A special fertilizer for sea rice and its manufacturing method

A manufacturing method and technology for special fertilizers, applied in the fields of application, potash fertilizers, nitrogen fertilizers, etc., can solve problems such as increasing fertilizer production costs, achieve significant promotion and application value, increase utilization rate, and reduce ammonia volatilization loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

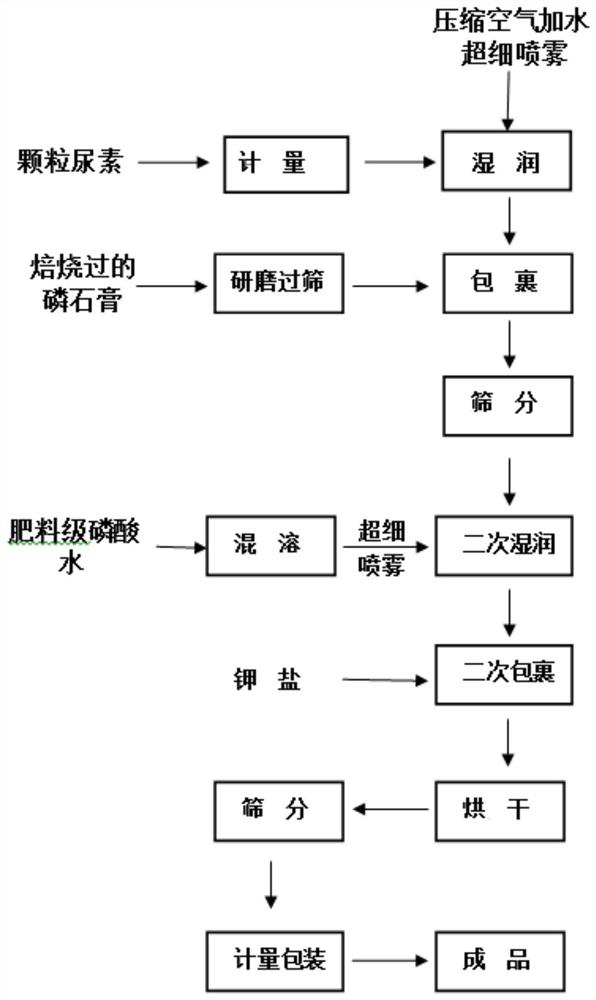

[0030] A kind of manufacture method of special fertilizer for seawater rice, the technological process of its manufacture is as follows figure 1 As shown, the granular urea with a particle size of Ф0.85~2.8mm is metered, and the water is ultra-finely sprayed on the granular urea under the action of the compressed air flow to wet the surface of the granular urea. The calcined phosphogypsum is ground to a powder passing through a 0.074mm sieve through ultra-fine grinding technology to form ultra-fine phosphogypsum powder, which is coated with granular urea wetted with water, and then sieved and dedusted. A certain amount of fertilizer-grade phosphoric acid is miscible with water, and is sprayed ultra-finely under the action of compressed air flow to wet the surface of granular urea wrapped with phosphogypsum, and then use powdered potassium chloride to carry out secondary treatment on the wet wrapped granular urea. The secondary coat is wrapped and dried. After screening and de...

Embodiment 2

[0032] A kind of manufacture method of special fertilizer for seawater rice, the technological process of its manufacture is as follows figure 1 As shown, the granular urea with a particle size of Ф1.18-3.35mm is metered, and the water is ultra-finely sprayed on the granular urea under the action of the compressed air flow to wet the surface of the granular urea. The calcined phosphogypsum is ground to a powder passing through a 0.074mm sieve through ultra-fine grinding technology to form ultra-fine phosphogypsum powder, which is coated with granular urea wetted with water, and then sieved and dedusted. A certain amount of fertilizer-grade phosphoric acid is miscible with water, and then sprayed ultra-finely under the action of compressed air flow to wet the surface of granular urea wrapped with phosphogypsum coating. The wet coated granular urea is coated with powdered potassium sulfate for a second time and dried. After screening and dedusting again, the granular fertilizer...

Embodiment 3

[0034] Using the same raw materials and preparation steps as in Example 1, the difference is:

[0035] (1) The air pressure of the compressed air used for wetting is 0.1Mpa, and the airflow velocity is 0.5m / s;

[0036] (2) The calcination temperature of phosphogypsum is 800°C, and the calcination time is 30min;

[0037] (3) The percentage concentration after fertilizer grade phosphoric acid is miscible with water is 25%;

[0038] (4) The temperature used for drying is 70° C., and the drying time is 20 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com