Water purifier, water purifier holder, and water purifier filter cartridge

A technology of water purifiers and filter cartridges, which is applied in water/sewage treatment, adsorption water/sewage treatment, water/sewage treatment equipment, etc. It can solve the problems of large outer diameter of the result cartridge and inability to ensure cabinet storage space, etc., to achieve Effect of reducing pressure loss and preventing water leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

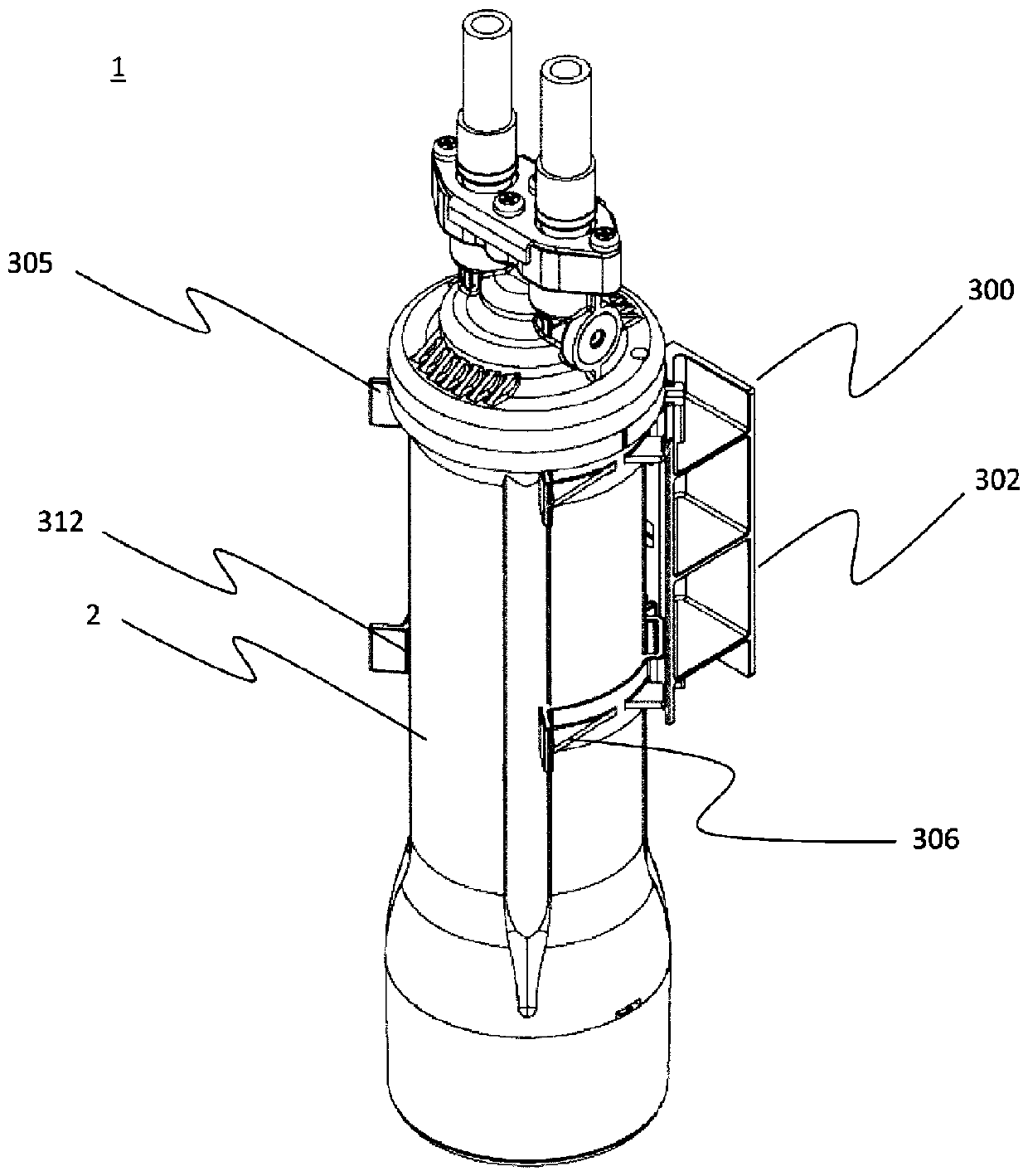

[0179] Coconut shell activated carbon is used as a powder filter material. The particle diameter D50 when the cumulative value based on the particle size distribution of the volume becomes 50% is 197 μm, the particle diameter D90 when the cumulative value based on the particle size distribution of the volume becomes 90% is 295 μm, and the cumulative value based on the particle size distribution of the volume becomes 10% The particle size D10 is 141 μm. fill the activated carbon with image 3 In the filter cartridge of the structure, measure to show the pressure loss value (1) when the flow rate is 3.5L / min. Then, measure the pressure loss value (2) of the filter cartridge after removing the powder filter material, subtract the pressure loss value (2) from the pressure loss value (1), and calculate the pressure loss value of the powder filter material part (3 ). As a result, the pressure loss in the powder filter section becomes very small.

Embodiment 2)

[0181] In addition to the particle size D50 of 211 μm when the cumulative value based on the particle size distribution of the volume is 50%, the particle diameter D90 of 319 μm when the cumulative value of the volume based on the particle size distribution is 90%, and the particle size based on the volume The pressure loss was measured in the same manner as in Example 1, except for the coconut shell activated carbon whose particle size D10 was 143 μm when the cumulative value of the distribution was 10%. The pressure loss was higher than in Example 1, but there was no practical problem.

reference example 1)

[0183] In addition to the particle size D50 of 199 μm when the cumulative value based on the particle size distribution of the volume is 199 μm, the particle size D90 of 319 μm when the cumulative value of the volume based on the particle size distribution is 90%, and the particle size based on the volume. The pressure loss was measured in the same manner as in Example 1, except for the coconut shell activated carbon whose particle size D10 was 116 μm when the cumulative value of the distribution was 10%. The pressure loss is higher than 0.018MPa.

[0184] The conditions of the powder filter materials of Examples 1, 2 and Reference Example 1 are summarized in Table 1, and the pressure loss values are summarized in Table 2. There is no practical problem if the pressure loss value (3) at the time of passing water at 3.5 L / min in the powder filter part is 0.018 MPa or less.

[0185] [Table 1]

[0186] Particle size D10 [μm] Particle size D50 [μm] Particle size D...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap