Finished #-shaped block stacking device

A well-shaped and finished product technology, which is applied to the stacking, transportation and packaging of objects, conveyor objects, etc., can solve the problems of unguaranteed stacking quality and low efficiency of manual stacking and stacking, so as to improve handling efficiency and ensure stacking quality , reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

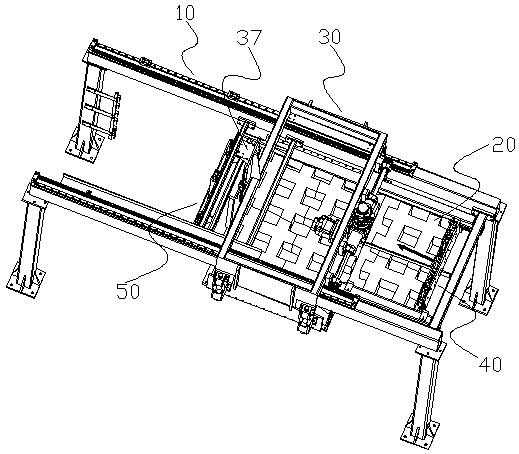

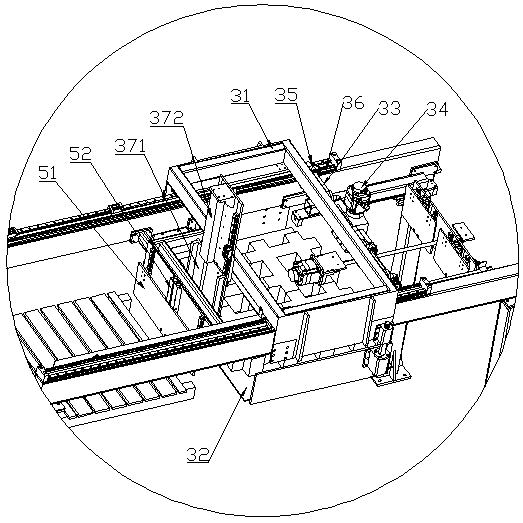

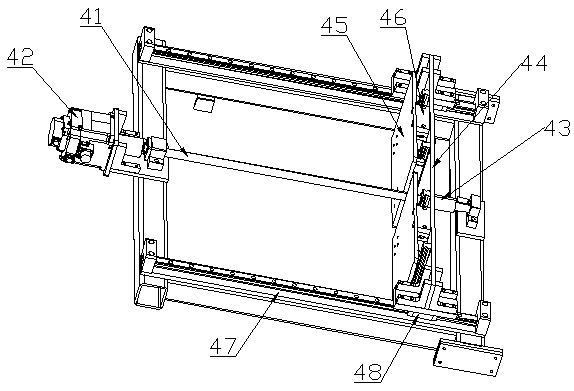

[0018] Such as figure 1 Shown, a kind of finished product well-shaped block palletizing device is used for finished product well-shaped block stacking output, comprises the frame 10 that is arranged on the finished product well-shaped block conveying device and the stacked well-shaped block conveying device, frame 10 Be provided with the lateral transfer device 30 of carrying finished well-shaped block 20; The frame 10 is also provided with a loading device 40, which is used to load the finished product tic-tac-toe block 20 output by the finished product well-shaped block conveying device to the lateral transfer device 30 On; the frame 10 is also provided with an unloading device 50, which is used to unload the finished well-shaped block 20 on the lateral transfer device to the stacked well-shaped block conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com