A high pressure separator

A high-pressure separator and tank technology, which is applied in the field of intelligent manufacturing, can solve the problems of reduced efficiency of liquid flowing into the separator, aggravated pipeline blockage, increased water surface fluctuations, etc., and achieves the effects of stable connection, increased buffering force, and calm water flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

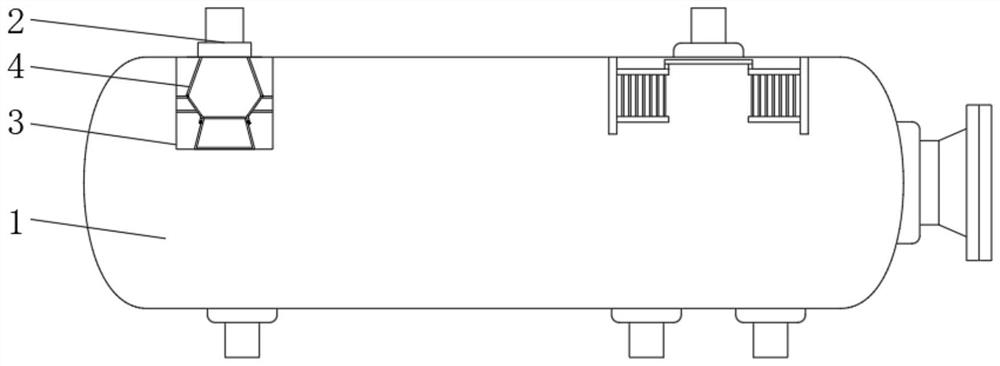

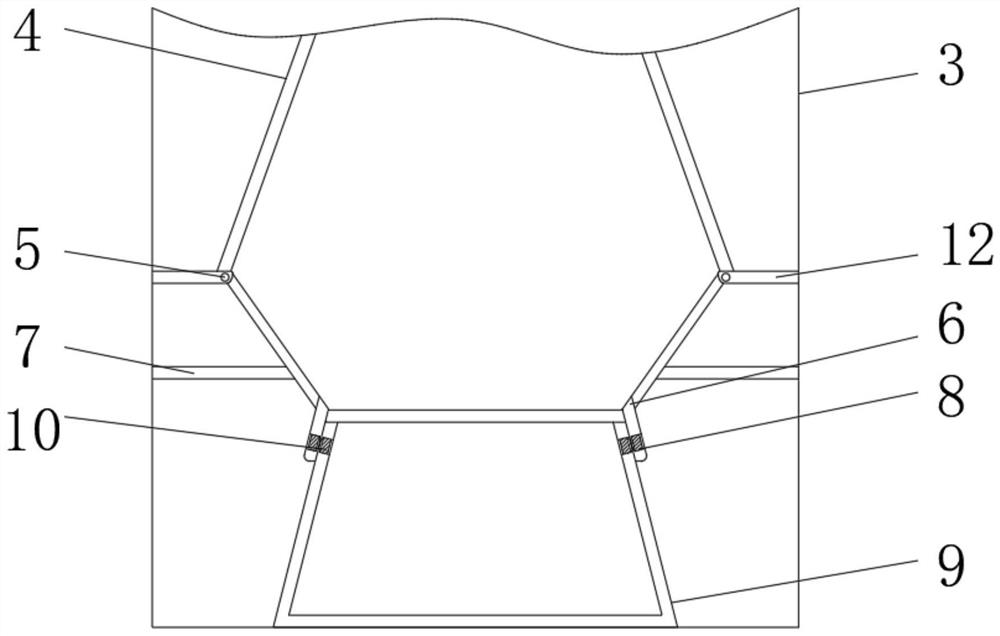

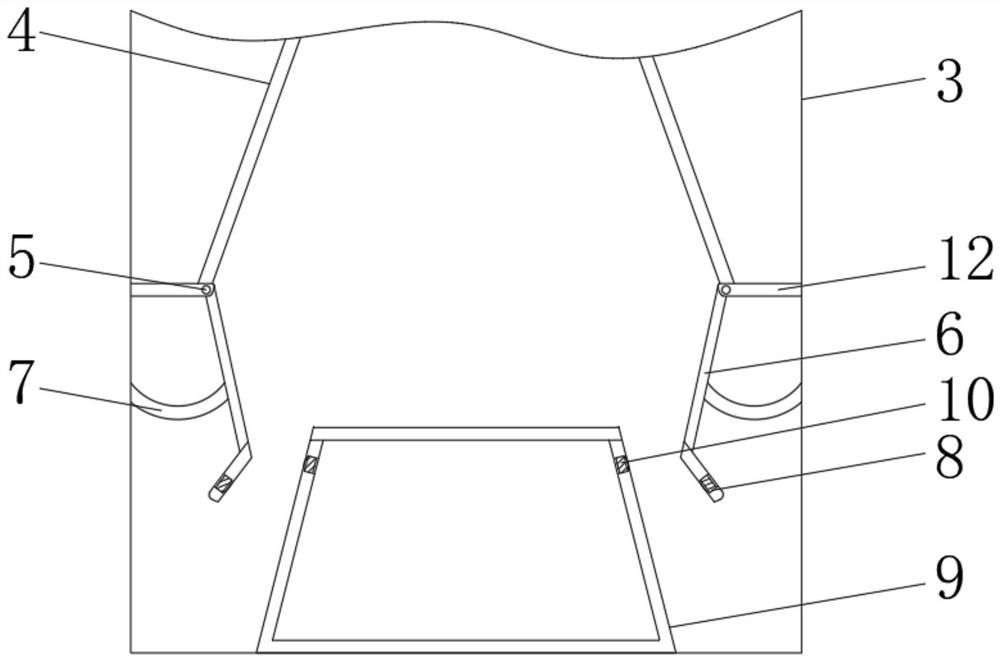

[0019] See Figure 1-4 A high pressure separator, including a can body 1, a feed tube 2, and a feed tube 2 mounted on top of the can body 1, and a tank body is mounted, a cassette 3 is mounted, and the cassette 3 is rectangled, and the cartridge 3 is installed. There is a guide plate 4, which is inverted, facilitating the diffusion of the water flow, so that the area after the flow of water flows into large, the cassette 3 is mounted with a positioning plate 12 at the bottom of the guide plate 4, the positioning plate 12 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com