Pneumatic control detecting system for rivets

A detection system and rivet technology, applied in the field of automobile manufacturing, can solve the problems of reduced accuracy, inability to use the detection system, false detection, etc., and achieve the effect of reducing the detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

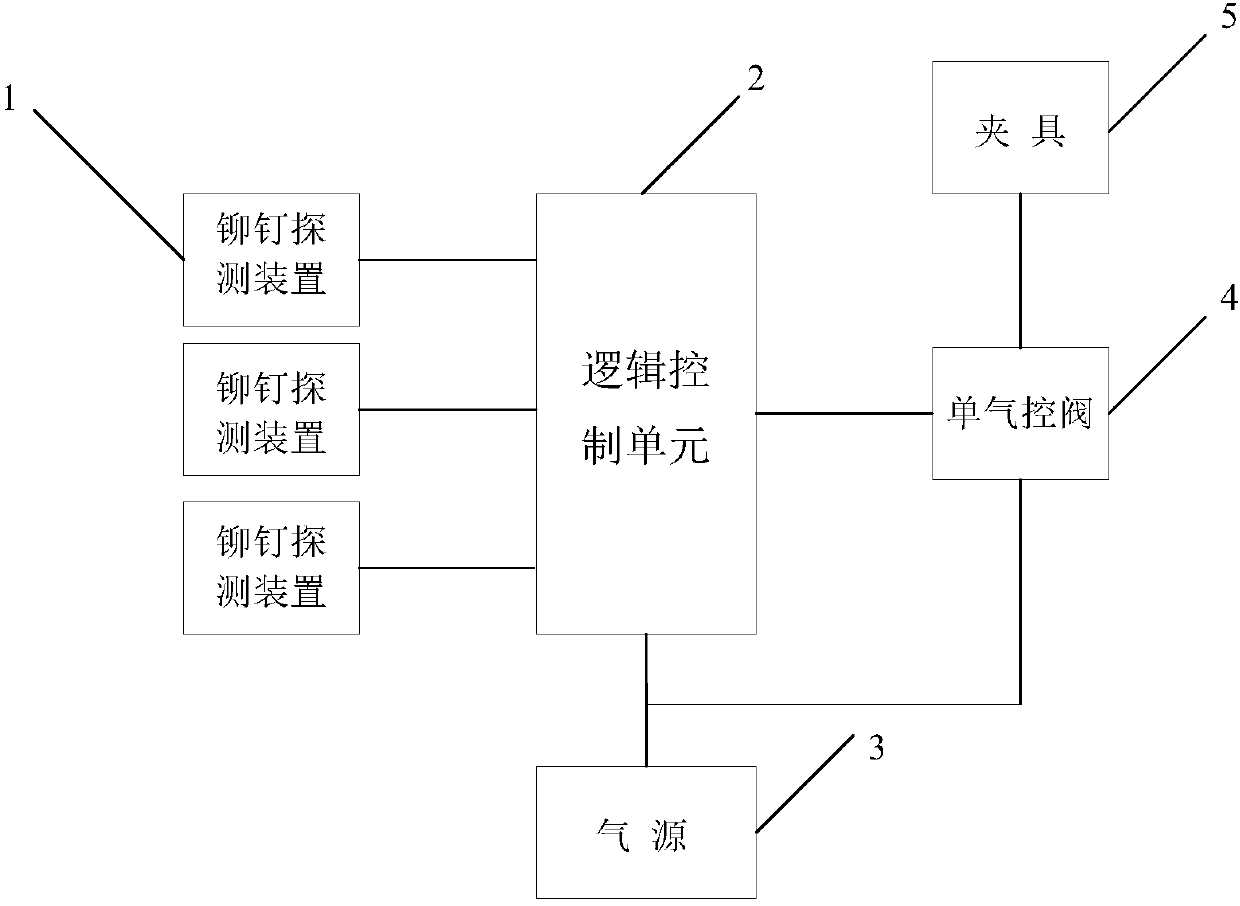

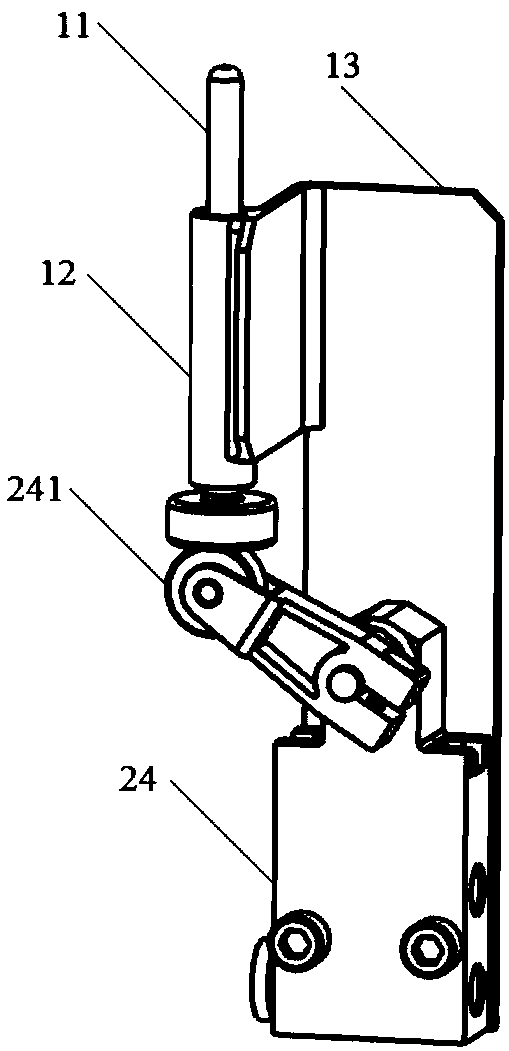

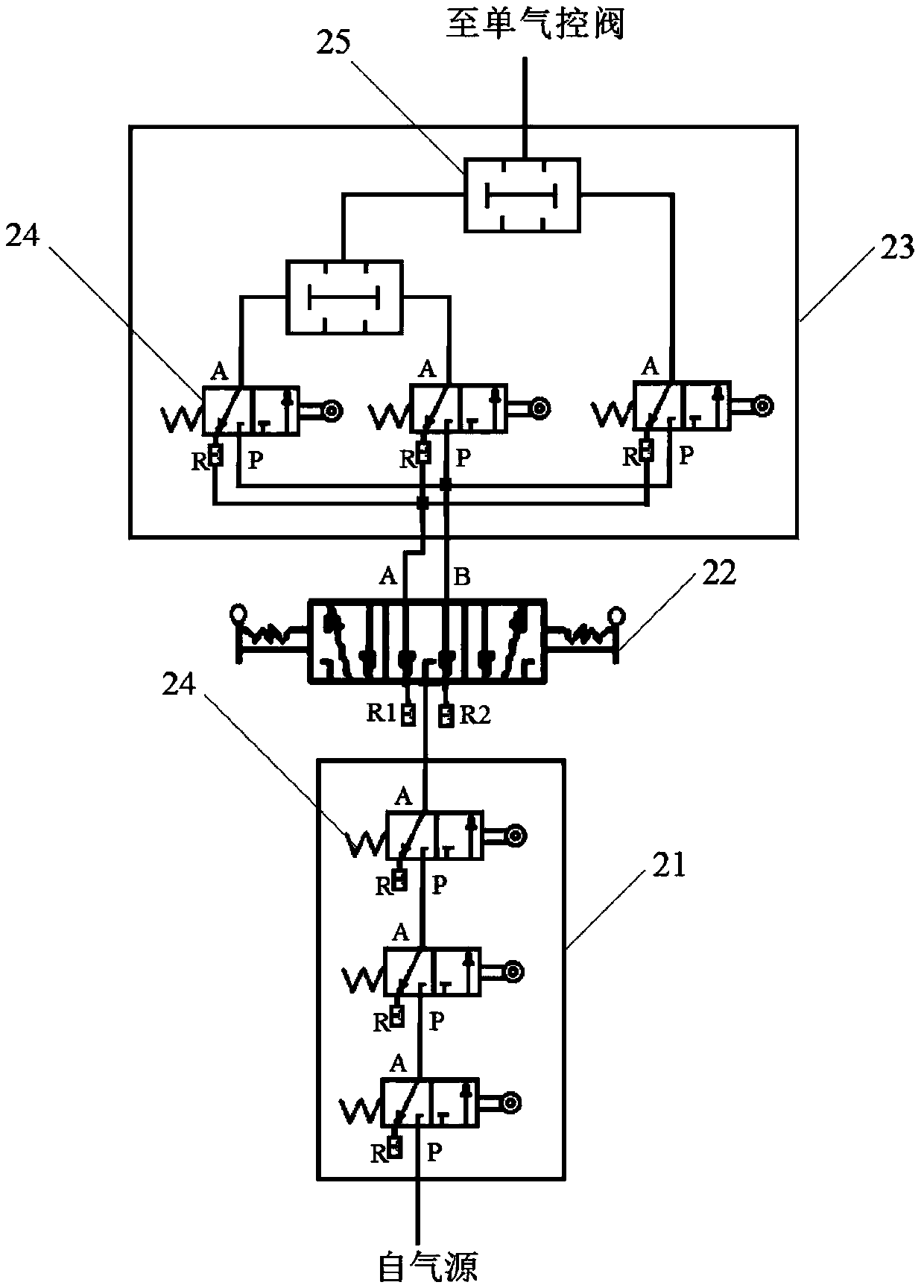

[0019] The structure of a rivet air control detection system in the embodiment of the present invention is as follows: figure 1 As shown, the system includes: a rivet detection device 1 that is in contact with the rivet or the inner plate at the position to be detected, a logic control unit 2 mainly composed of a pneumatic travel switch 24, and a single air valve that connects the air outlet to the main air inlet of the fixture 5. The control valve 4 is connected to the air source 3 connected to the air inlet of the single air control valve 4 , the input end of the logic control unit 2 is connected to the air source 3 , and the output end of the logic control unit 2 is connected to the pilot port of the single air control valve 4 . A rivet detection device 1 is in contact with a swing rod 241 of a pneumatic travel switch 24 of the logic control unit 2, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com