A spindle-shaped passive micro-mixer

A spindle-shaped, mixer technology, applied in fluid mixers, mixers, chemical instruments and methods, etc., can solve the problems of complicated processing and manufacturing processes, large pressure drop in microchannels, and violent fluid disturbances, and improve the mixing effect. , increase the contact area and improve the effect of the disturbance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

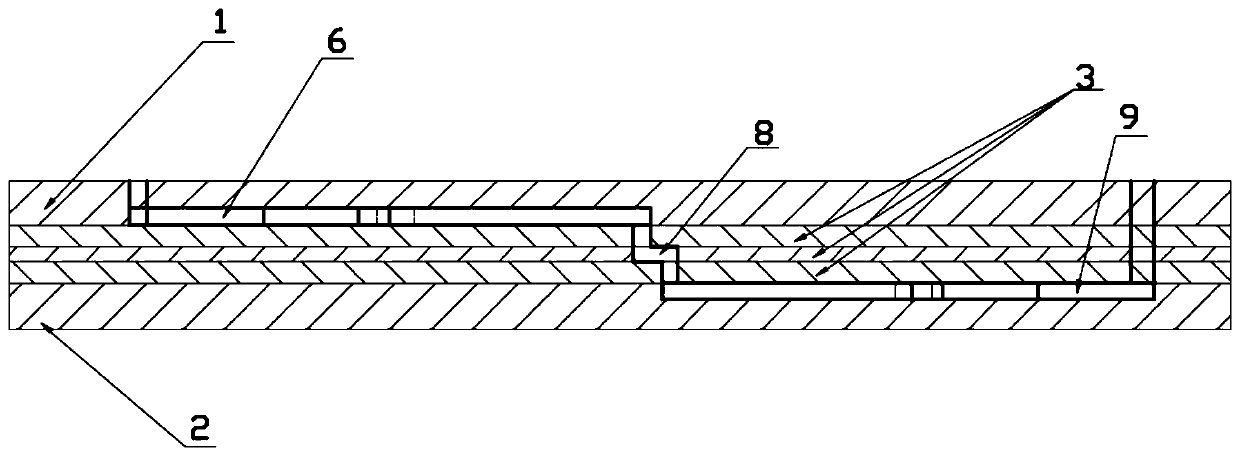

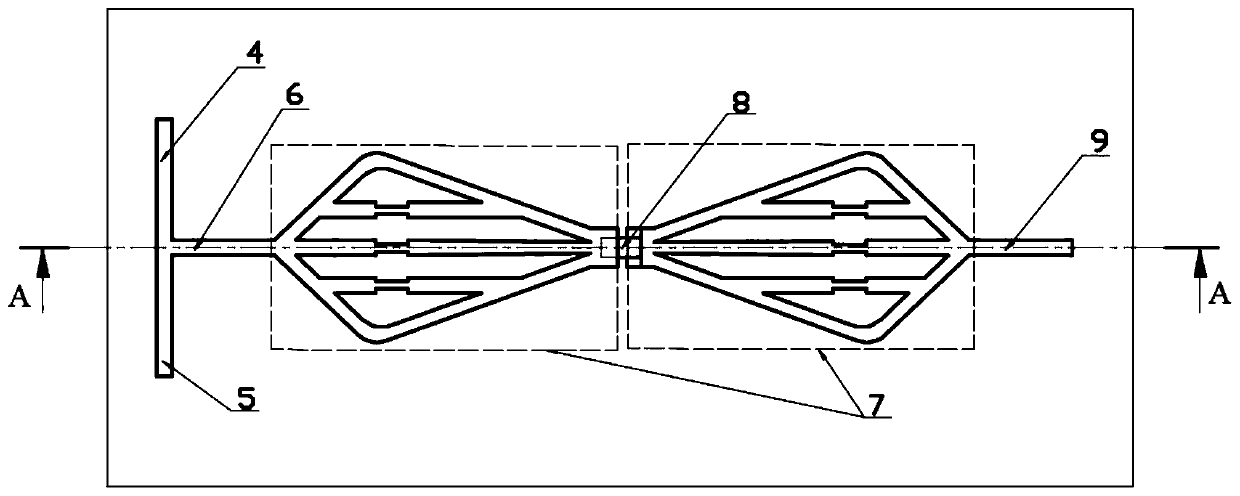

[0035] In a typical implementation of the present application, such as figure 1 As shown, a spindle-shaped passive micro-mixer, a cover plate 1, a base body 3 and a bottom plate 2 are sequentially arranged from top to bottom, and a spindle-shaped mixing unit 7 is respectively arranged on the cover plate and the bottom plate, and the cover plate 1 There is a first inlet channel 4, a second inlet channel 5, a first channel and a spindle-shaped mixing unit 7, the first channel here is a straight channel 6, after the first inlet channel and the second inlet channel merge, through the straight Road 6 communicates with the spindle-shaped mixing unit on the cover plate, and a spindle-shaped mixing unit 7 with the same structure as the spindle-shaped mixing unit on the cover plate is also provided on the base plate, and the first channel is also provided on the base plate, The first passage here is the outlet passage 9, and the third passage is provided on the base body, and the third...

Embodiment 2

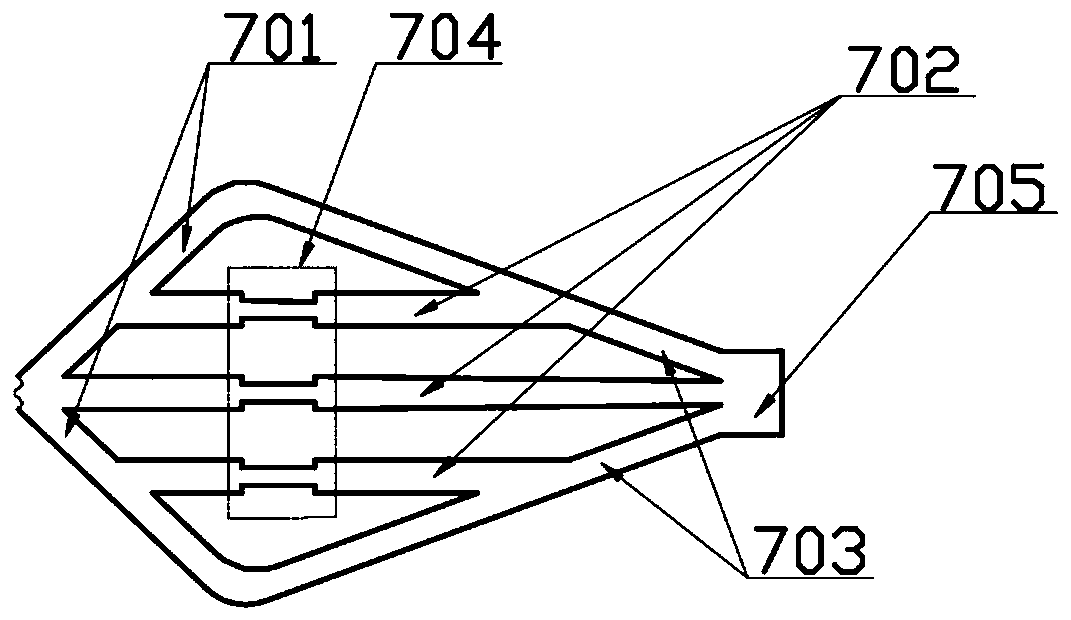

[0042] In the second embodiment of the present application, if figure 2 and image 3 As shown, the difference from Embodiment 1 is the spindle-shaped mixing unit, which includes the second channel and the confluence part 705 connected in sequence; the second channel includes a side channel and a first middle channel, and the side channel has two , arranged in a spindle shape, the intersection point of the short side channel 701 of the two side channels is connected to one end of the first channel, the intersection point of the long side channel 703 of the two side channels is connected to the confluence 705, and the middle channel 702 is connected to the short side The intersection point of and the intersection point of the long side, the first channel, the first intermediate channel and the confluence part 705 have a common axis;

[0043] The second channel also includes a second middle channel 702 provided on each side channel, one end of the second middle channel communic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com