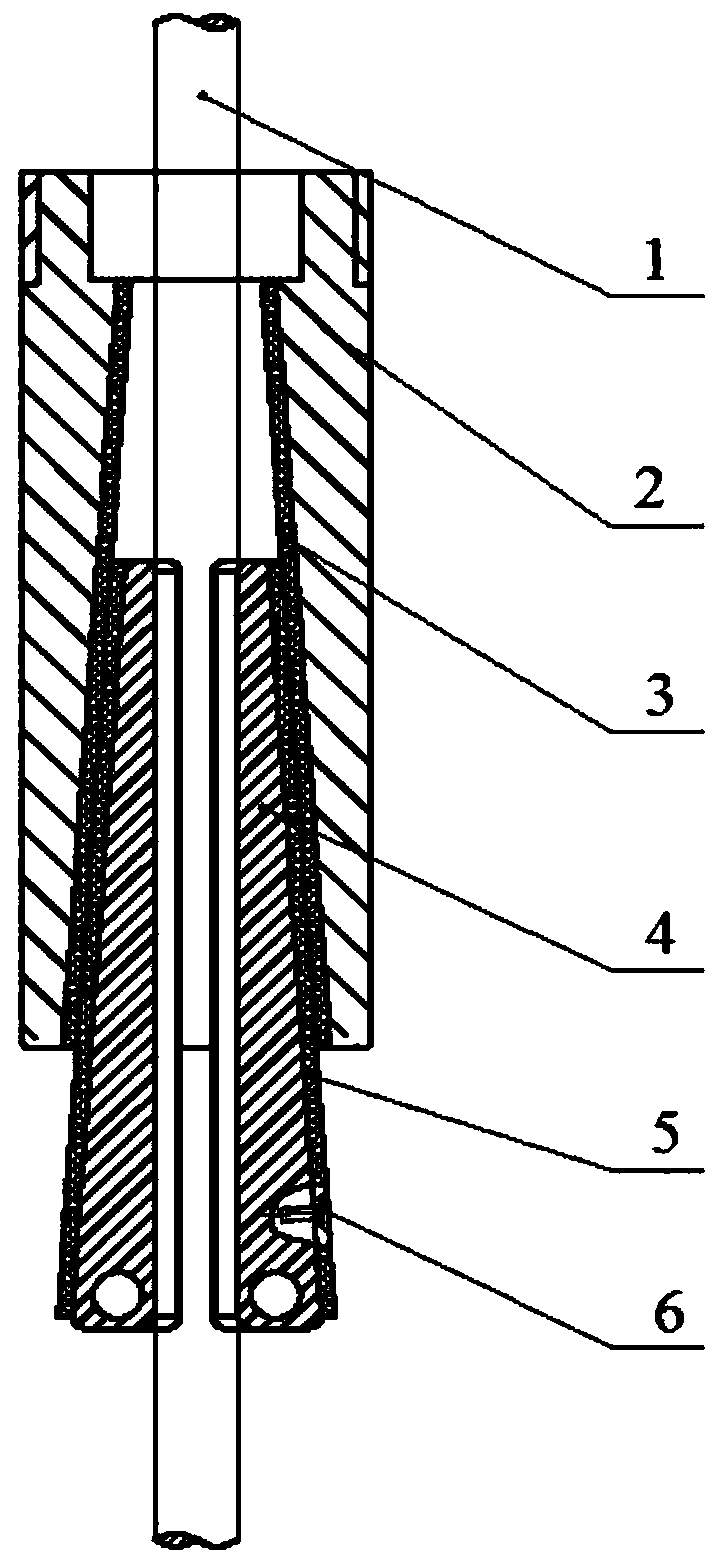

Linear tapered wedge rope locking device

A straight-line, oblique wedge technology, applied in the direction of transmission elements or pulley ropes or cables, textile cables, belts/chains/gears, etc., can solve problems such as large contact stress, reduction of the effective allowable load of the rope lock, and wire rope prolapse. , to achieve the effect of increasing the payload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

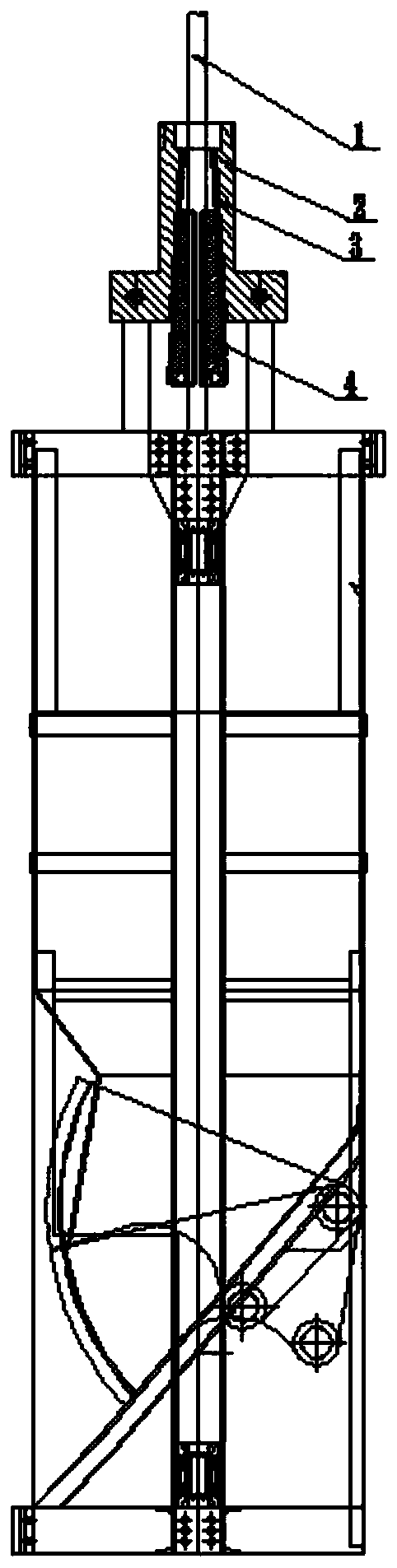

[0035] The inclined wedge rope locking device is used for vertical shaft single rope hoisting, replacing the traditional wedge rope ring device, see below for details image 3 .

[0036] When the traditional shaft is single-lifted, the container and the wire rope are usually connected by a wedge-shaped rope ring device. Because when the wedge-shaped ring device is connected to the wire rope, the wire rope must be bent through the connecting device, so it is difficult to connect the wire rope. The larger the diameter of the wire rope, the less easy it is to operate, and the wire rope in the bending transition section is easy to be injured. And adopt oblique wedge locking rope device of the present invention, can effectively overcome above-mentioned defect.

Embodiment 2

[0038] The wedge rope locking device of the present invention can also be used in the wire rope automatic balance suspension device, replacing the traditional ball structure, and the connection is more reliable.

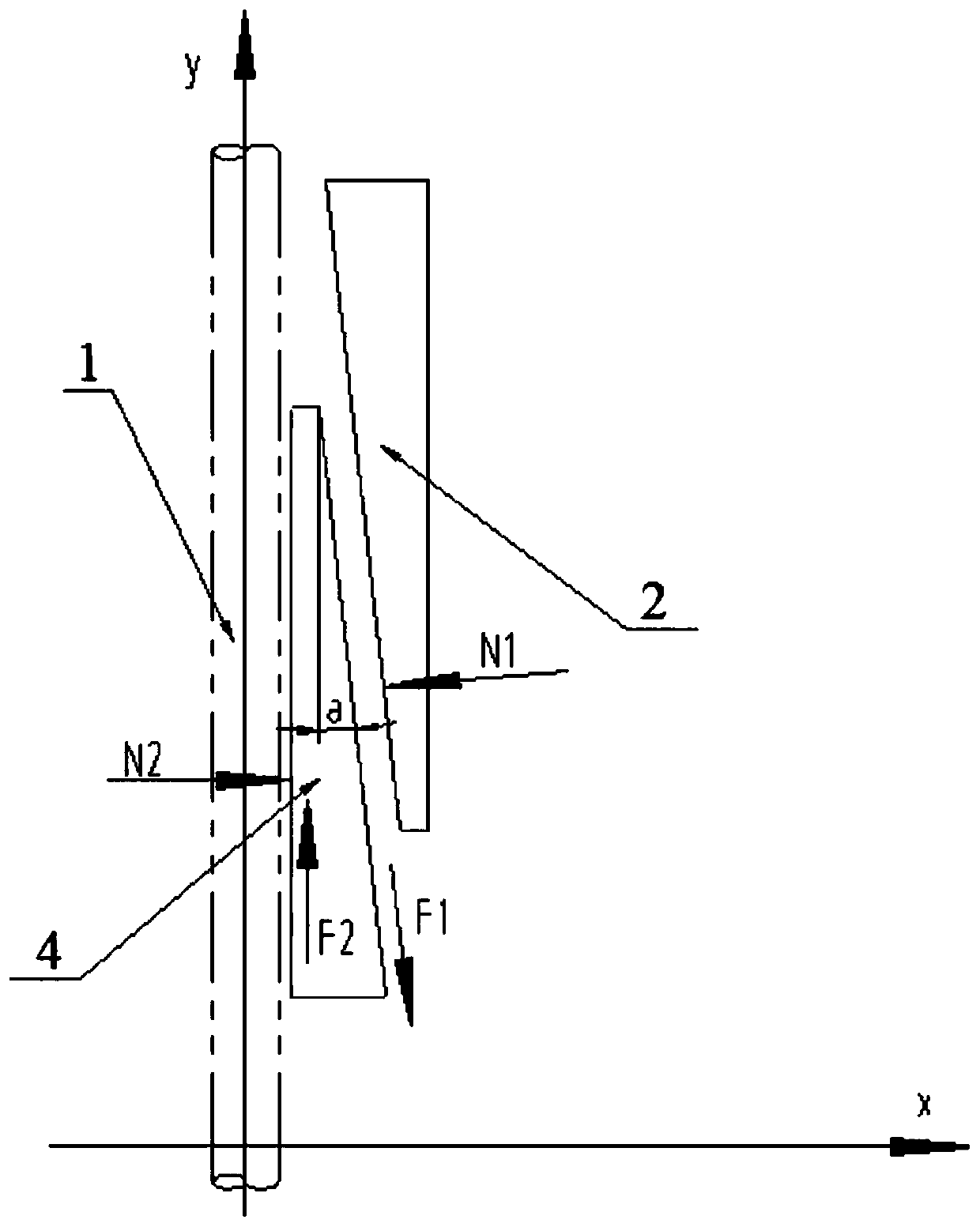

[0039] The invention provides a linear wedge rope locking device, which uses a material with a low friction coefficient instead of a conventional ball. At the same time, the sliding friction coefficient of this material is close to the original rolling friction coefficient, which can reach below 0.1, and can make the wire rope Reliably form self-locking with the rope lock, and at the same time greatly increase the effective load of the rope lock, avoiding the risk of the wire rope coming out of the rope lock due to damage to the ball or deformation of the wedge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com