Novel storage battery housing

A battery and shell technology, applied in the field of new battery shells, can solve the problems of no shock absorption capacity, simple structure, no heat dissipation, etc., to increase or decrease the clamping range, improve safety and stability, improve The effect of anti-collision performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

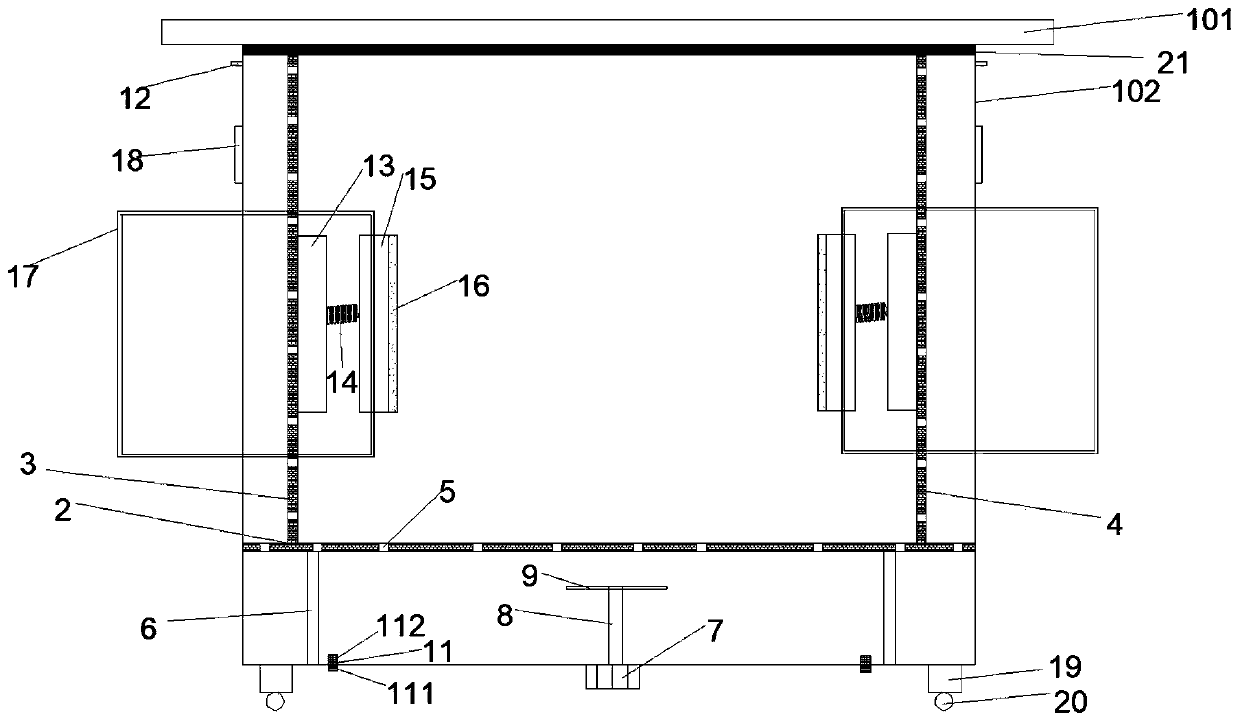

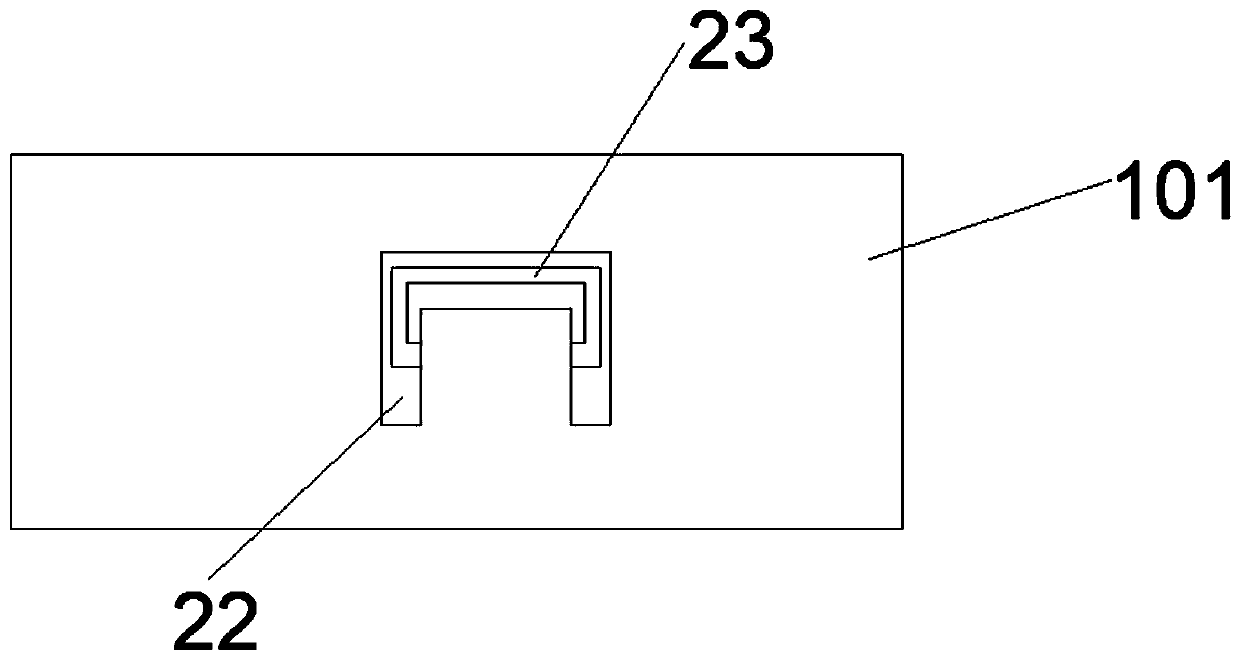

[0030] Such as Figure 1-Figure 6As shown, a new type of storage battery casing includes a casing 102, the top of the casing 102 is provided with a top cover 101, the top cover 101 and the casing 102 are movably connected by hinges, and the upper surface of the top cover 101 is provided with a U The U-shaped groove 22 is provided with a handle 23, which is convenient for the opening and closing of the top cover 101; the inner wall of the lower surface of the housing 102 is fixedly connected with the first baffle 2, and the first A second baffle 3 and a third baffle 4 are vertically arranged on the upper surface of the baffle 2 against the left and right inner walls of the housing 102, and the first baffle 2, the second baffle 3, and the third baffle 4 are all set through. There are several diversion holes 5, and the design of the diversion holes 5 increases the air circulation in the housing 102, which helps to accelerate the heat dissipation of the battery; the lower surface ...

Embodiment 2

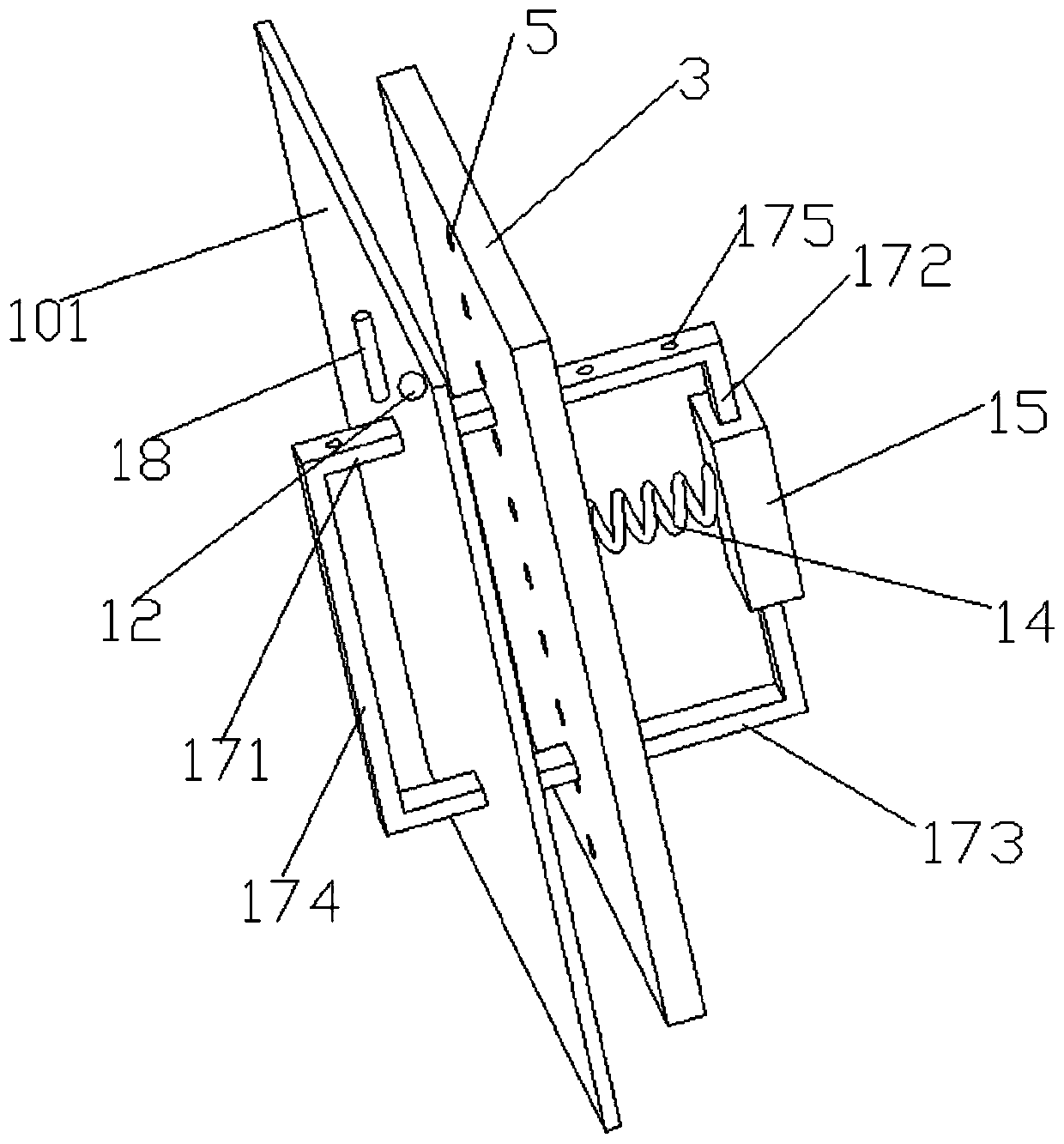

[0032] Such as Figure 1-Figure 6 As shown, this embodiment is a further optimization made on the basis of Embodiment 1. Specifically, the clamping device is provided with pull rods 17, and the pull rods 17 include a first pull rod 171 and a second pull rod 172. , the third pull rod 173, the fourth pull rod 174, the pull rod 17 is an integrated rectangle, the second pull rod 172 vertically runs through the upper and lower side walls of the fixing plate, the fourth pull rod 174 is located outside the housing 102, the first pull rod 171 A number of fixing holes 175 are equidistantly arranged on the top, and the first pull rod 171 and the third pull rod 173 pass through the baffle plate and the side wall of the housing 102 and extend to the outside of the housing 102; the upper end of the pull rod slides on the side wall of the housing 102 A first push rod 18 is provided, and the first push rod 18 matches with the fixing hole 175 on the first pull rod 171 .

[0033] In this embo...

Embodiment 3

[0035] Such as Figure 1-Figure 6 As shown, this embodiment is further optimized on the basis of Embodiment 2. Specifically, the outer wall of the bottom of the housing 102 is provided with a support seat 19, and the lower end of the support seat 19 is fixedly connected with a pulley 20. Brake pads are arranged on the pulley 20 .

[0036] In this embodiment, the support seat 19 and the pulley 20 are provided to facilitate the movement of the present invention, and the operation is convenient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com