Dust collecting device

A dust collection device and dust collection technology, applied in the direction of cleaning devices, transportation and packaging, conveyor objects, etc., can solve the problems of many dust particles, pollute the environment, hidden safety hazards, etc., achieve high dust collection efficiency and avoid environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

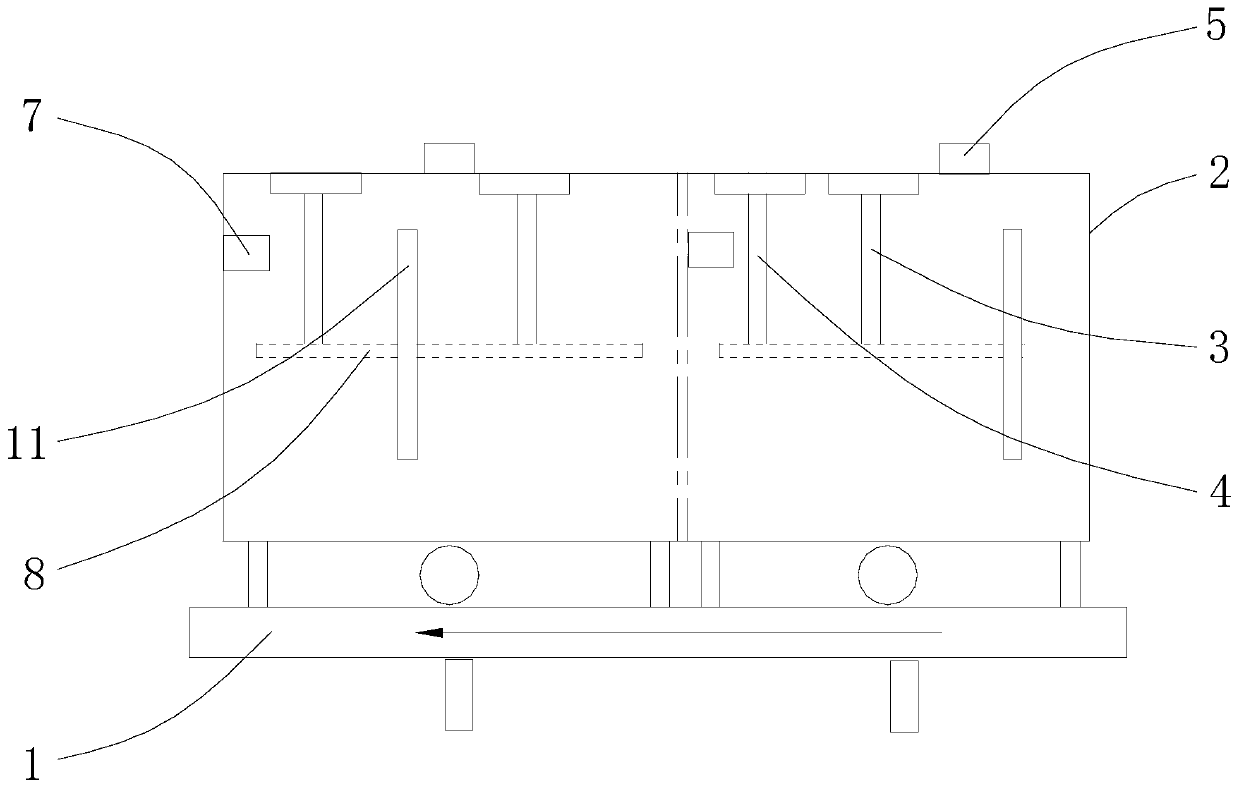

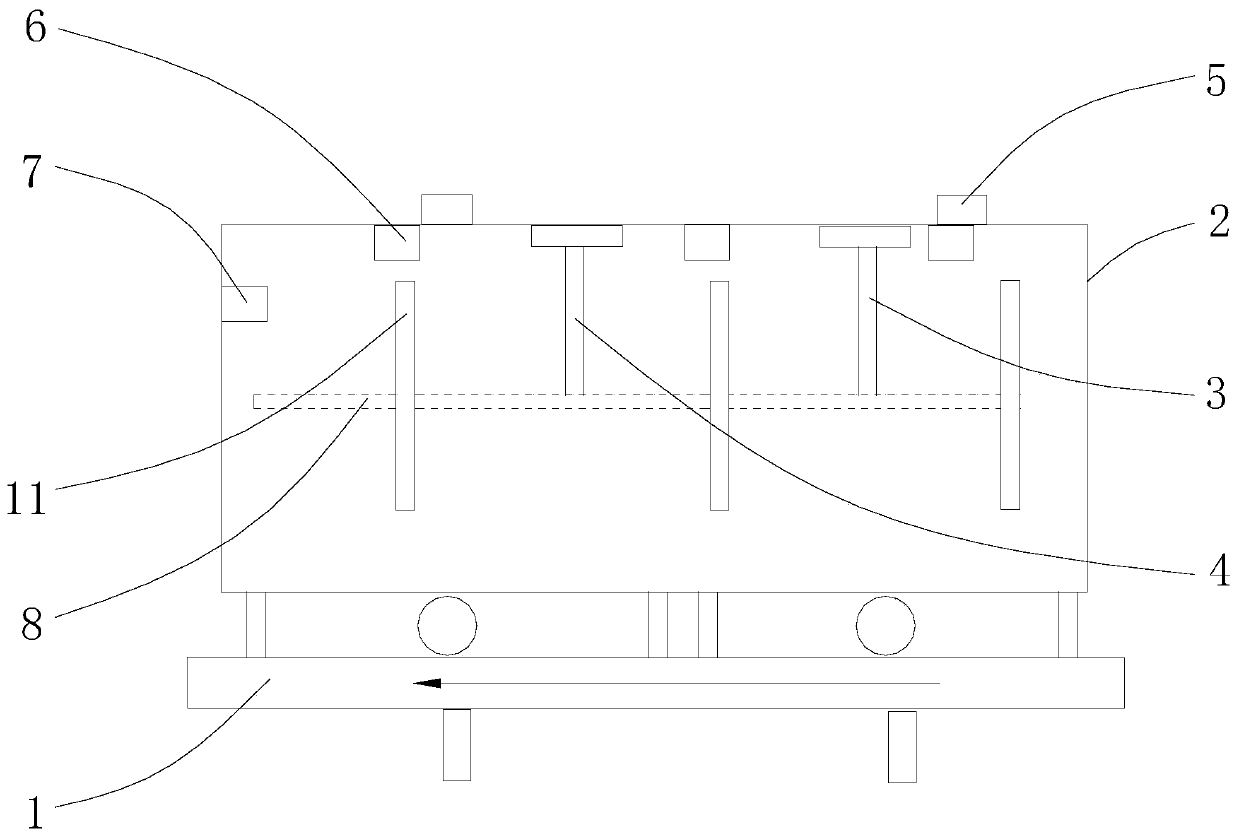

[0029] see Figure 1-4 As shown, the above-mentioned dust collection device is used for the belt conveyor 1, and the device includes at least one dust collection unit.

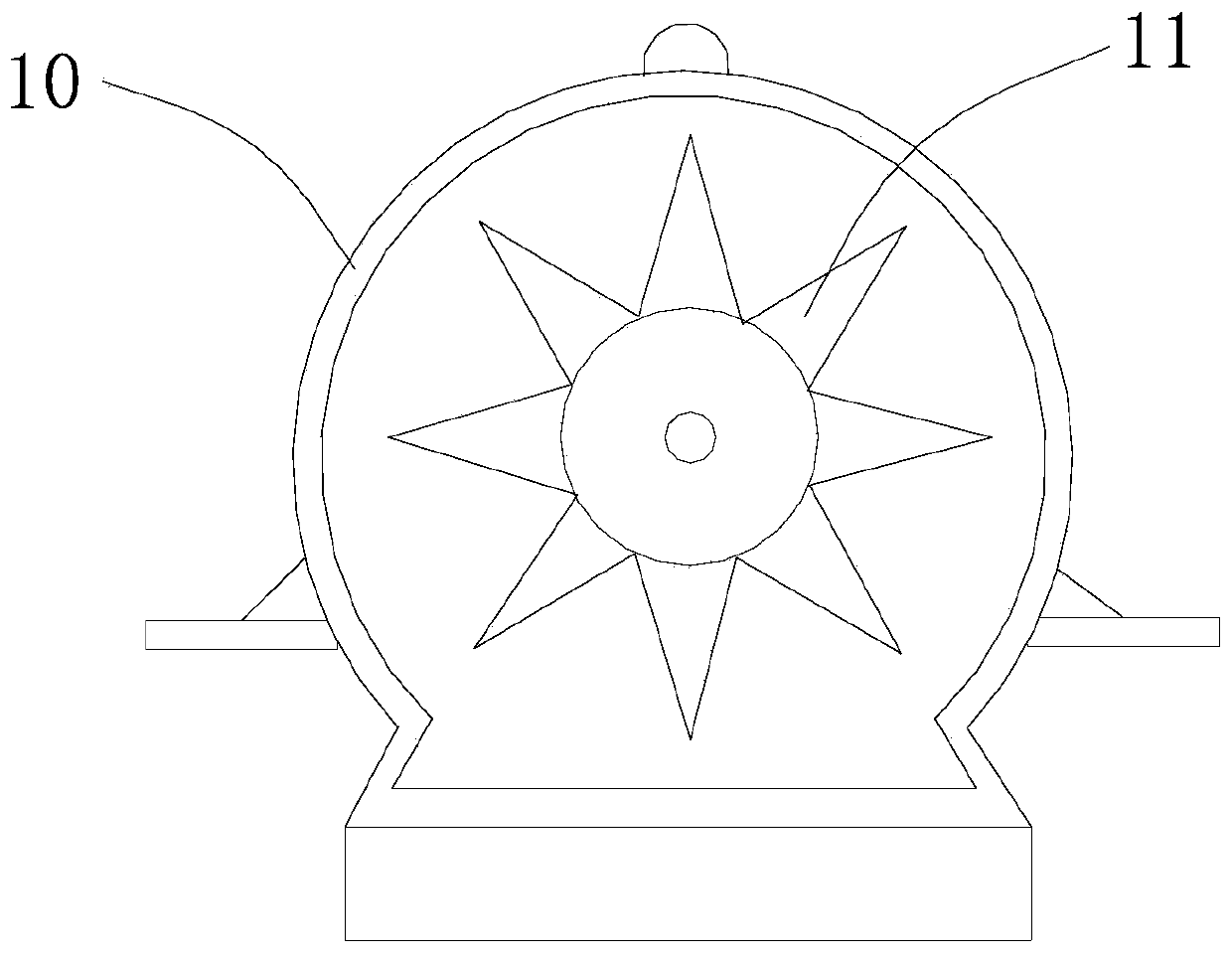

[0030] Each dust collection unit includes a casing 2 for covering the belt conveyor 1, an electrode 11 fixed in the casing 2, an insulating porcelain bottle 3 connected between the electrode 11 and the casing 2, and an insulating porcelain bottle 3 connected between the casing 2. 2 and the terminal 4 between the electrode 11, the vibrator 5 located on the housing 2; the insulating porcelain bottle 3 is insulated and connected to the electrode 11 and the housing 2, the terminal 4 is electrically connected to the electrode 11, and is connected to the housing 2 Insulated connection.

[0031] When the above-mentioned dust collecting unit is working, there is a potential differen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com