Three-degree-of-freedom robot leg system based on synchronous belt drive

A timing belt transmission and degree of freedom technology, applied in the field of robotics, can solve problems such as large joint modules, achieve the effects of reducing weight, improving dynamic response characteristics, and ensuring structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

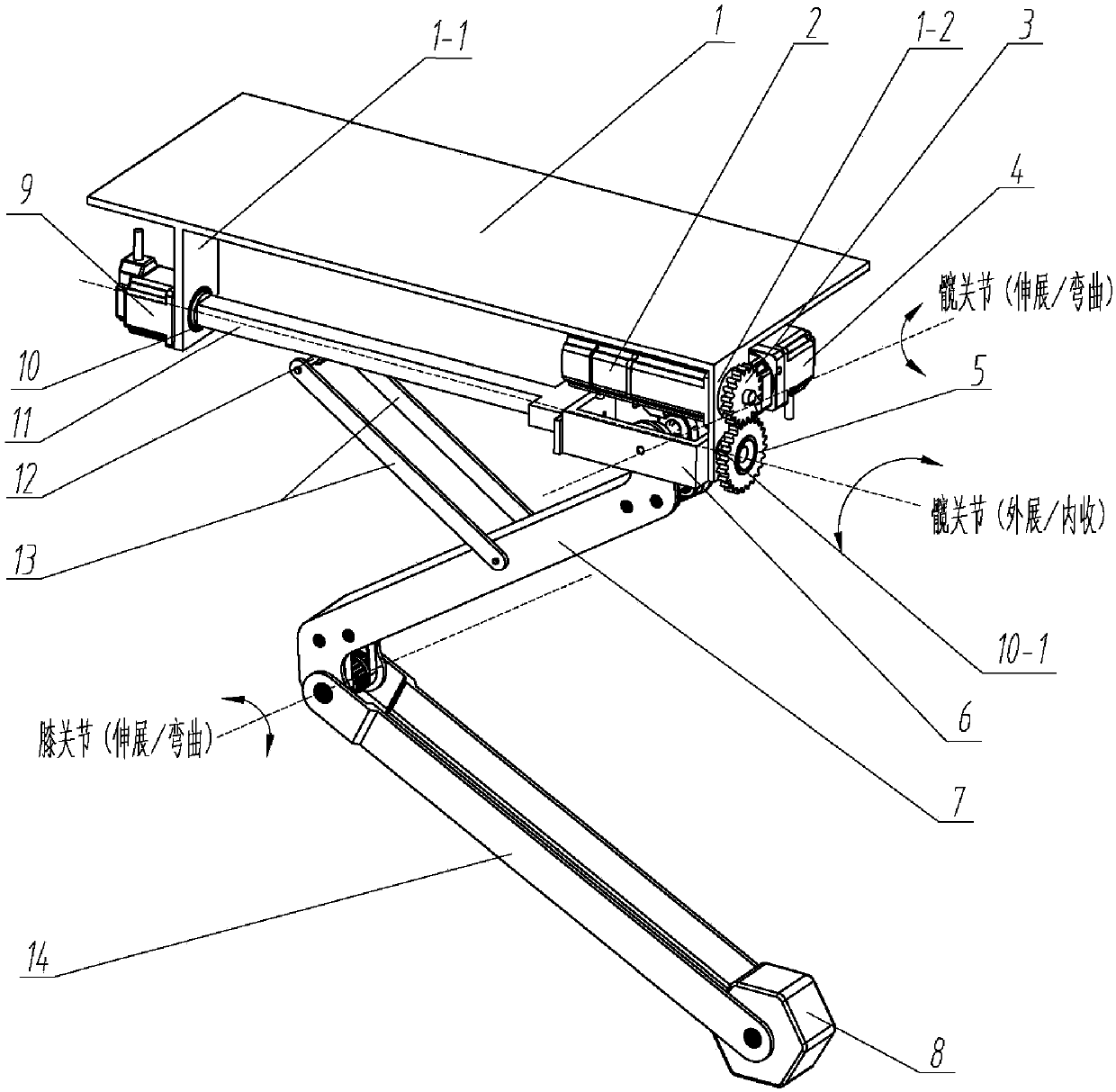

[0043] image 3 Among them, two mounting plates protrude from the lower side of the robot body, which are connected with the ball screw mounting rod seat through the bearing;

[0044] The hip joint "abduction / adduction" driving motor and its integrated gear box are also installed on the mounting plate on the lower side of the robot body, and the driving force of the joint "abduction / adduction" is transmitted to the hip joint "outside" through gears and gears. "Extension / Adduction" motion base;

[0045] The "abduction / adduction" movement base of the hip joint is fixedly connected with the ball screw mounting rod seat; the front end of the ball screw mounting rod seat protrudes through the inner ring of the bearing, and the hip joint "extension / bending" driving motor is installed;

[0046] Such as Figure 4 As shown in the figure, the screw installed inside the ball screw mounting rod base rotates under the drive of the motor to push the ball screw nut to move left and right; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com