Floating head type heat exchanger pipe bundle shell side pressure test tool

A floating-head heat exchanger and shell-side technology, which is applied to the sealing of the engine, engine components, mechanical equipment, etc., can solve the problems of many accessories, high use cost, and inability to interchange, so as to achieve easy installation and use, and strengthen the Strong versatility and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

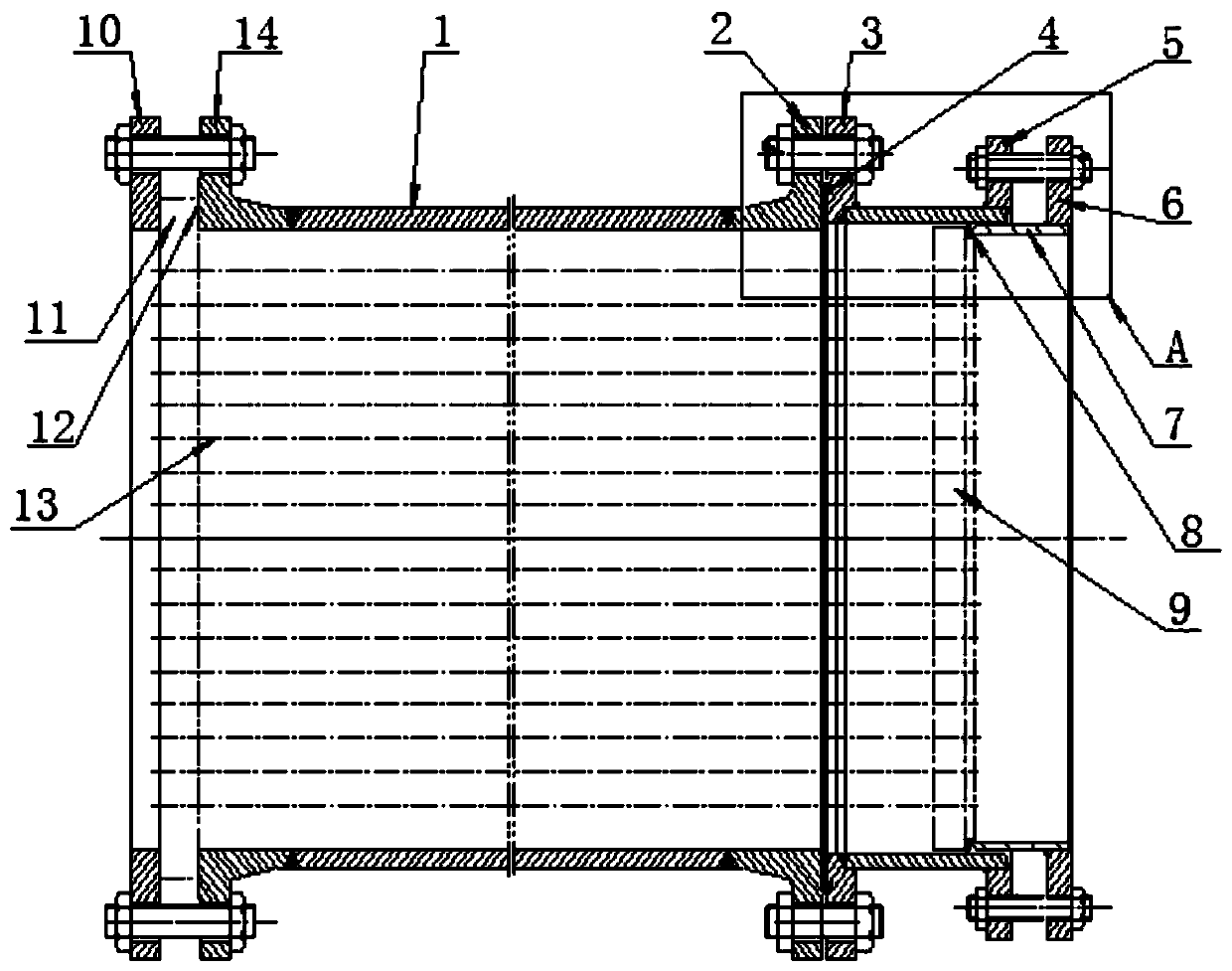

[0024] A floating head heat exchanger tube bundle shell side pressure test tool, including packing culvert, packing pressure ring and O-shaped rubber sealing ring;

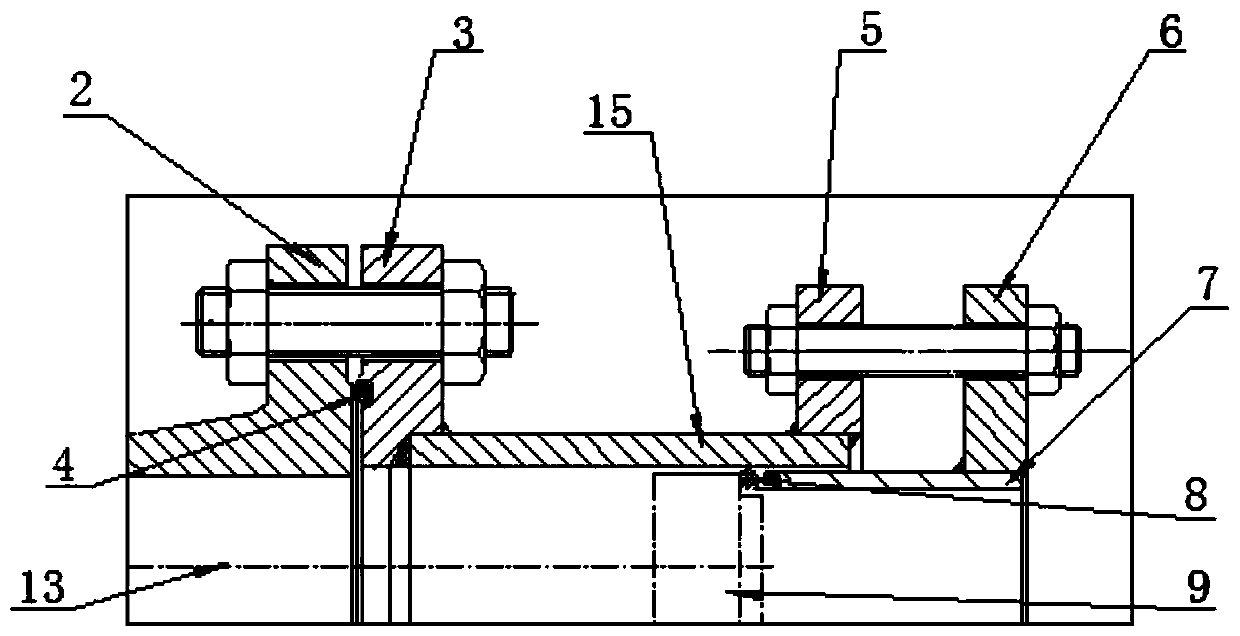

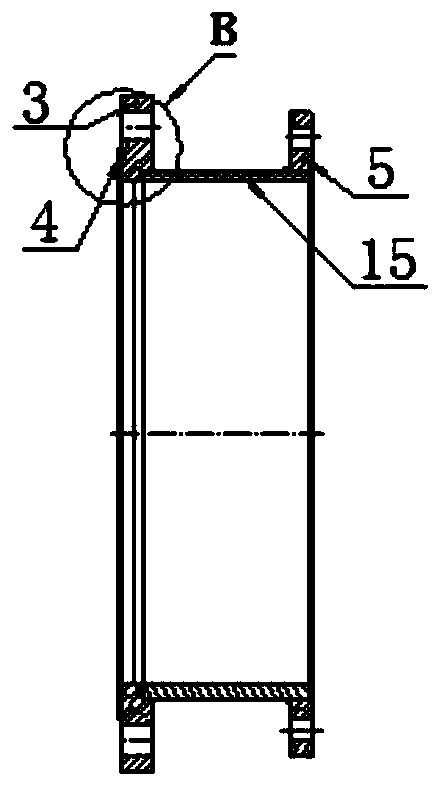

[0025] One side of the packing culvert is sealed and connected with the outer head cover side flange of the floating head heat exchanger. The movable tube plate 9 is arranged in the packing culvert barrel section 15 of the packing culvert. The packing follower includes the packing follower barrel section 7, and the packing follower One end of the barrel section 7 located in the packing culvert barrel section 15 abuts against the sealing surface of the movable tube sheet 9, and the other end of the packing ring barrel section 7 is connected with the packing culvert.

[0026] The two ends of the packing culvert section 15 are respectively provided with a first packing culvert flange 3 and a s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com