Girdle ring device with friction sheets

A friction plate and waist ring technology, which is applied in the field of friction plate waist ring devices, can solve the problems of uneven height of power towers, time-consuming and laborious maintenance and replacement, and time-consuming and laborious disassembly and maintenance, so as to improve work efficiency and facilitate installation, disassembly and maintenance , the effect of reducing safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

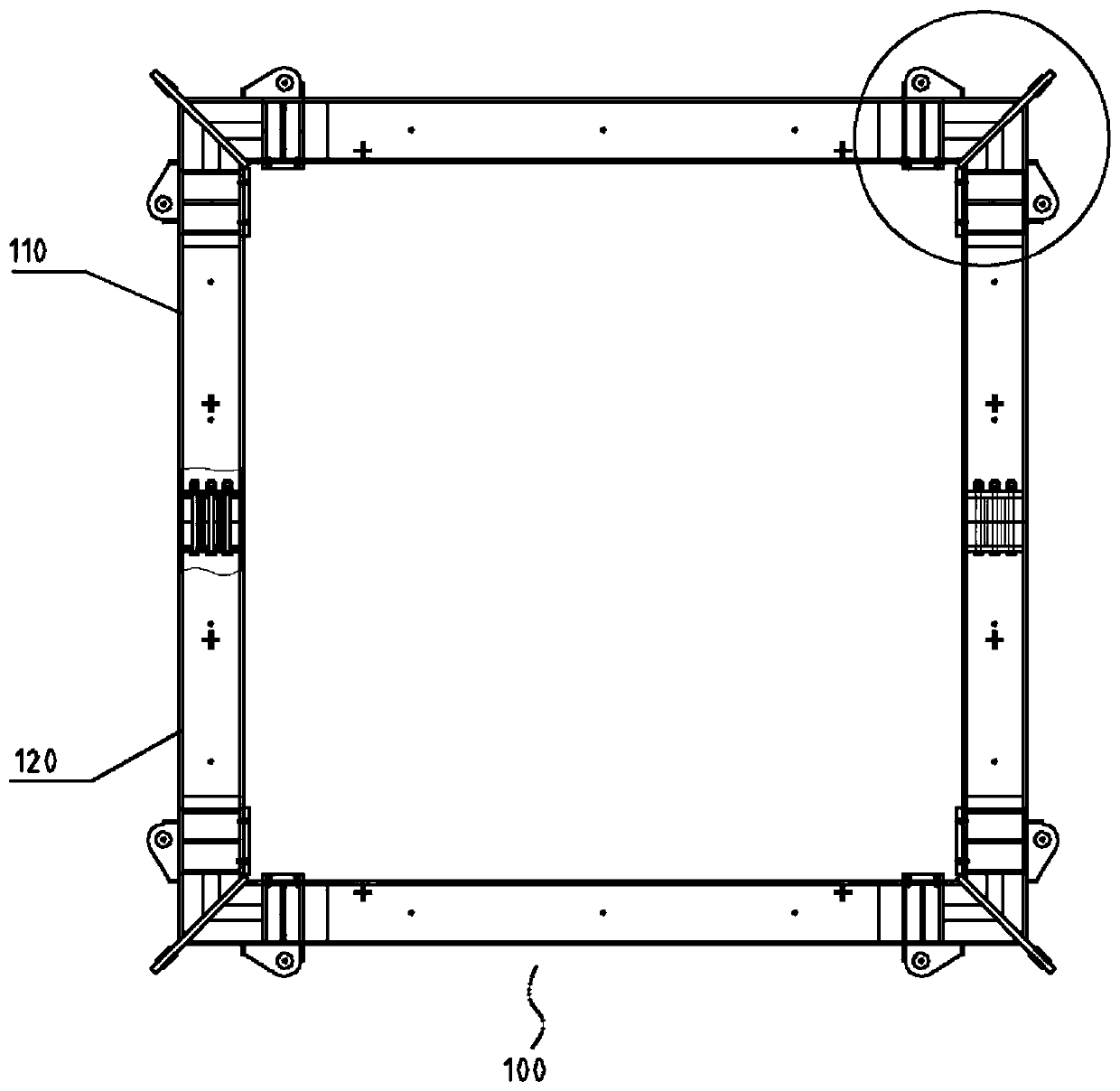

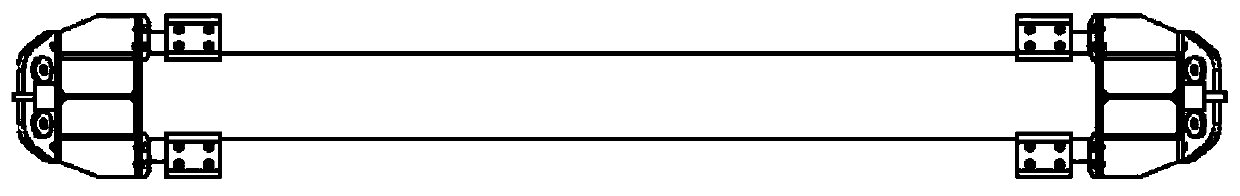

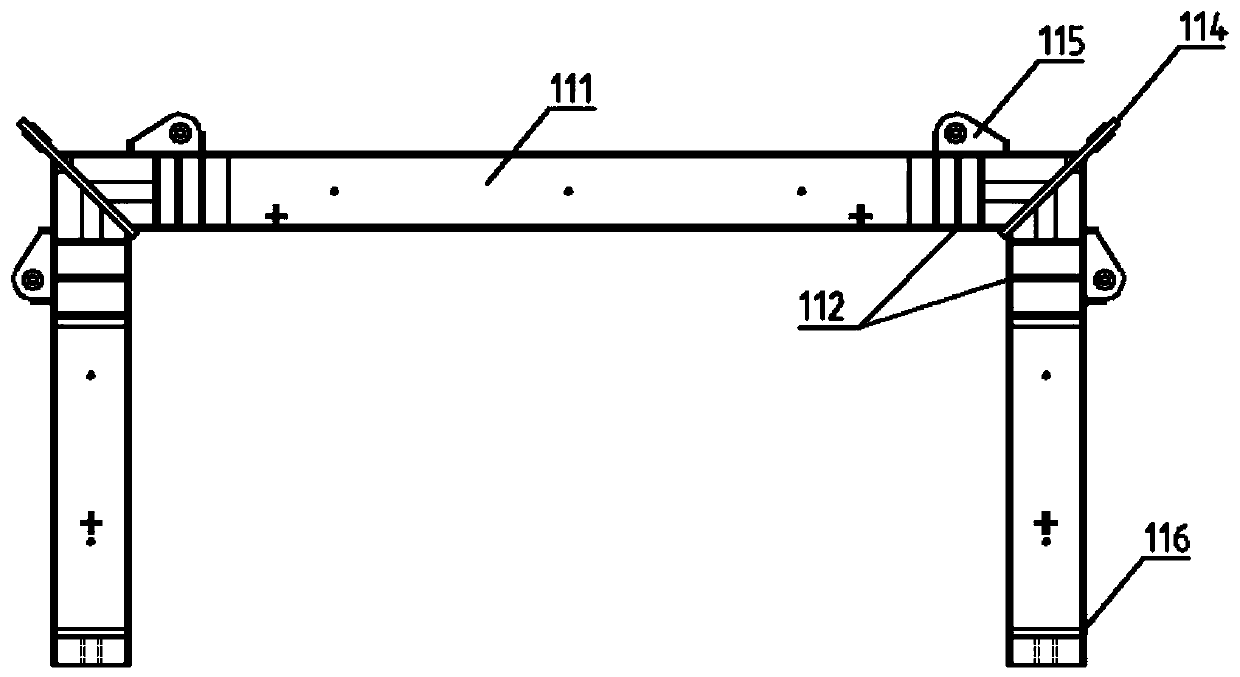

[0031] like Figure 1-7 As shown, a waist ring device 100 includes two door-shaped waist ring half-frames 110, 120 connected with each other and having the same structure and four waist ring hoop devices 130. Taking the waist ring half-frame 110 as an example, the waist ring half-frame 110 includes a waist ring semi-frame body 111, four friction plate bottom plates 112, four friction plates 113 (in order to illustrate the position of the friction bottom plate, image 3 Not drawn in), two main backguy panels 114, four anti-new backguy panels 115.

[0032] The two sections of the waist ring half frame body 110 are fixedly connected with flange plates 116, and the two waist ring half frames with the same structure are overlaid on the standard joints, and the flange plates of the corresponding sections are connected and fixed by bolt assemblies to form a The waist ring device is described to ensure that the waist ring device is firm and reliable, and it is convenient to disassemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com