Manufacturing method and grooving mechanism of aluminum sheath for car air conditioner

A technology of an automobile air conditioner and a manufacturing method, which is applied in the field of manufacture of an aluminum sleeve for an automobile air conditioner and its slotting mechanism, can solve the problems of easy deformation of the aluminum column wall, difficult processing, narrow processing space, etc., and achieve high processing efficiency, Effect of preventing deformation and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

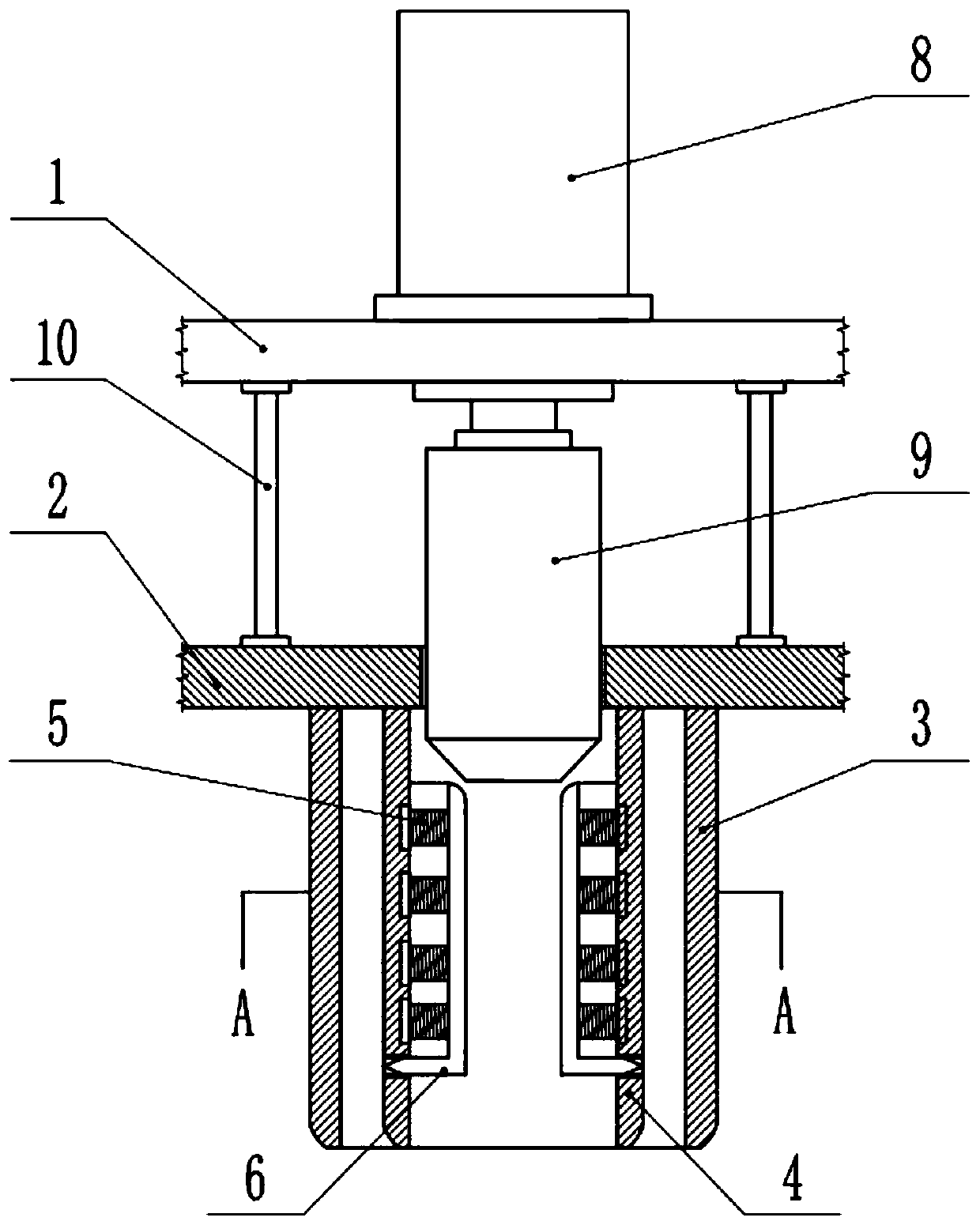

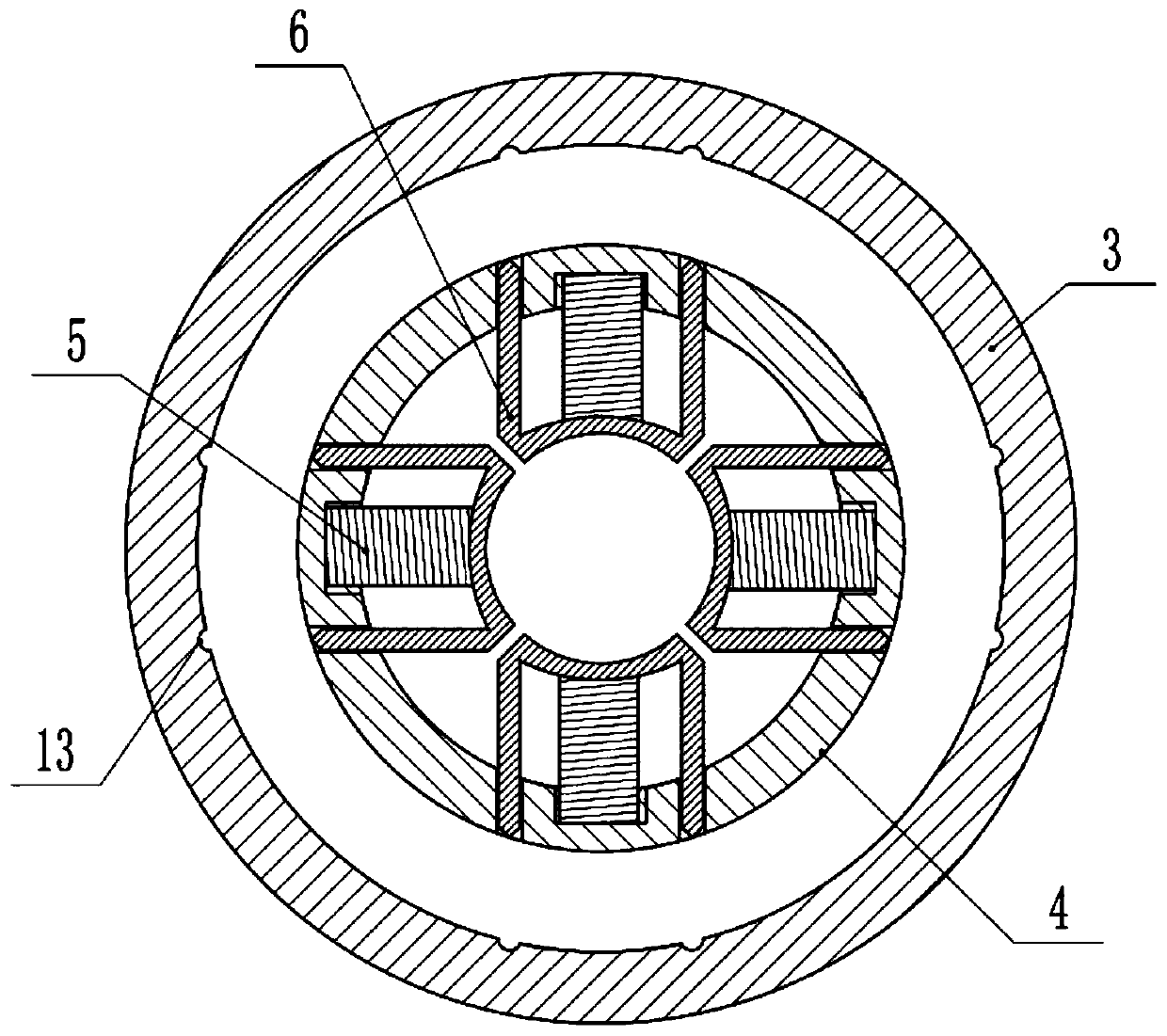

[0021] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

[0022] A method for manufacturing an aluminum sleeve for an automobile air conditioner, comprising the steps of:

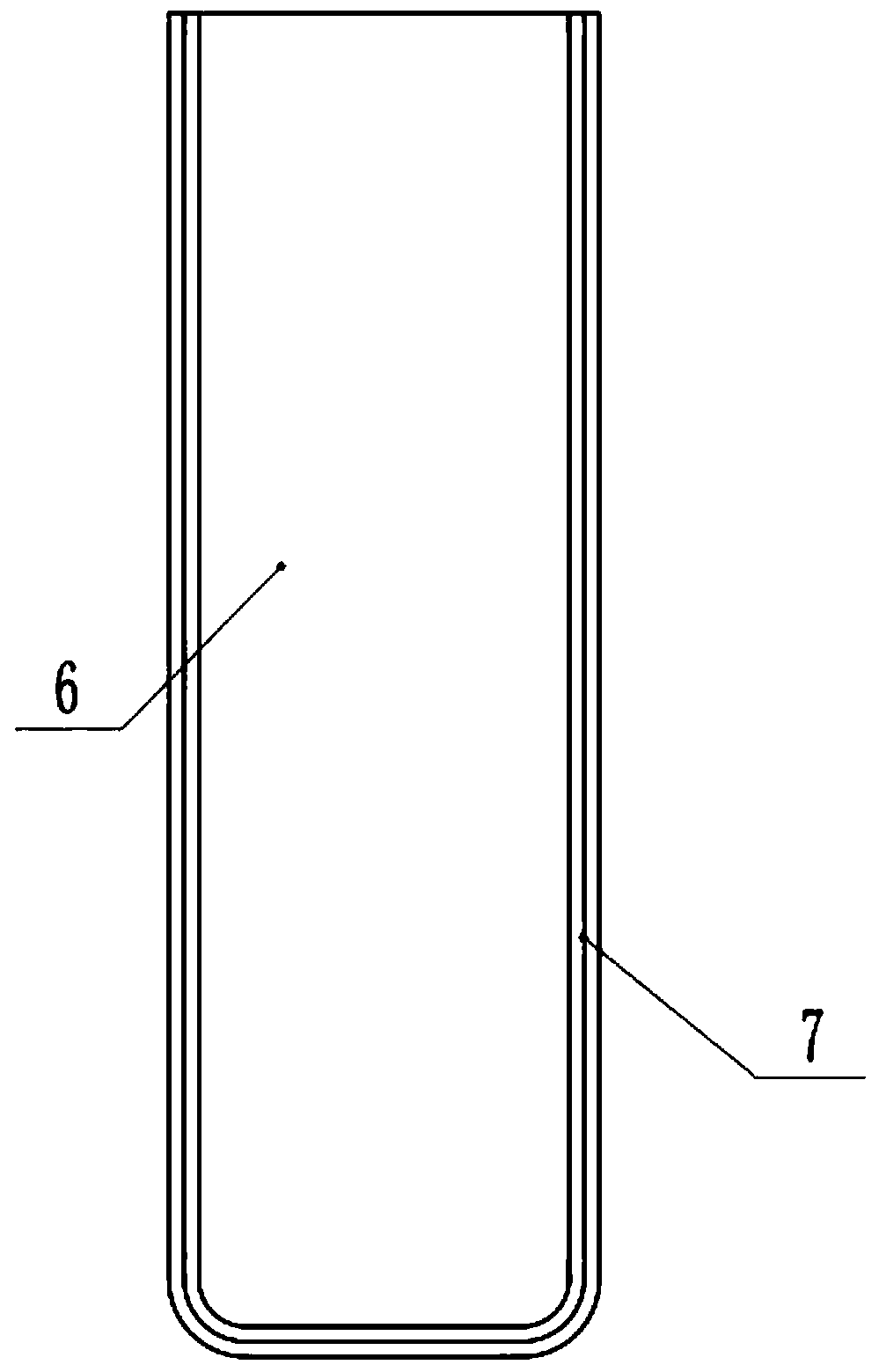

[0023] Step 1, cold extrusion forming to produce an aluminum sleeve blank with a hollow cylinder in the middle, and a gap is maintained between the outer wall of the hollow cylinder and the inner wall of the aluminum sleeve blank;

[0024] Step 2. Insert the aluminum sleeve blank produced in step 1 into the concave hole of the template with a concave hole, and put a ring between the aluminum sleeve blank and the hollow cylinder, and the ring is filled with the aluminum sleeve blank The gap between the piece and the hollow cylinder and its height is consistent with the height of the hollow cylinder;

[0025] Step 3: Insert a hollow grooving column with multiple telescopic blades into the h...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap