Combined type flat-plate glass transportation frame

A technology of flat glass and transport racks, which is applied in the field of transport, can solve the problems of broken transport racks, partial stress, and transportation troubles, so as to enhance safety, enhance stability and structural strength, and reduce the possibility of detachment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

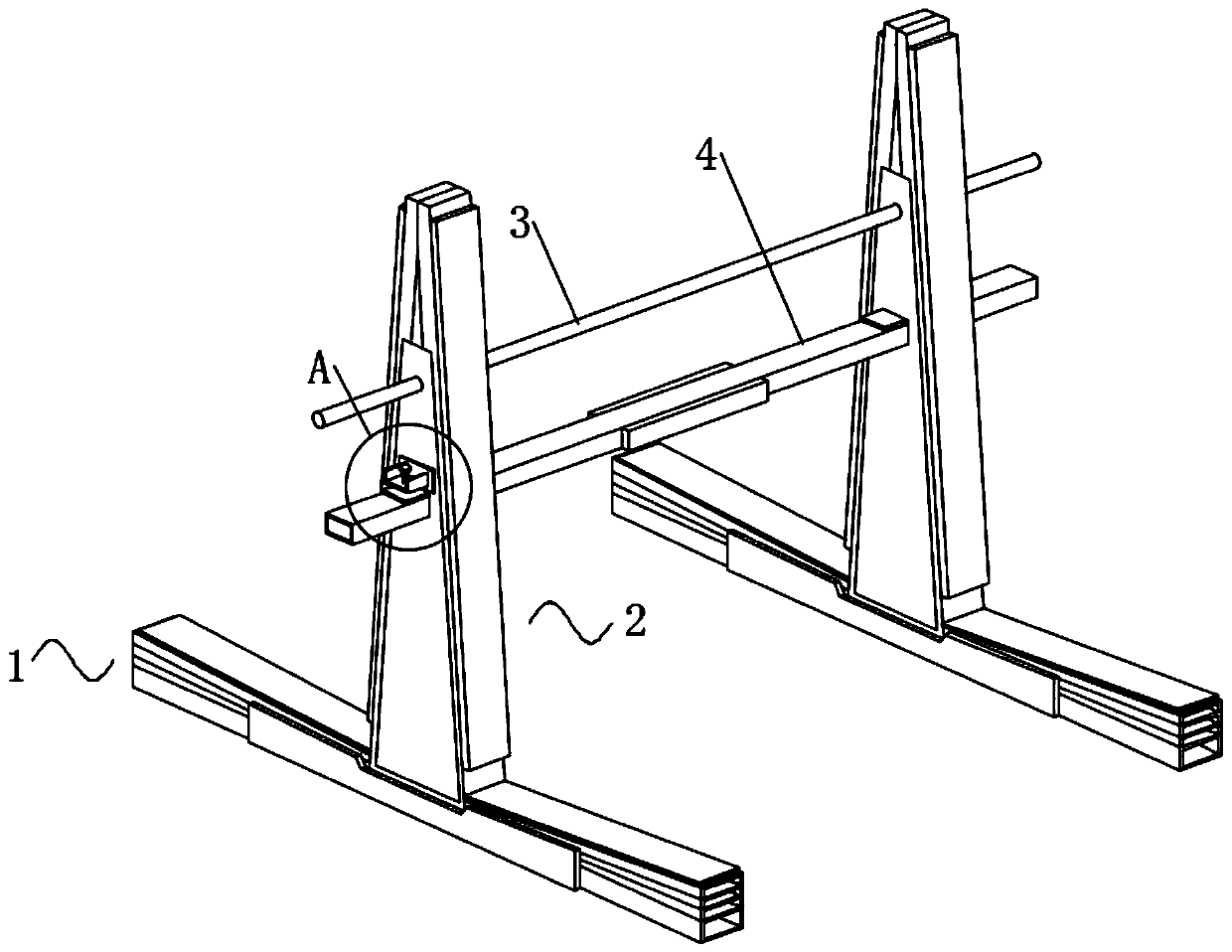

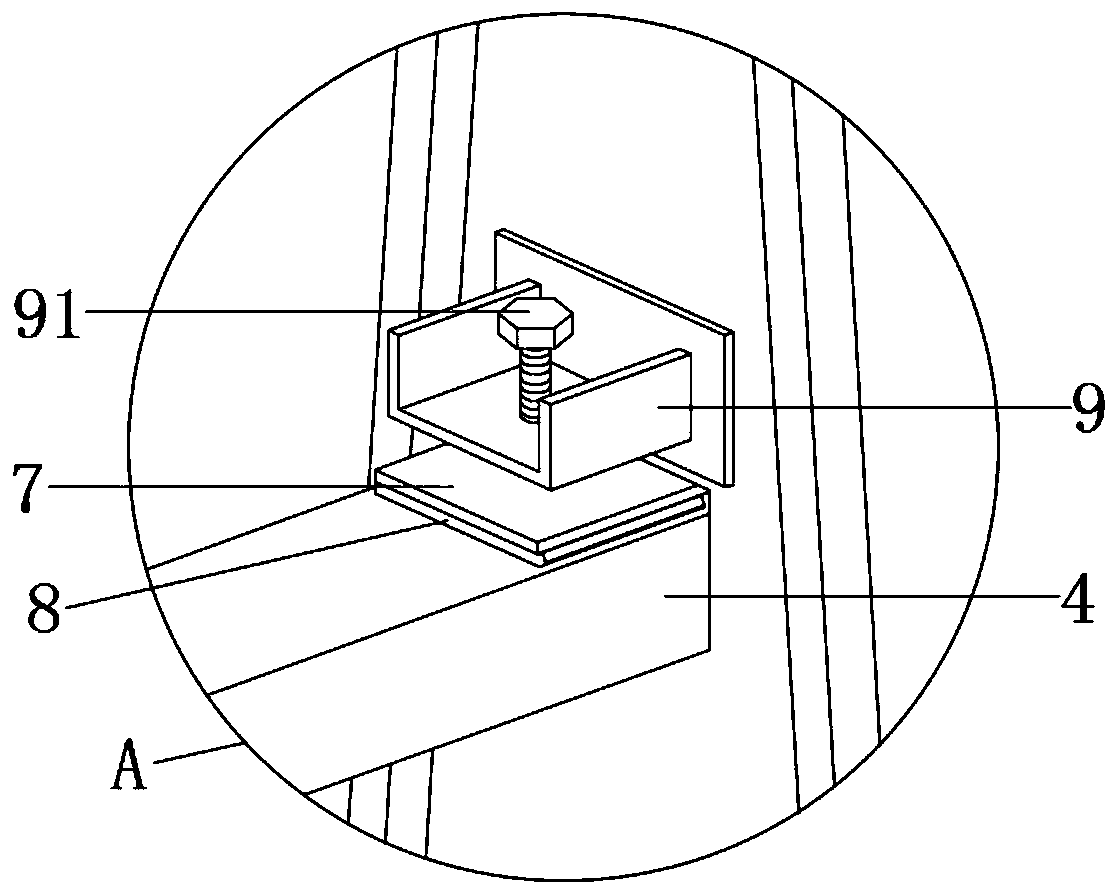

[0020] Example: see figure 1 , a combined flat glass transport frame, including a bottom plate 1 for supporting glass and a frame body 2 vertically welded on the bottom plate 1 in an A-shape, and two frames 2 arranged opposite to each other are horizontally connected to each other. The frame body 2 is arranged in parallel and has a stable upper beam 3 and a lower beam 4 . Wherein, the upper crossbeam 3 and the lower crossbeam 4 have specifications of different lengths, which run through between the two first reinforced steel plates 23 in the transverse direction, and the distance between the two frame bodies 2 can be adjusted according to the length of the plate glass and the upper crossbeam 3 of an appropriate length can be selected. and lower beam 4.

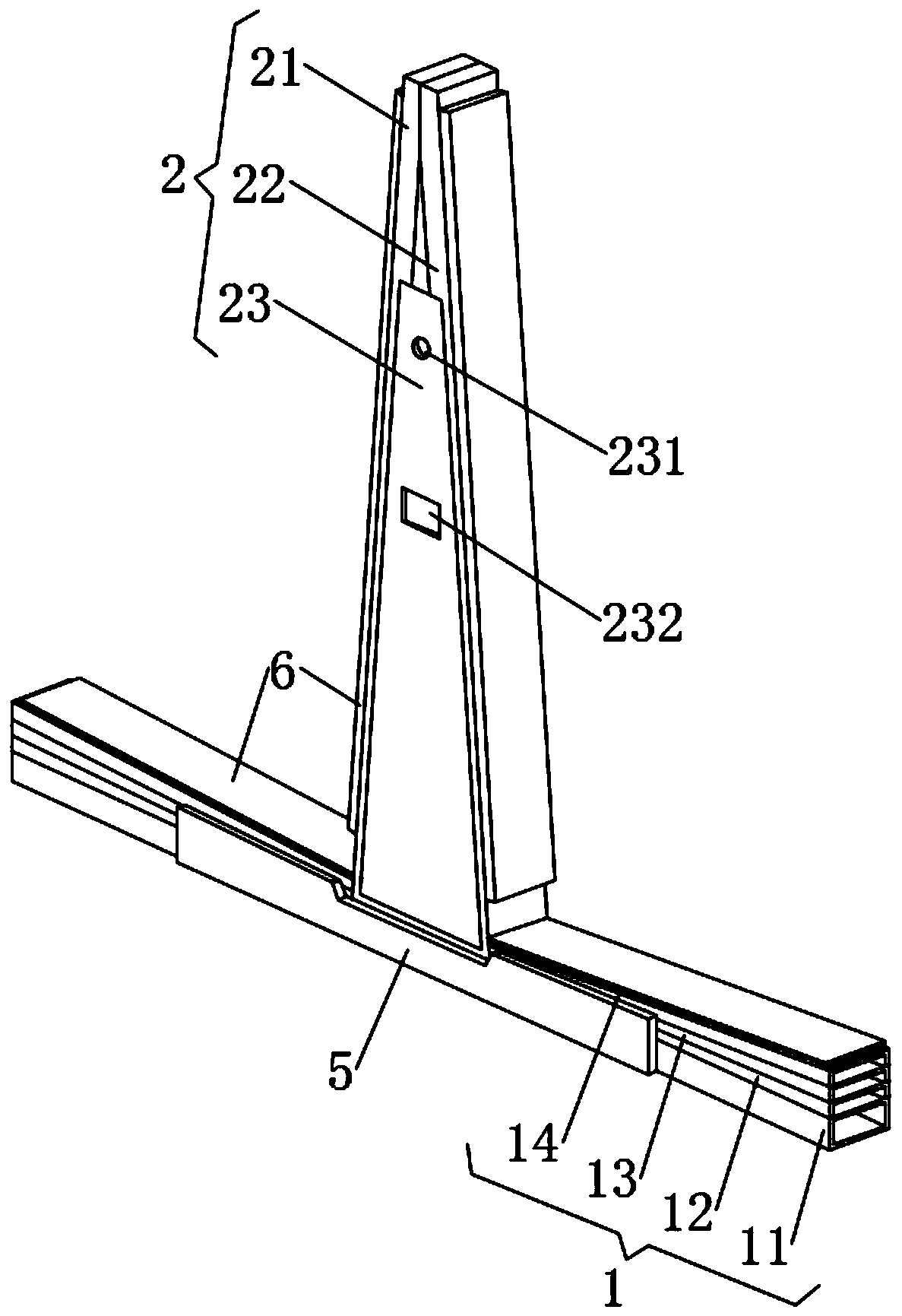

[0021] see figure 2 The frame body 2 includes two outwardly inclined, symmetrically distributed first side panels 21 and second side panels 22, the tops of the first side panels 21 and the second side panels 22 are attached...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com