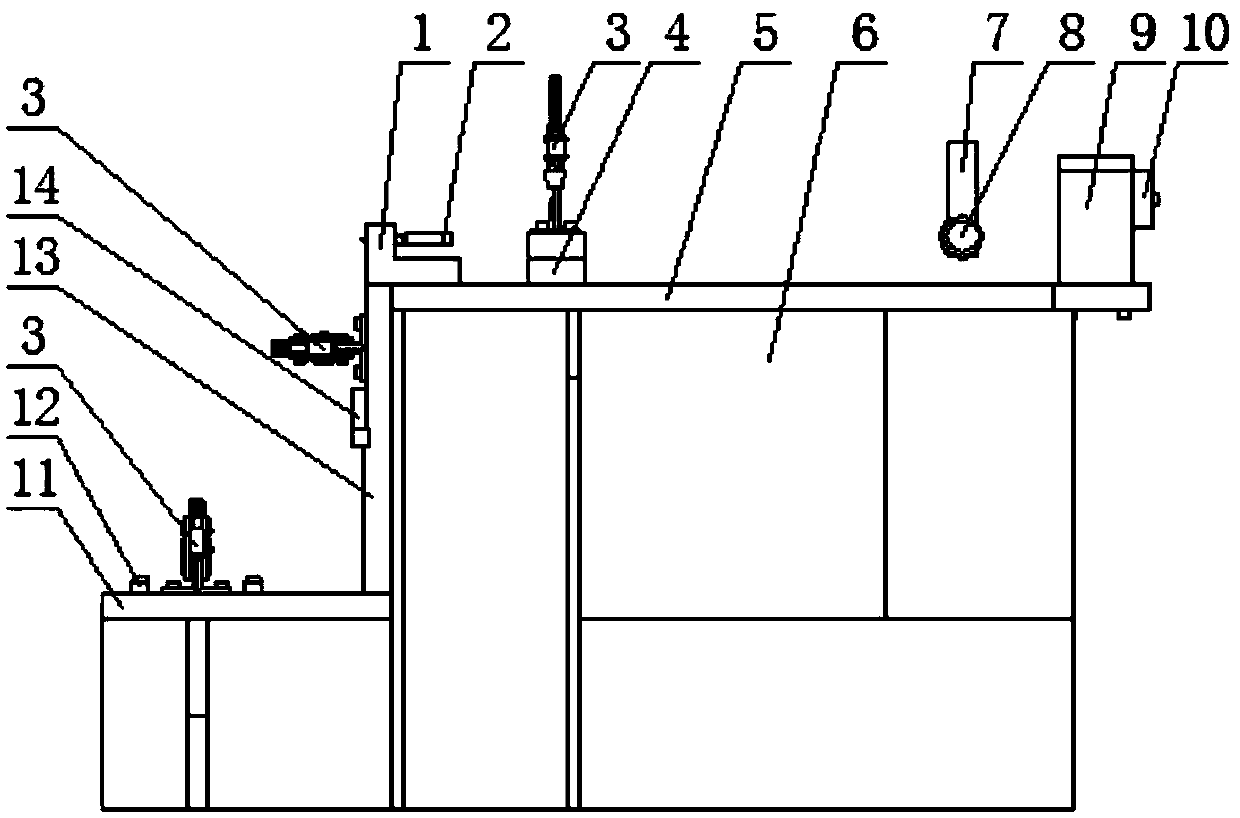

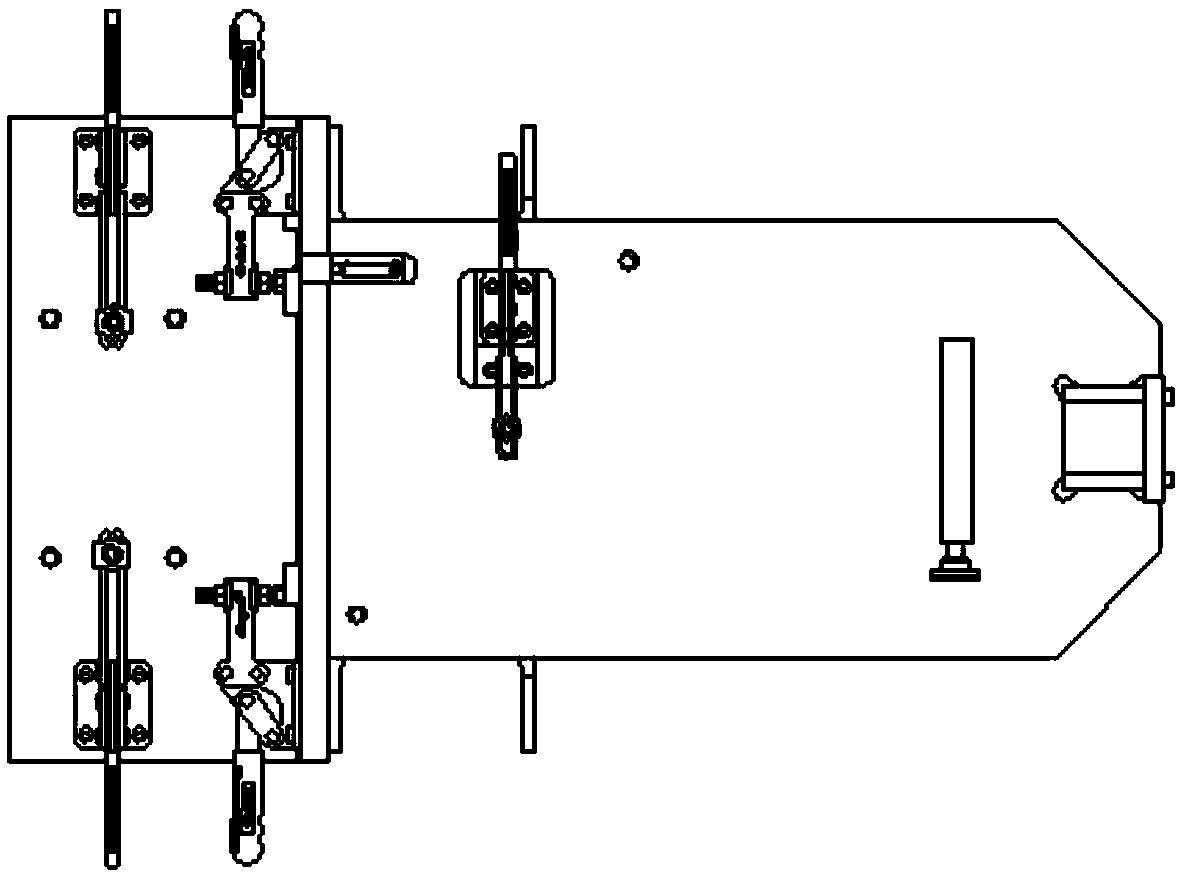

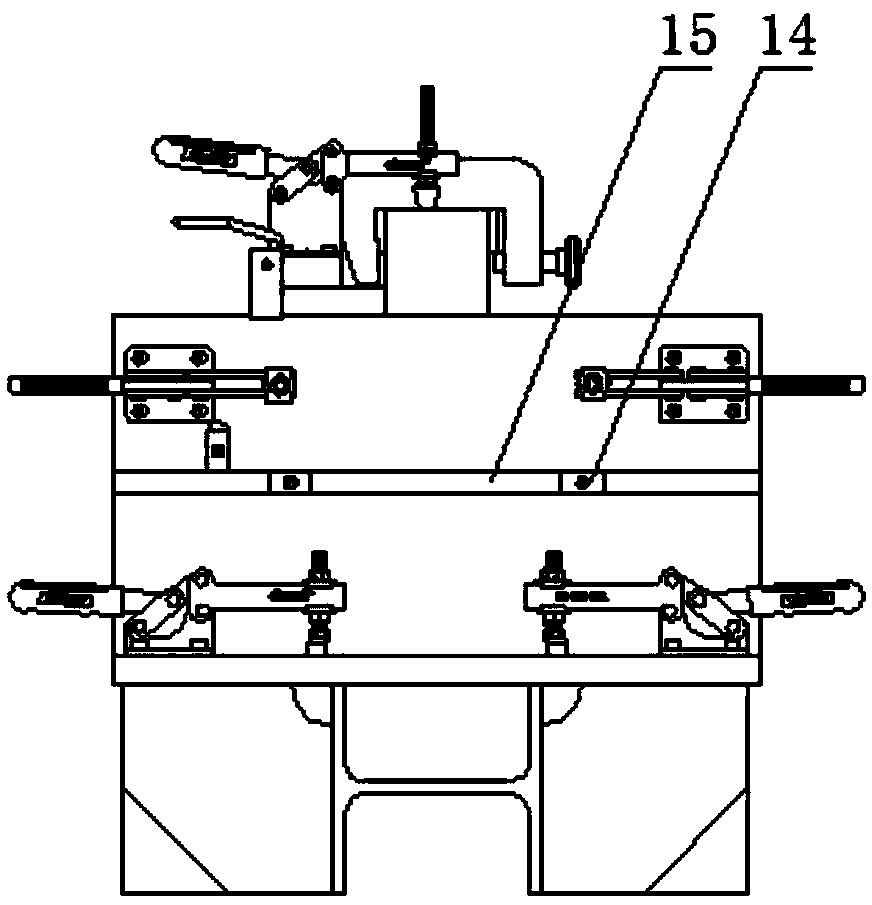

[0023] A device for positioning and installing a corner bracket, comprising a base 6, a workbench, a clip positioning and pressing mechanism, a beam positioning and pressing mechanism, a side plate positioning and pressing mechanism, and a curved beam positioning and pressing mechanism. The workbench is formed by connecting the upper water platform 5, the vertical platform 13 and the lower water platform 11 successively. The horizontal platform surface is installed on the left side surface of the base, and the lower water platform surface is lower than the upper water platform surface.

[0024] The right side of the upper surface of the upper water platform is provided with a clamp positioning and pressing mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com