Multi-nozzle rocket jet test system

A test system and multi-nozzle technology, which is used in the test of ammunition, rocket launchers, offensive equipment, etc., can solve problems such as inability to guide the engineering design of the rocket body and ground launch system, inability to reflect the noise environment, and ignoring disturbance effects. , to achieve the effect of reducing the layout location and number of layouts, ensuring accuracy and reliability, and ensuring similarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in detail below in conjunction with the accompanying drawings and examples.

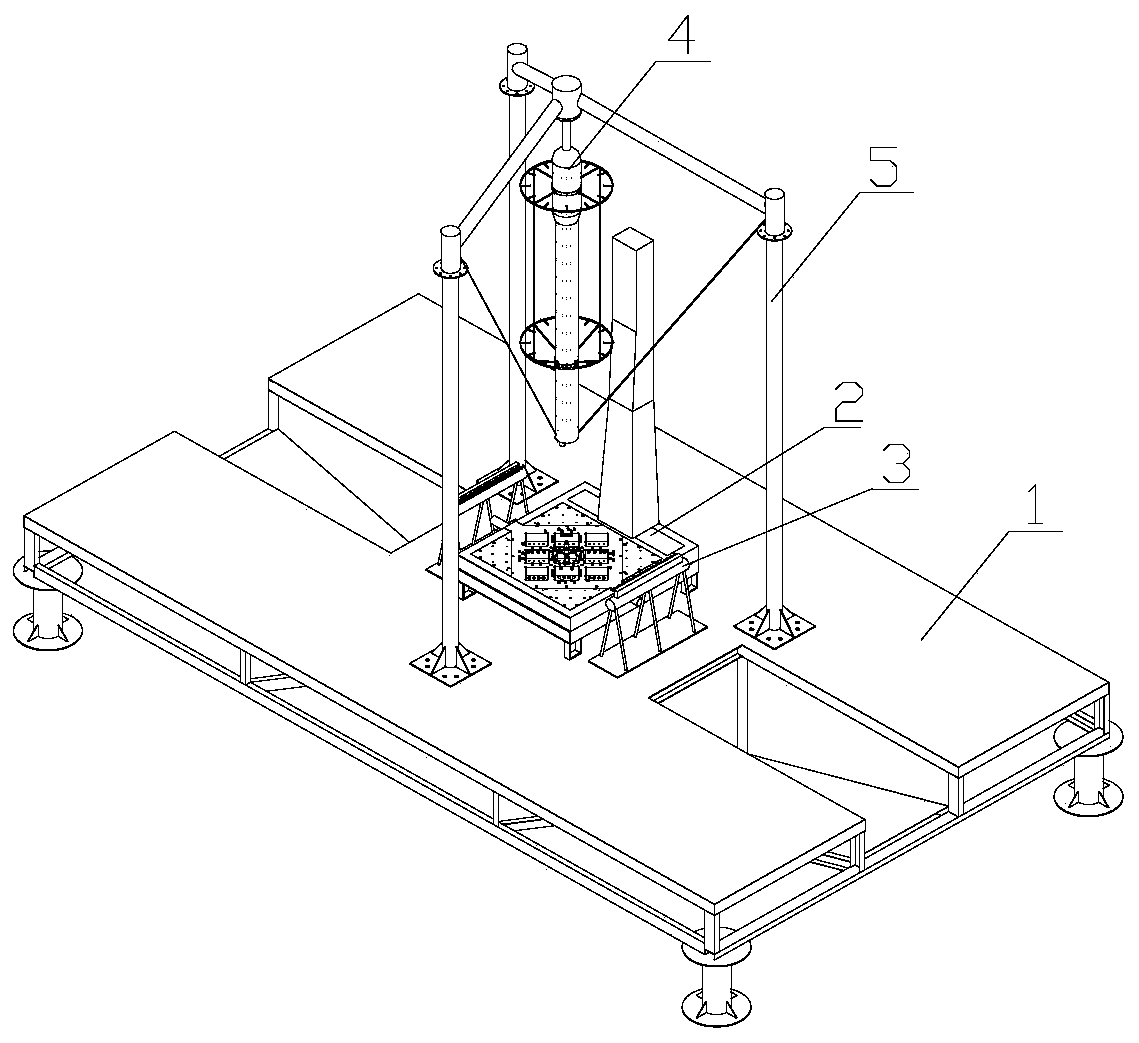

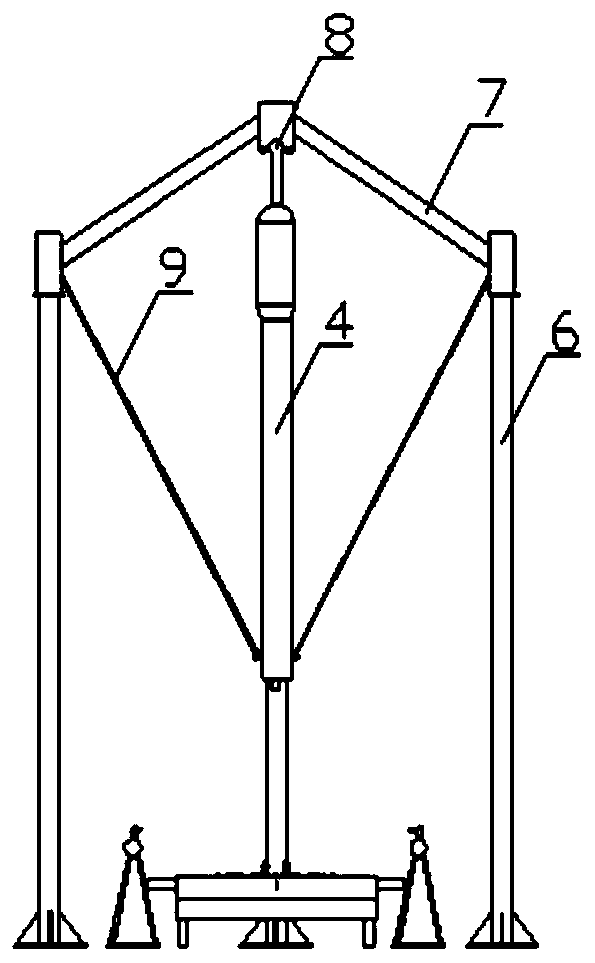

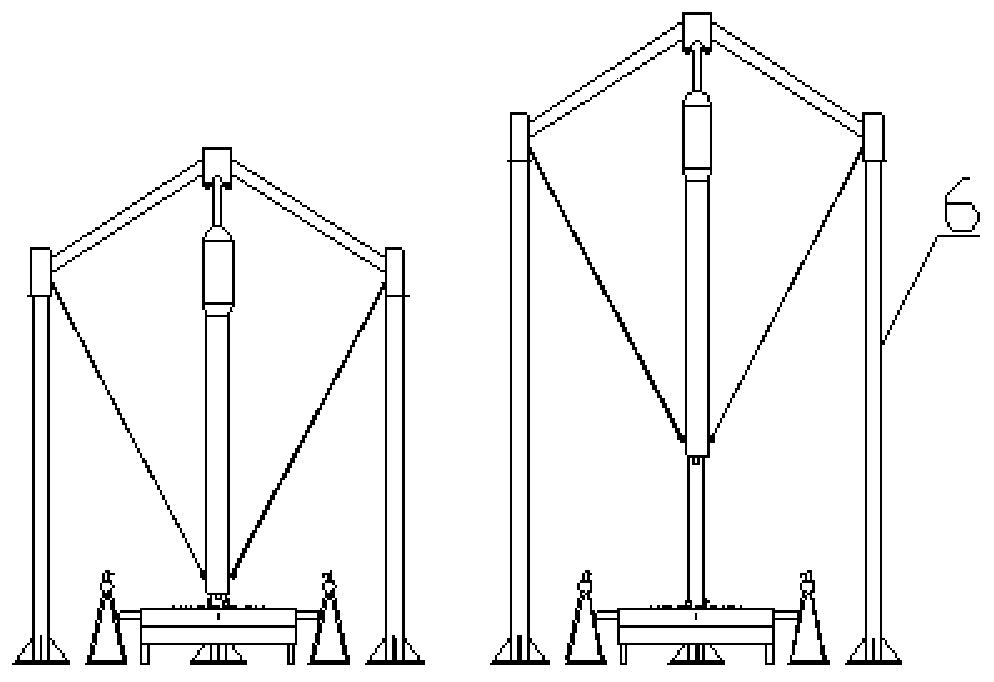

[0045] 1) The outline of the jet test system remains similar to that of the original launch vehicle and launch support system

[0046] In order to ensure that the gas flow field, the thermal environment of the take-off force and even the distribution of the noise field, the noise reduction effect of water spray, and the thermal protection performance of the launch system are consistent with the actual launch vehicle and launch support system, the outline of the jet flow test system should be fully consistent with the actual product. similarity. At the same time, the water spray flow and water spray speed of the water spray noise reduction system should match the test system. Of course, in order to reduce the scale of the jet flow test, on the premise of satisfying the similarity of the gas flow field and the thermal environment of the take-off force, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com