Resin sealing mold adjusting method and resin sealing mold

A technology of resin sealing and adjustment method, which is applied to the adjustment of resin sealing molds and the field of resin sealing molds, which can solve the problems of economic burden on stamping devices, labor required for operators, and high mold prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

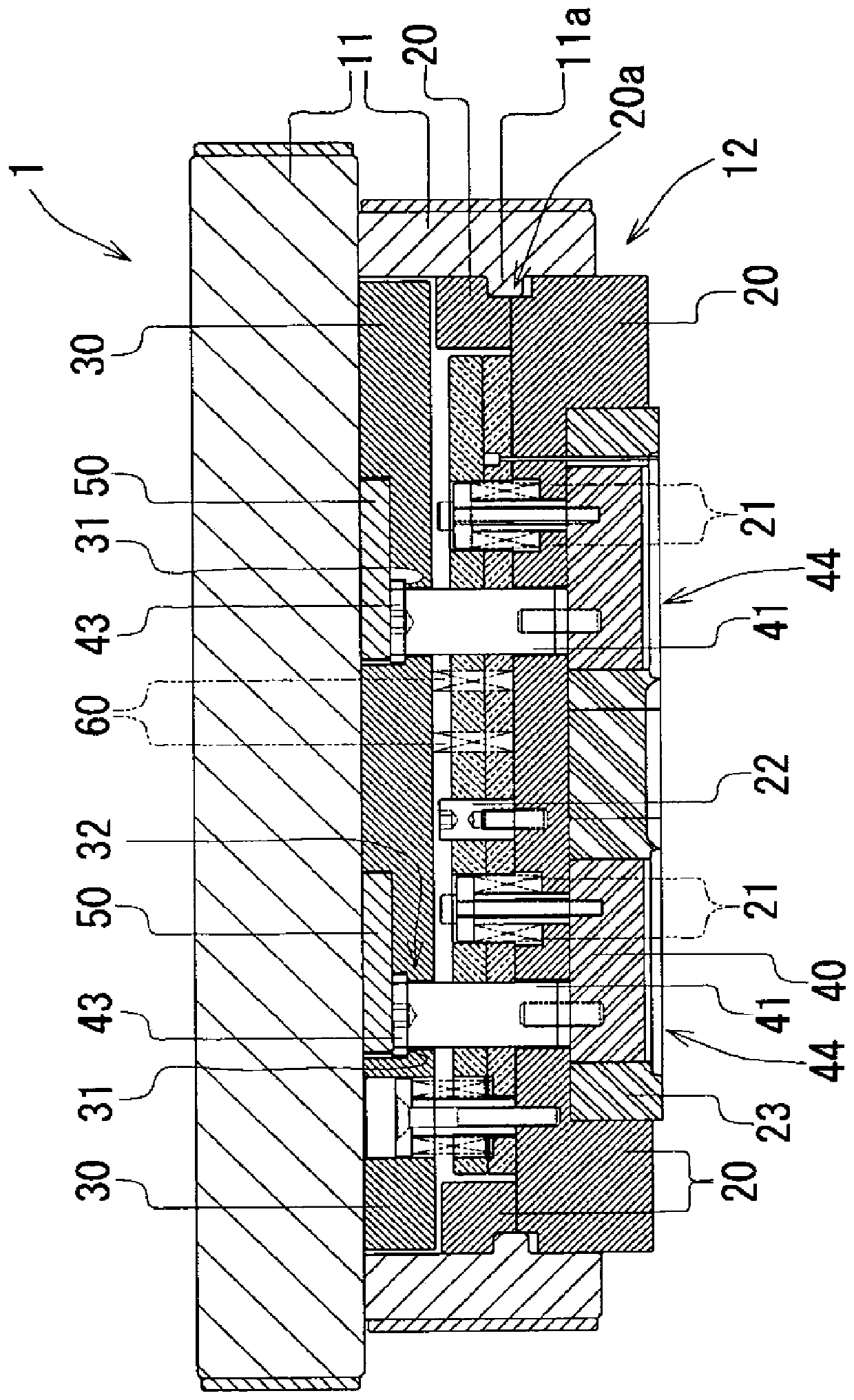

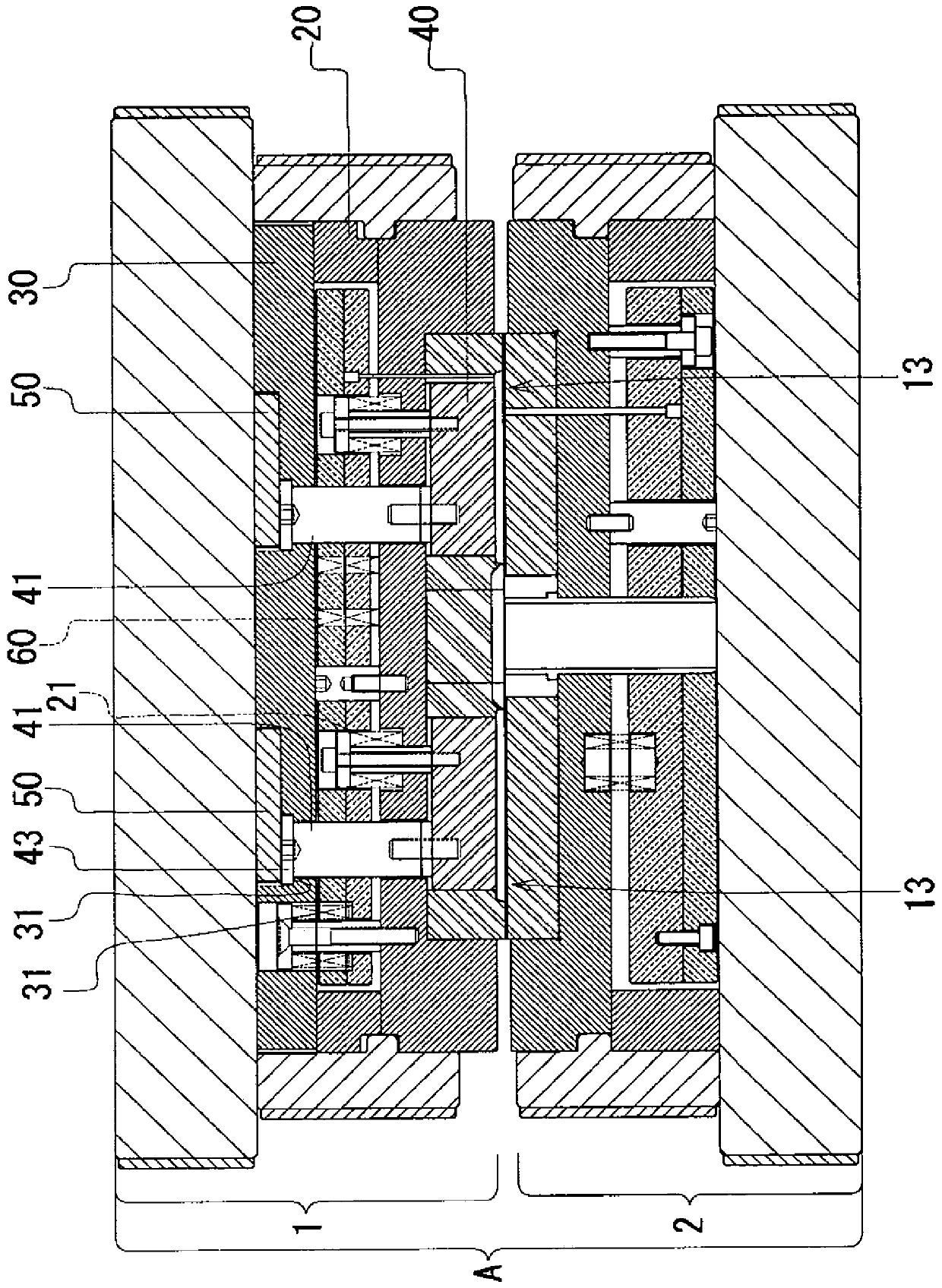

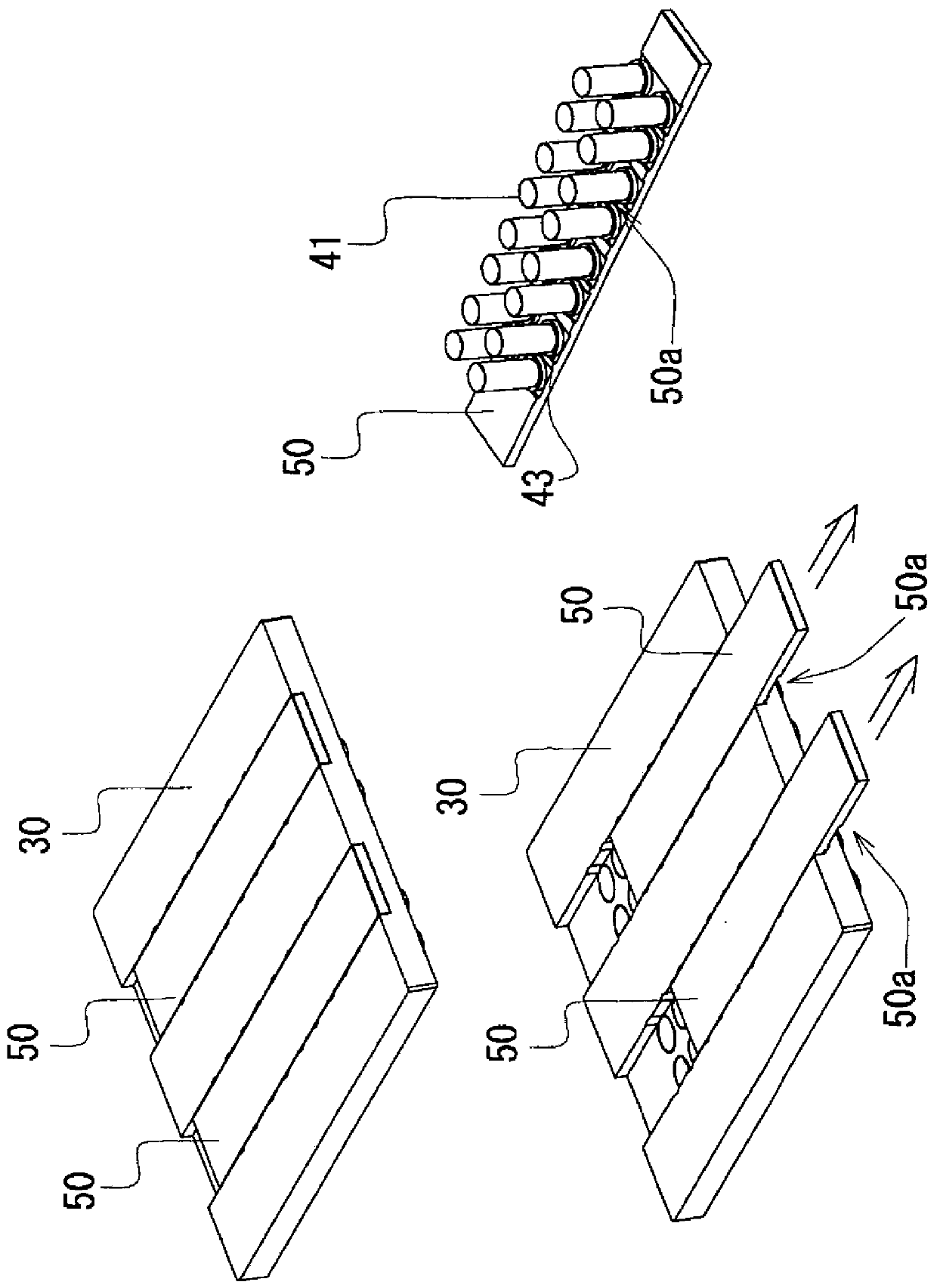

[0046] The first embodiment described below is an example in which the height of the cavity is adjusted by replacing the spacer 50 with another spacer 51 from a state in which the spacer 50 is installed in the upper mold 1 . Therefore, in the first embodiment, first, the structure of the upper mold 1 incorporating the spacer 50 (refer to figure 1 ) and the structure when using the upper mold 1 to close the mold (refer to figure 2 )Be explained. Then, the change from the spacer 50 to the spacer 51 and the structure of the upper mold 1 replaced by the spacer 51 (refer to Figure 4 ), the structure when using the upper mold 1 changed to the spacer 51 for mold clamping (refer to Figure 5 )Be explained.

[0047] figure 2 It is a schematic diagram for explaining an example of a mold for resin sealing to which the present invention is applied, and the mold A shown here is composed of an upper mold 1 and a lower mold 2 (see figure 2 ). The upper mold 1 and the lower mold 2 a...

no. 2 approach

[0081] Next, a second embodiment of the mold for resin sealing to which the present invention is applied will be described. In addition, in the following, detailed descriptions of the configurations that overlap with those of the first embodiment that have already been described will be omitted, and the configurations that differ from those of the first embodiment will be mainly described.

[0082] Such as Figure 6 and Figure 7 As shown, in the second embodiment of the resin sealing mold to which the present invention is applied, in the structure of the upper mold 101, the same as the above-mentioned upper mold 1, the holder base 120 uses the spring member 121 to hold the package insert 140 Keep it so that it does not fall off downward.

[0083] In addition, the upper mold 101 is different from the upper mold 1 in that no flange receiving portion is provided on the bottom plate 130 and no flange portion is provided on the connector 141 . That is, the upper mold 101 has a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com