Ice skate blade bending apparatus

A bending and skating technology, used in skates, skating parts, sports accessories, etc., can solve the problems of time-consuming removal and reassembly, and the design is not widely adopted, and achieves the effect of easy adjustment and easy transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

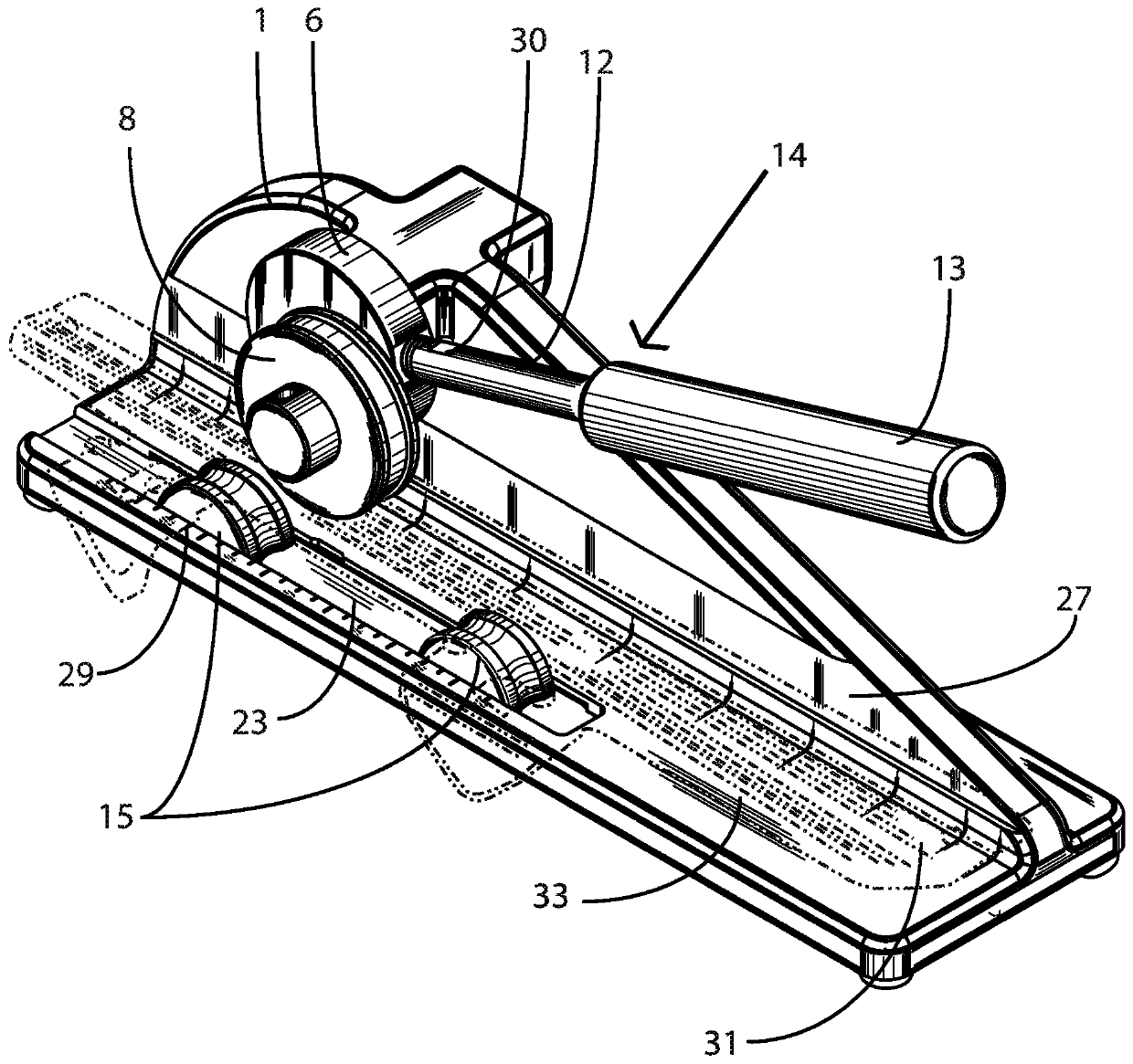

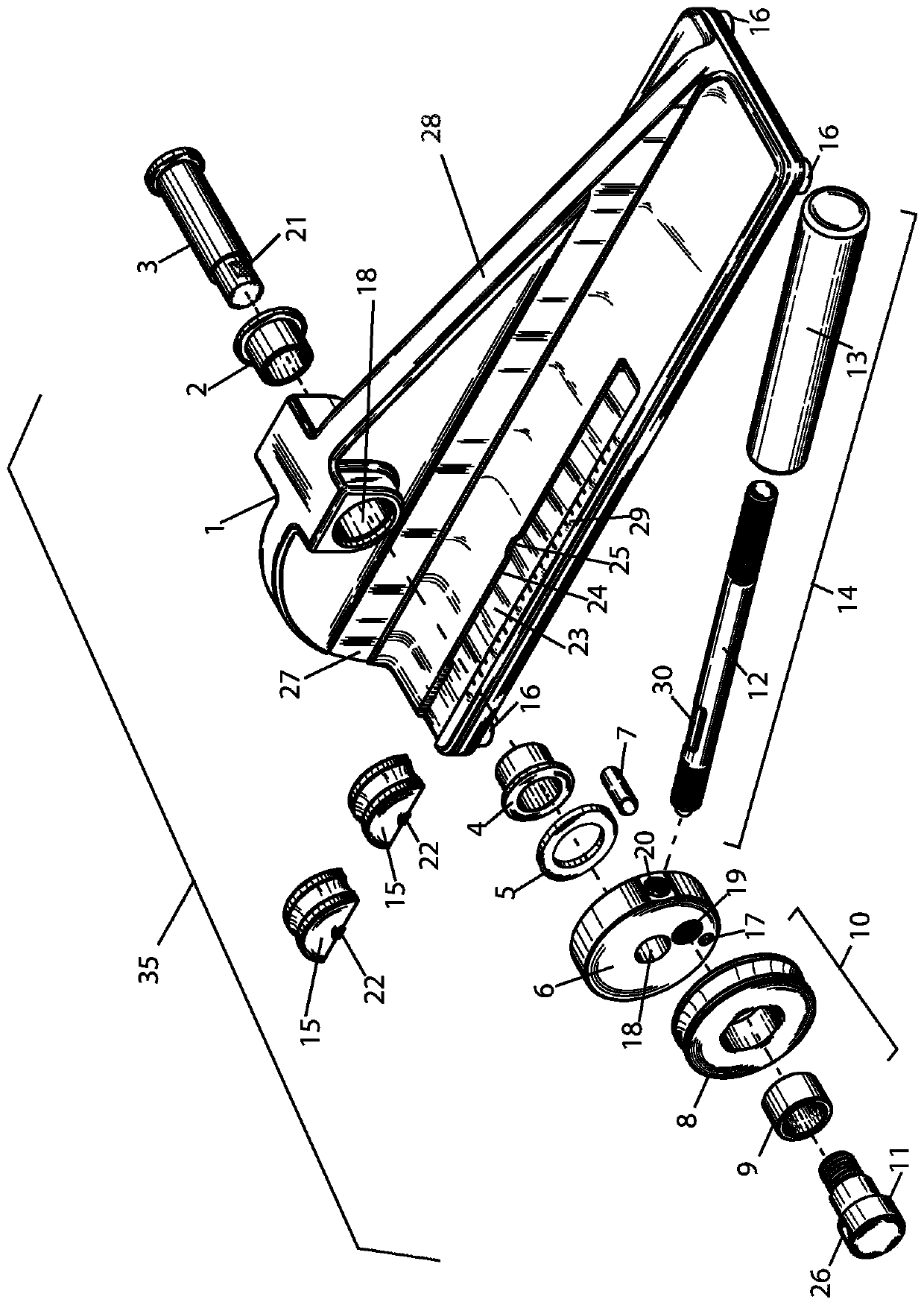

[0080] Referring now to the drawings, there is described a preferred embodiment of a skate blade bending apparatus. It should be noted that the articles "a", "an" and "the" as used in this specification include plural referents unless the content clearly dictates otherwise.

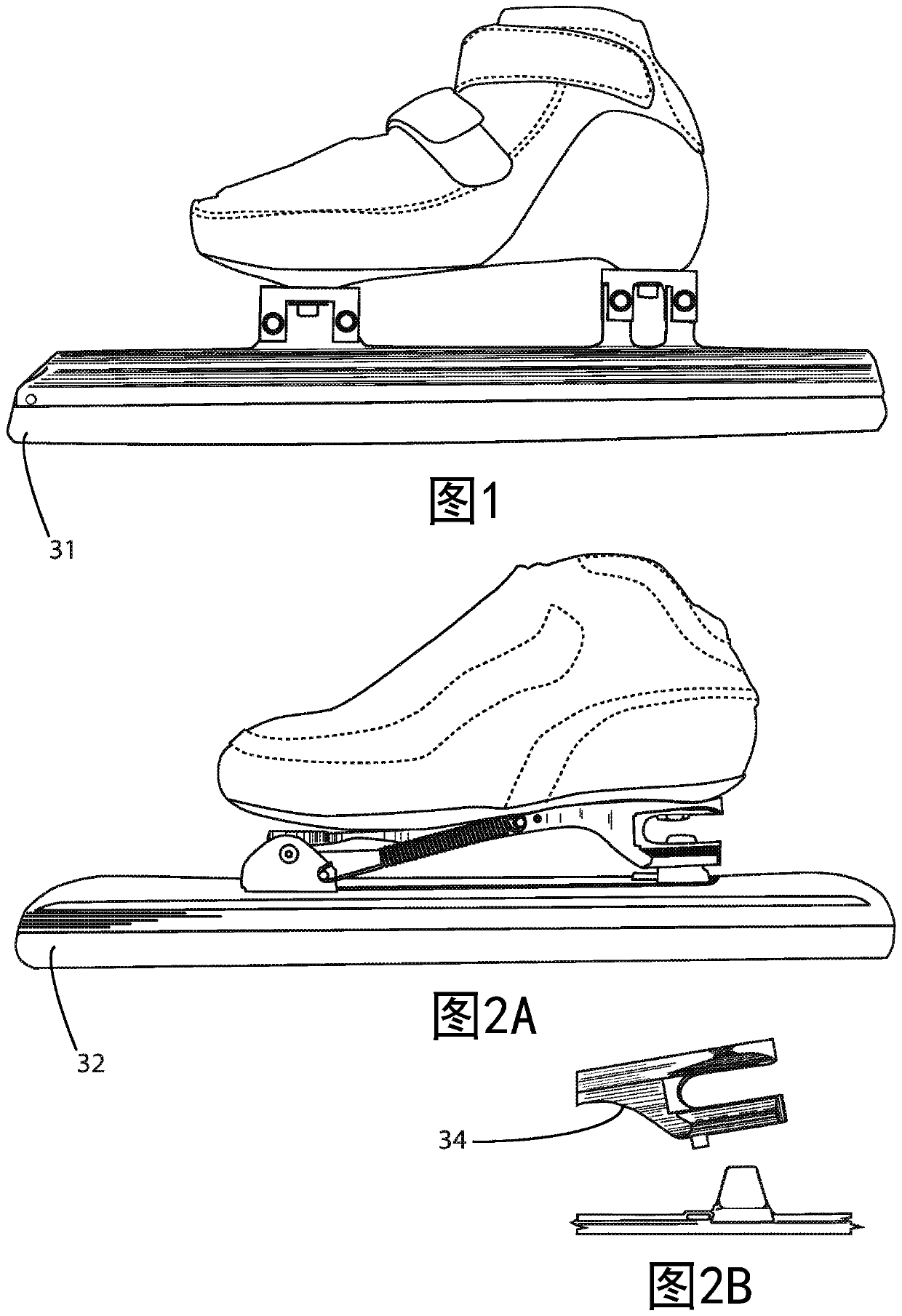

[0081] refer to image 3 and Figure 4 , showing a preferred exemplary embodiment of a blade bending device. The depicted bending apparatus can be used to bend short track skate blades (31) or long track skate blades (32), examples of which are shown in Figures 1 and 2A . Skate blades (31) and (32) are typically provided with an elongated rail-type support (33), which is generally cylindrical and tubular, has appendages to facilitate attachment of blade blade components and mounting points for securing boots, typically Called the skate tube. The blade tube usually has a slot adapted to hold and hold the upper portion of the blade or blade on one side of the blade tube and a mounting platform called a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com