Etching method for making chalcogenide memory elements

A chalcogenide, memory element technology, applied in the direction of electrical components, etc., can solve the problem of not providing the benefits of the invention, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

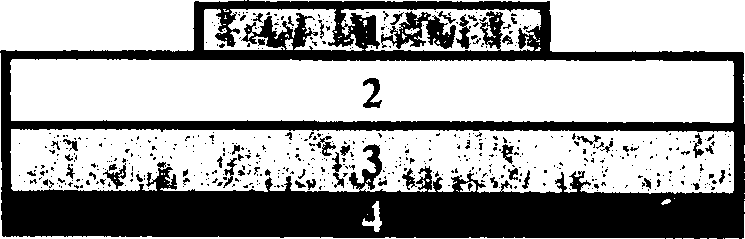

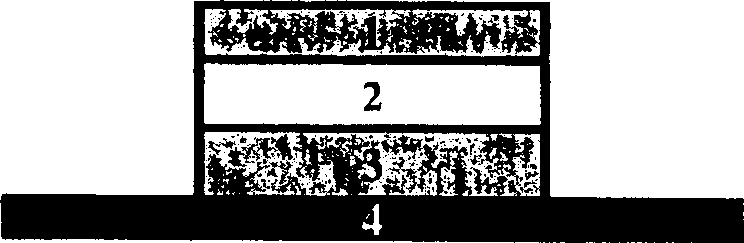

Method used

Image

Examples

Embodiment

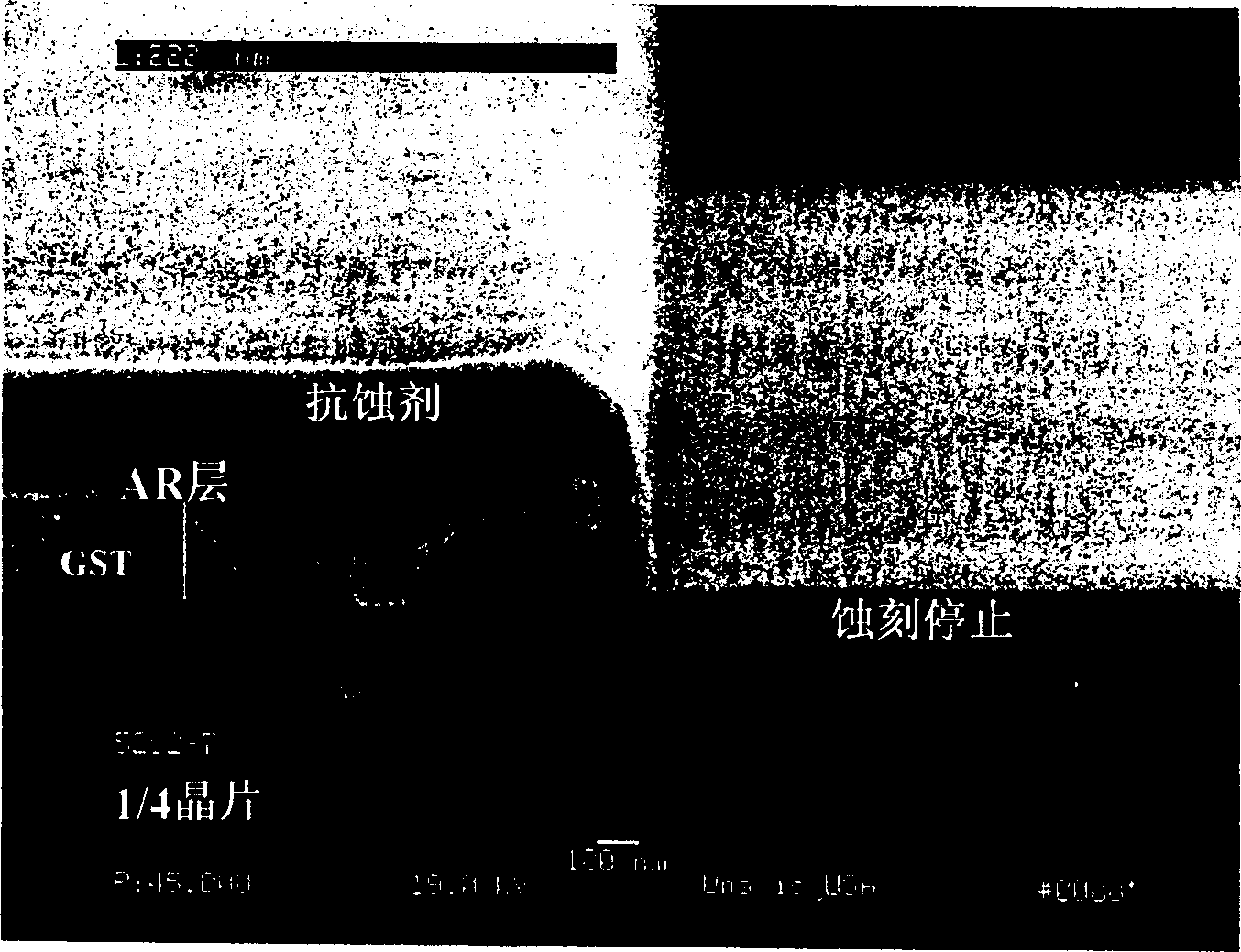

[0035] System specification

[0036] Initial experiments were performed on a commercial Unaxis SLR 770 etcher. The reactor used a 2MHz ICP source to generate a high density plasma. The ion energy at the substrate (wafer) was controlled by independently biasing the cathodes at 13.56 MHz. The wafer temperature was regulated by mechanically clamping the wafer to a liquid-cooled cathode combined with He backside cooling. End-of-process experiments used a commercial Unaxis Spectraworks Optical Emission System (OES).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com