Installation structure and construction method of floors

A technology for installing structures and floors, which is applied to building structures, floors, buildings, etc. It can solve the problems affecting the flatness of the floor and the sinking of the floor boards, and achieve the effect of facilitating laying and construction and not being wasteful

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

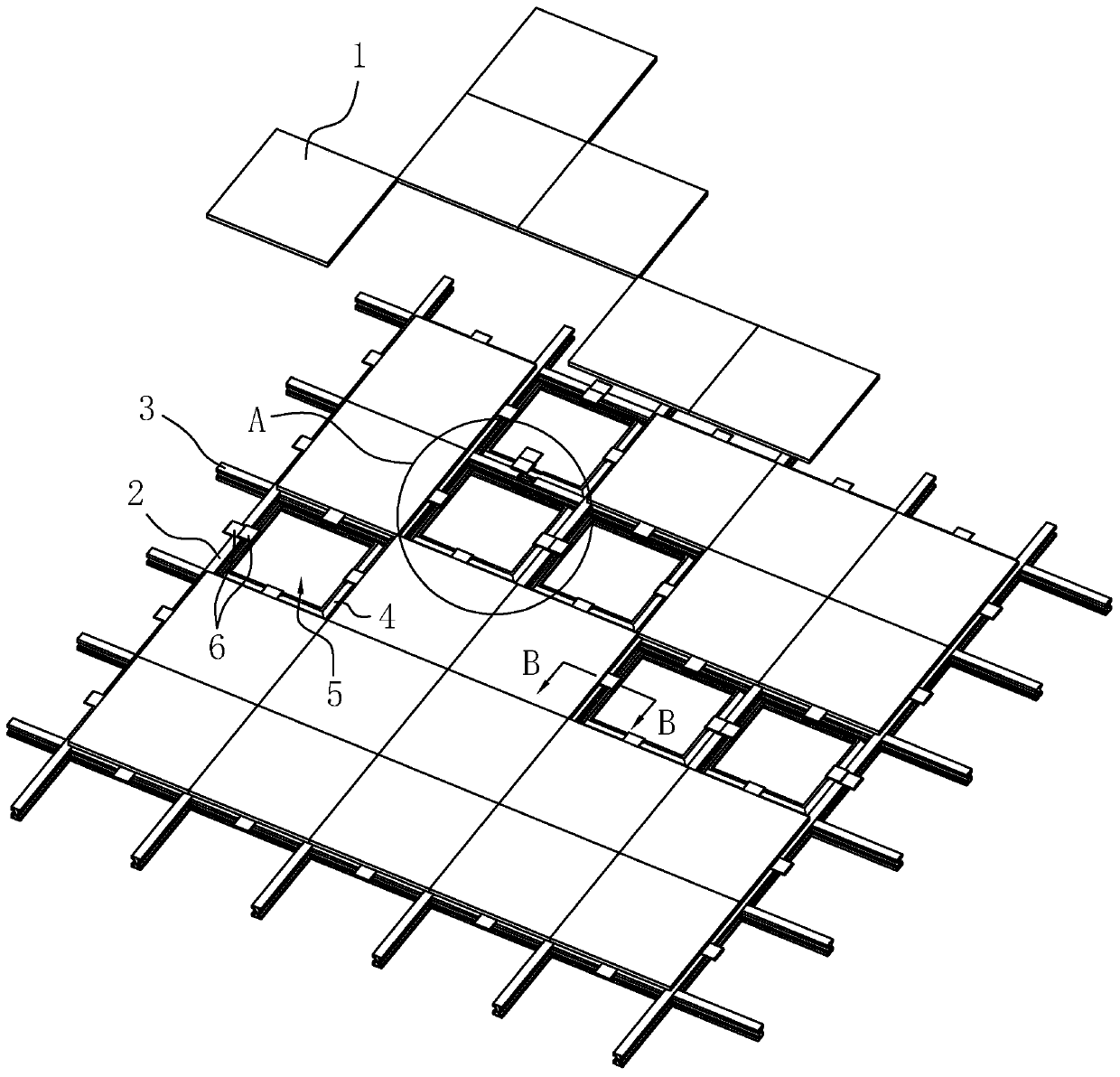

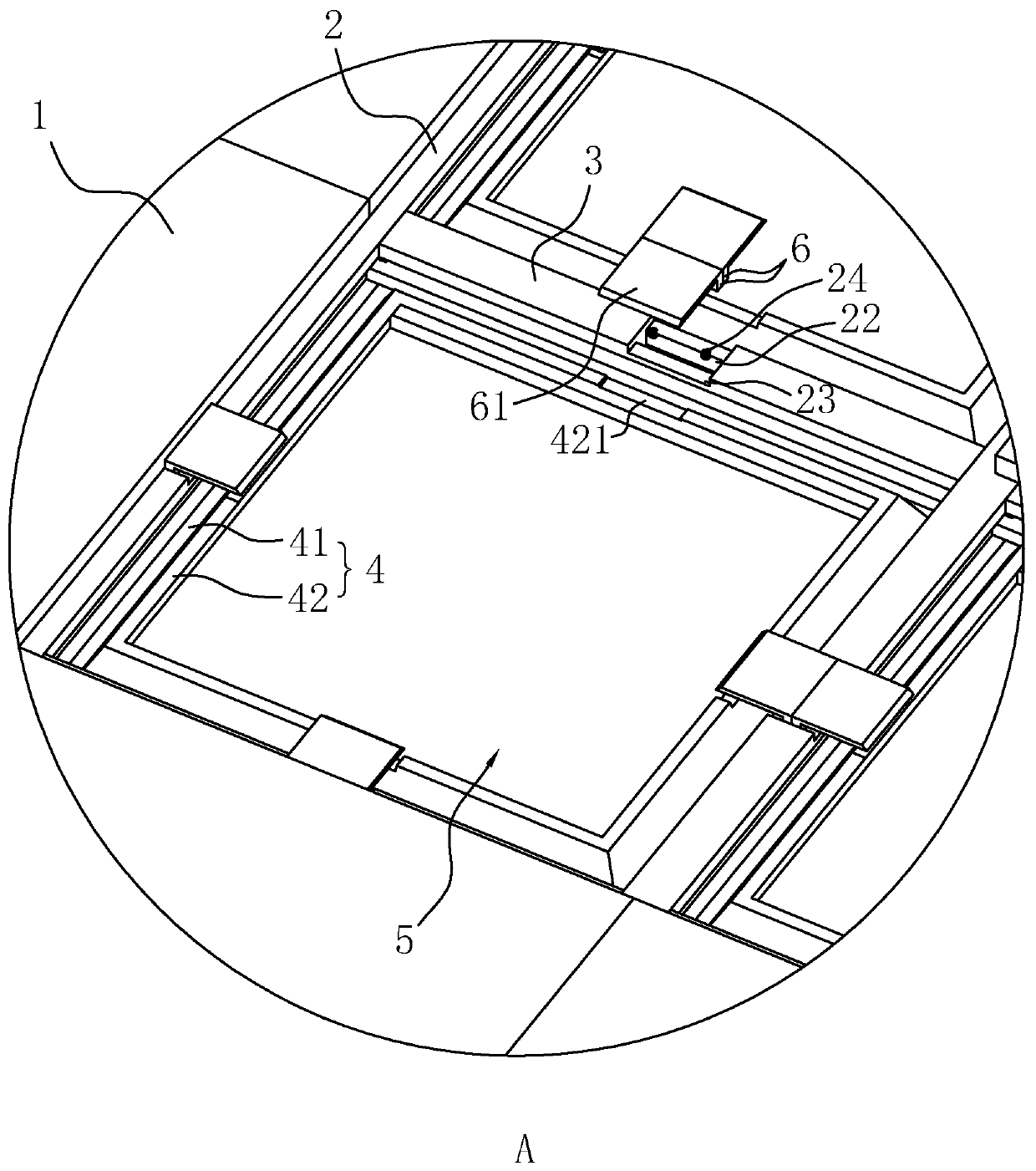

[0042] refer to figure 1 , is a floor installation structure disclosed in the present invention, comprising a floor board 1, a filling frame 4, a longitudinal keel 2 and a transverse keel 3 intersecting each other, and a rectangular installation cavity 5 is formed between the forward keel 2 and the transverse keel 3 , wherein the filling frames 4 are installed in the installation cavity 5 one by one, and the floor boards 1 are installed above the filling frames 4 in a one-to-one correspondence.

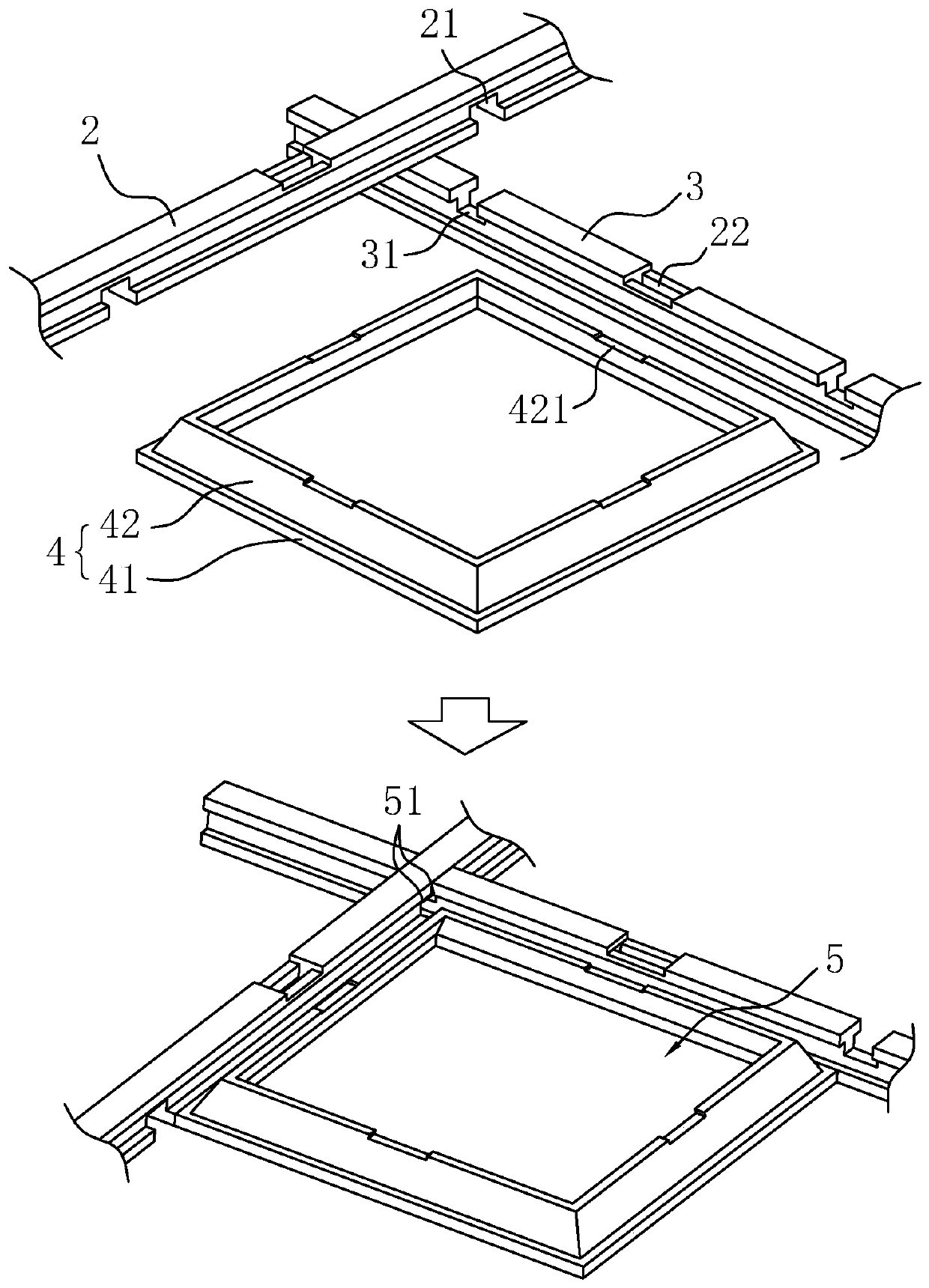

[0043] refer to figure 2 The cross-sectional shapes of the forward keel 2 and the transverse keel 3 along the width direction are both I-shaped, and the lower end surface of the forward keel 2 is provided with a plurality of positioning grooves 121, and the positioning grooves 121 are uniform along the length direction of the forward keel 2 Distribution, the depth of the positioning groove 1 21 is half of the height of the keel 2 along the direction and penetrates through the two side...

Embodiment 2

[0055] A floor construction method, using the above-mentioned floor installation structure, comprising the following steps:

[0056] Step 1: Lay horizontal keels 3 at equal intervals on the ground, and then lay forward keels 2 on the horizontal keels 3. The forward keels 2 and the horizontal keels 3 are interlocked with each other through positioning groove 1 21 and positioning groove 2 31 to form a cross shape.

[0057] Step 2: Install the filling frame 4 in the installation cavity 5, and install the positioning block 6 in the first slot 22.

[0058] Step 3: Personnel determine the position on the ground that does not need to walk according to the required walking range. This position is used to install the first batch of floor boards 1; before installing floor boards 1, inject cement into the side frame 42 and the forward keel 2 In the frame-shaped space between the 3 keels, the floor plate 1, the forward keel 2, and the transverse keel 3 are also coated with cement, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com