Control method for improving wear resistance of gearbox

A control method and gearbox technology, which is applied in the field of gearboxes, can solve the problems of small variation range of engine torque, reduce the service life of gearboxes, and mixed ferromagnetic debris, so as to improve the effect of iron filings removal, reduce wear, and reduce The effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

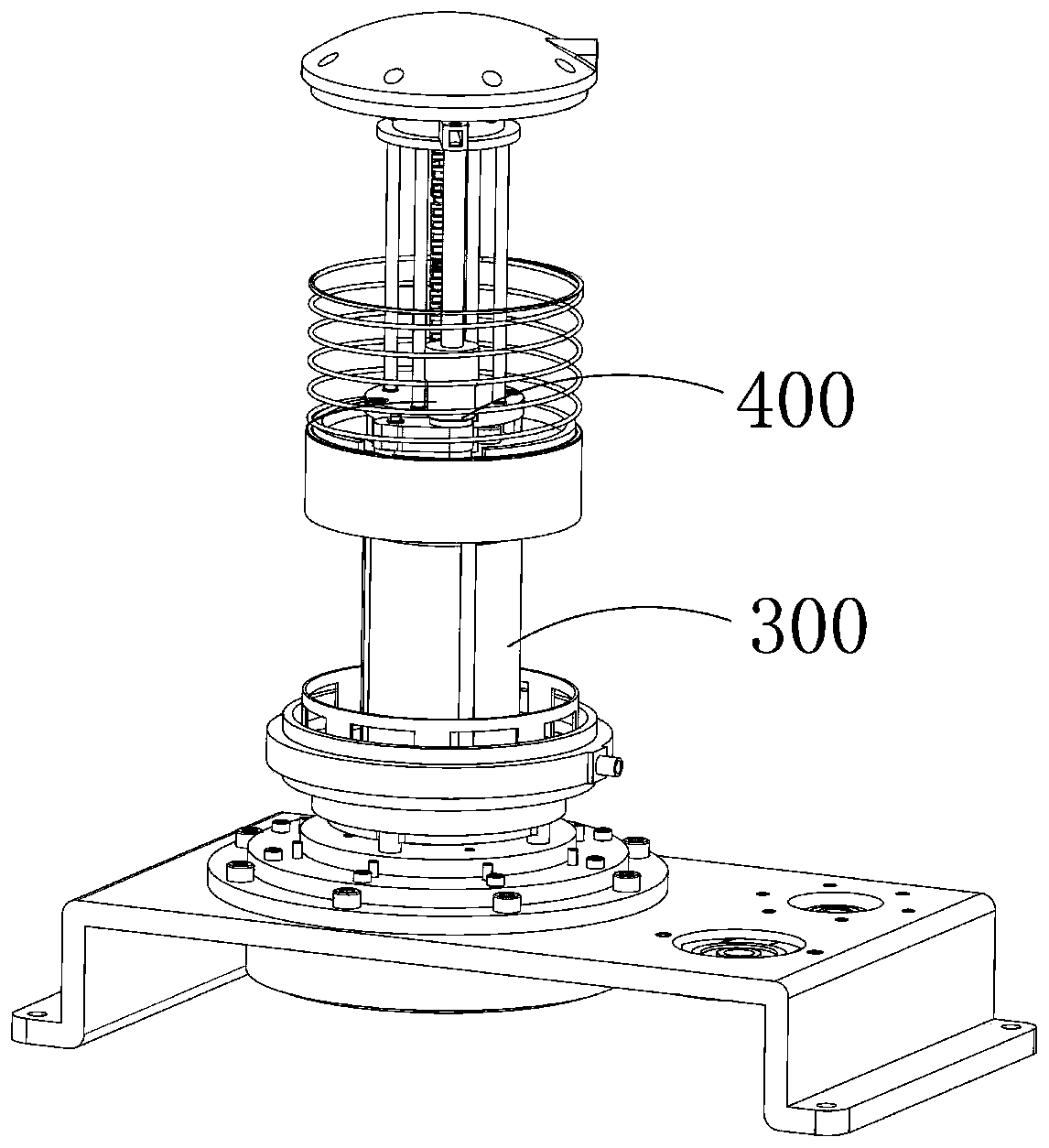

[0072] The control method for improving the wear resistance of the gearbox comprises the following steps:

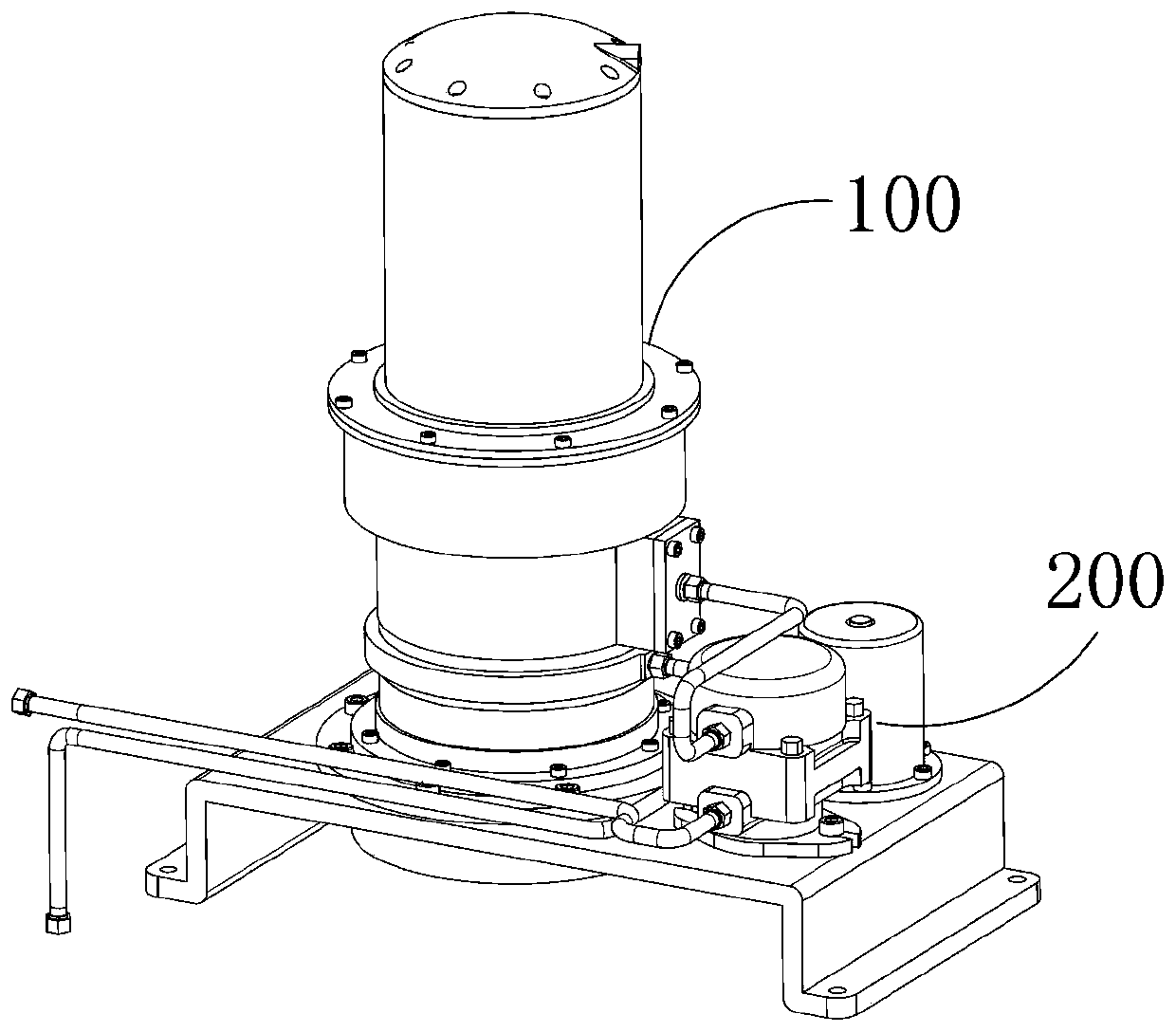

[0073] S1: the transition device 200 installed on the base sucks the gearbox oil into the installation housing 100;

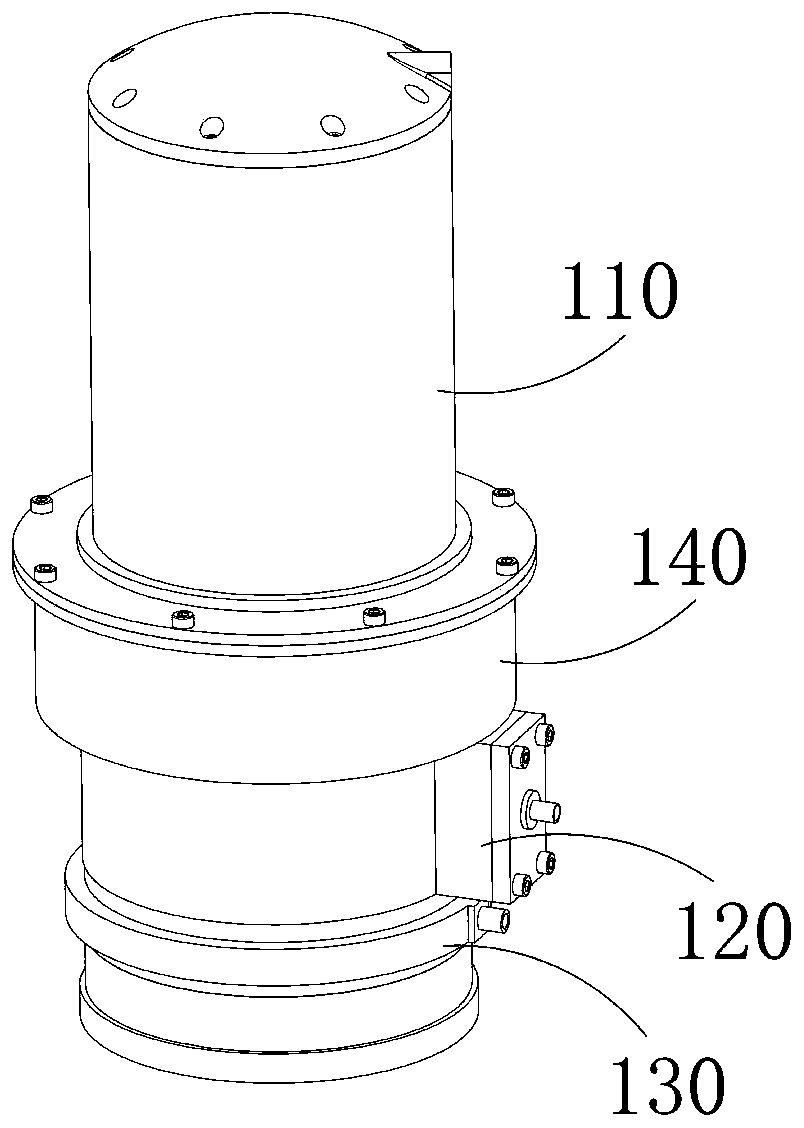

[0074] The installation housing 100 includes a main housing 110. The main housing 110 is a circular cylindrical structure with two ends open and arranged vertically. The outer circular surface of the main housing 110 is sequentially provided with chip outlets from top to bottom. Port 113, oil inlet 111, and oil outlet 112. The outside of the main housing 100 is also provided with a debris storage shell 140, an oil inlet shell 120, and an oil outlet shell 130 in sequence from top to bottom. The oil inlet nozzle 121 connected to the oil port 111 is connected to the oil outlet shell 130. The oil outlet nozzle connected to the oil outlet 112 is arranged on the oil outlet shell 130. The connection between the oil inlet nozzle 121 and the oil inlet 111 is also ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com