A wear-resistant gearbox

A gearbox and wear-resistant technology, applied in the field of gearboxes, can solve the problems of small variation range of engine torque, reduced gearbox service life, mixed ferromagnetic debris, etc., to improve the effect of iron scrap removal, reduce wear, reduce Loss reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

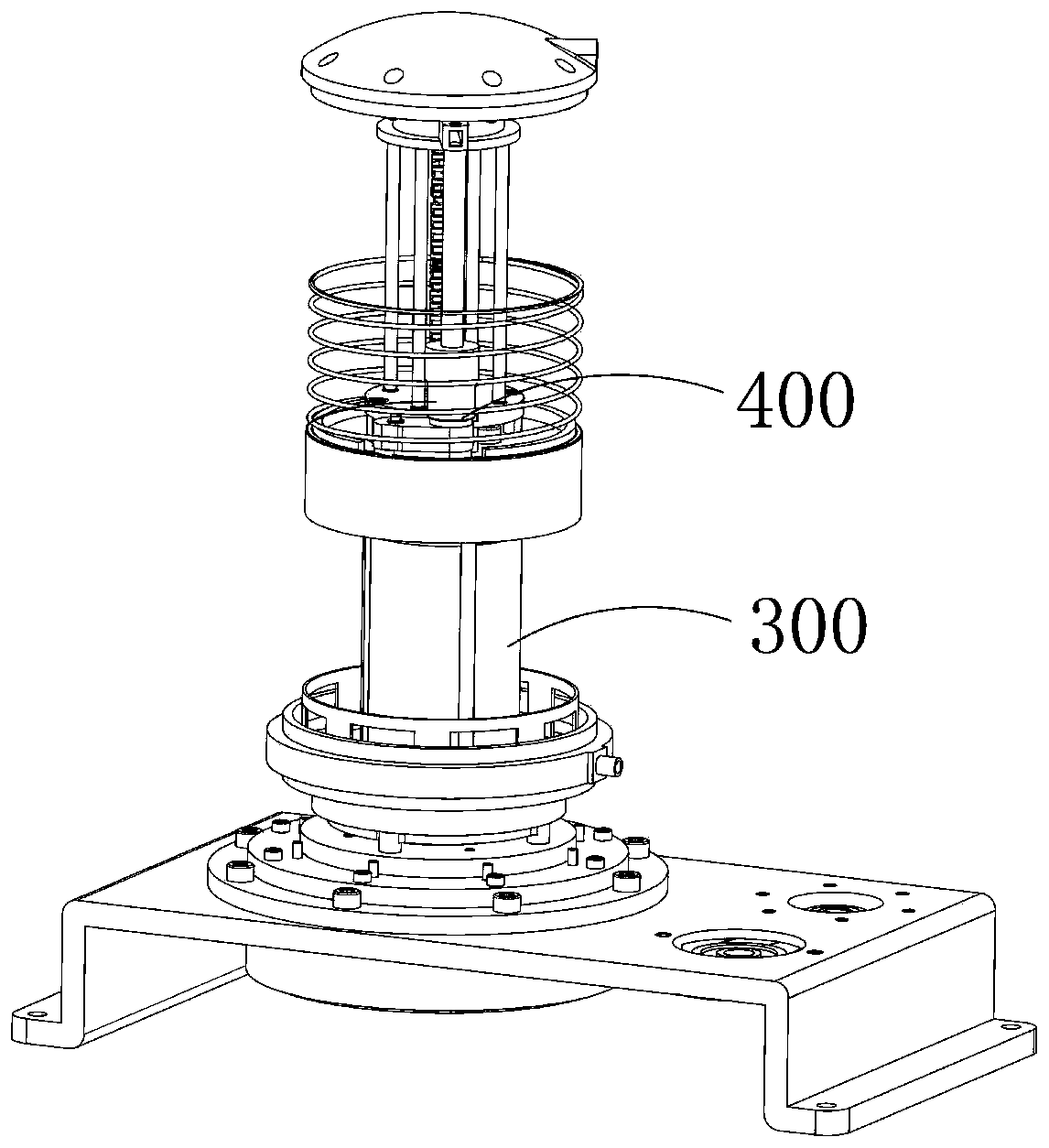

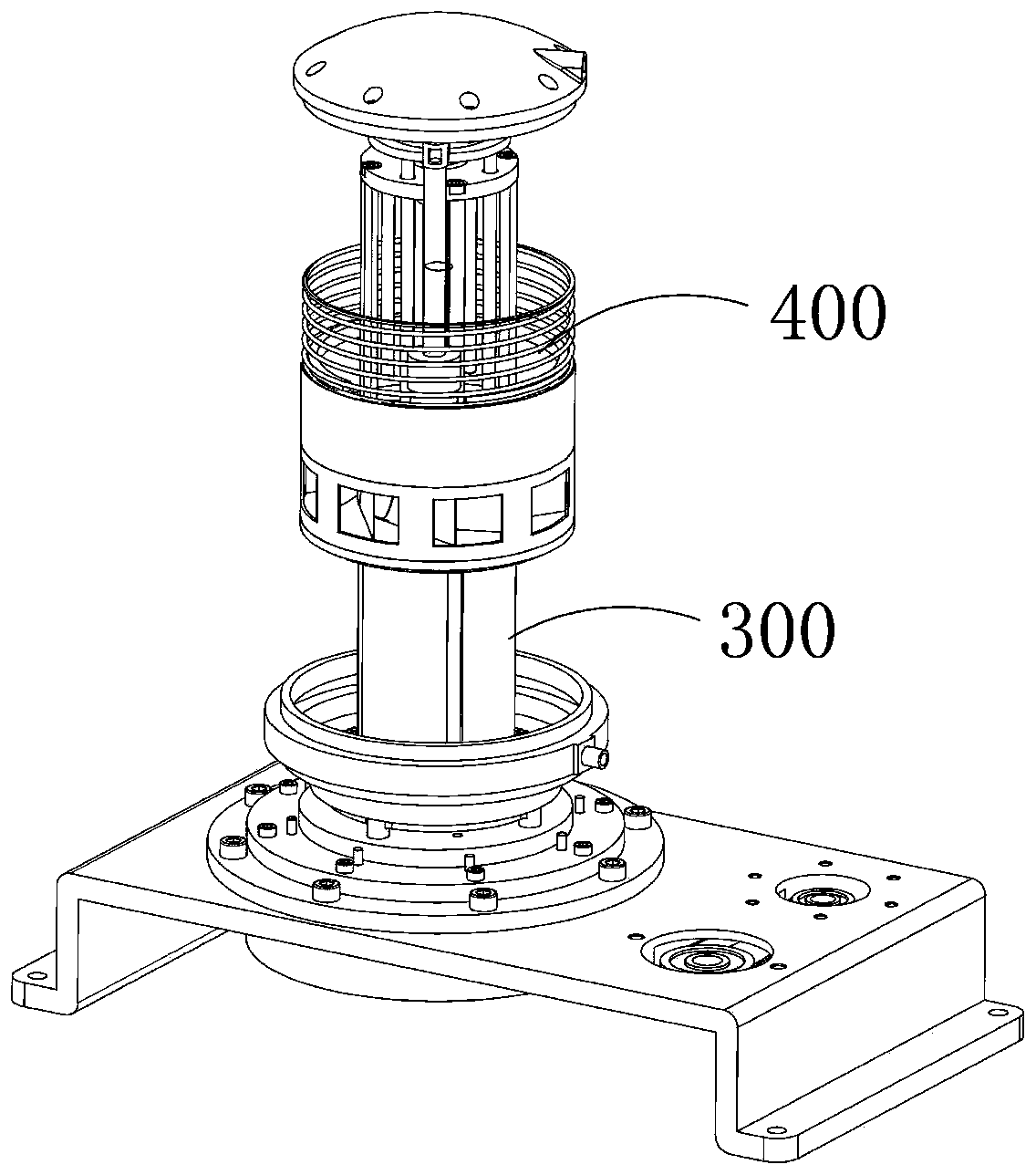

[0065] The present invention adopts the magnetic adsorption method to separate the ferromagnetic debris from the gearbox oil. The service life of the gearbox is improved. In the process of removing iron filings, the atomizing nozzle makes the oil enter the main casing in the form of atomization, which can greatly improve the effect of removing iron filings. In addition, the setting of the closed mechanism avoids the atomization state. The oil under the fan is sent to the chip storage casing, which greatly reduces the loss of oil in the process of separation and purification.

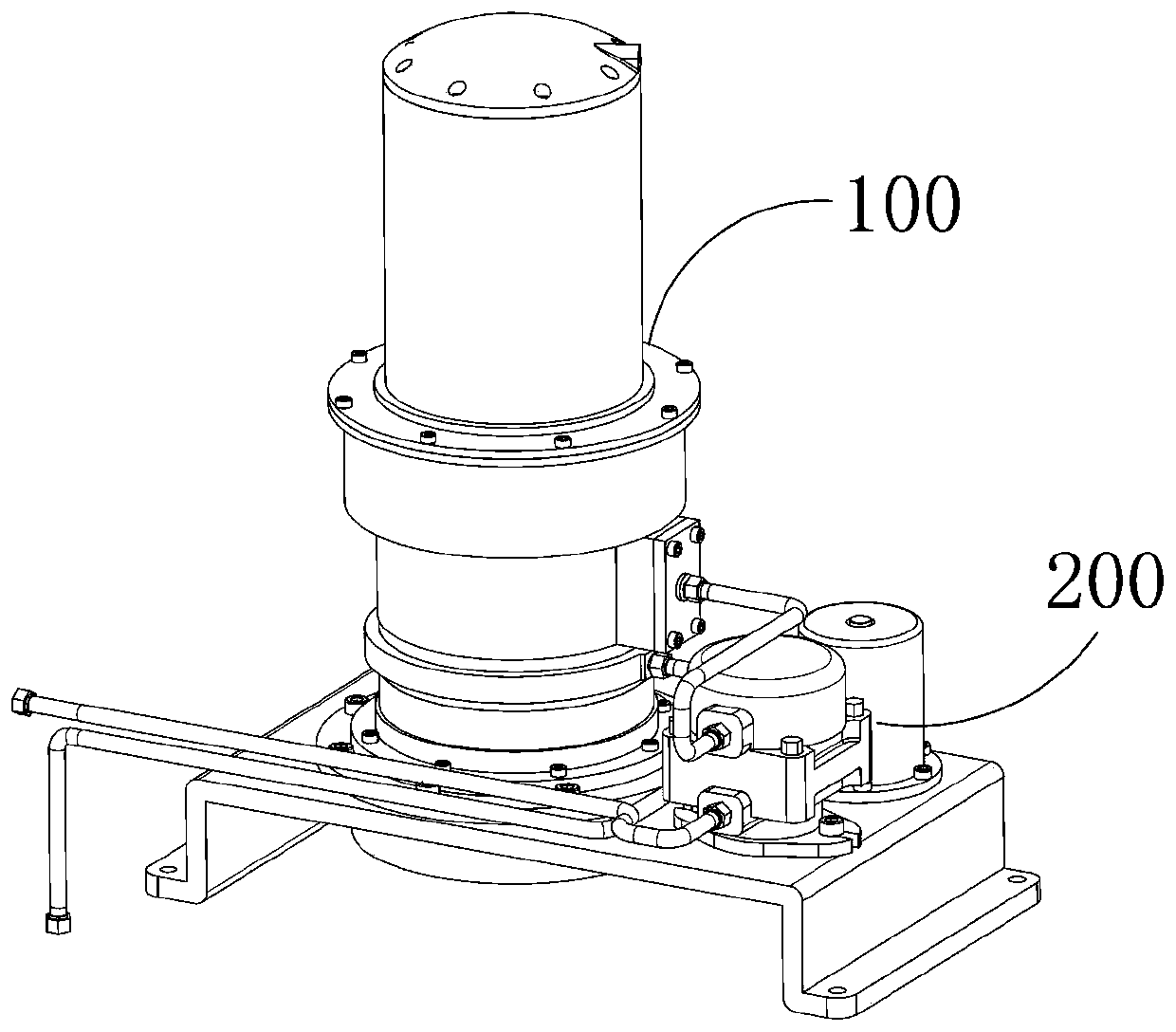

[0066] A wear-resistant gearbox includes a base, an installation casing 100, a transition device 200, a separation device 300, and a chip sweeping device 400. The base is arranged horizontally, and the installation casing 100 is installed on the base, and the separation device 200 is connected to the sweeping chip. The devices 400 are all arranged inside the installation housing 100 , the transition devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com