Automatic control method for large-flow seawater pump unit for ship exhaust gas cleaning

An automatic control and exhaust gas cleaning technology, applied in the field of ship exhaust gas, can solve the problems of wear and tear, large failures, multiple power sources, cumbersome work, etc., to reduce the use of electric power, ensure trouble-free time, and eliminate the effect of manual operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

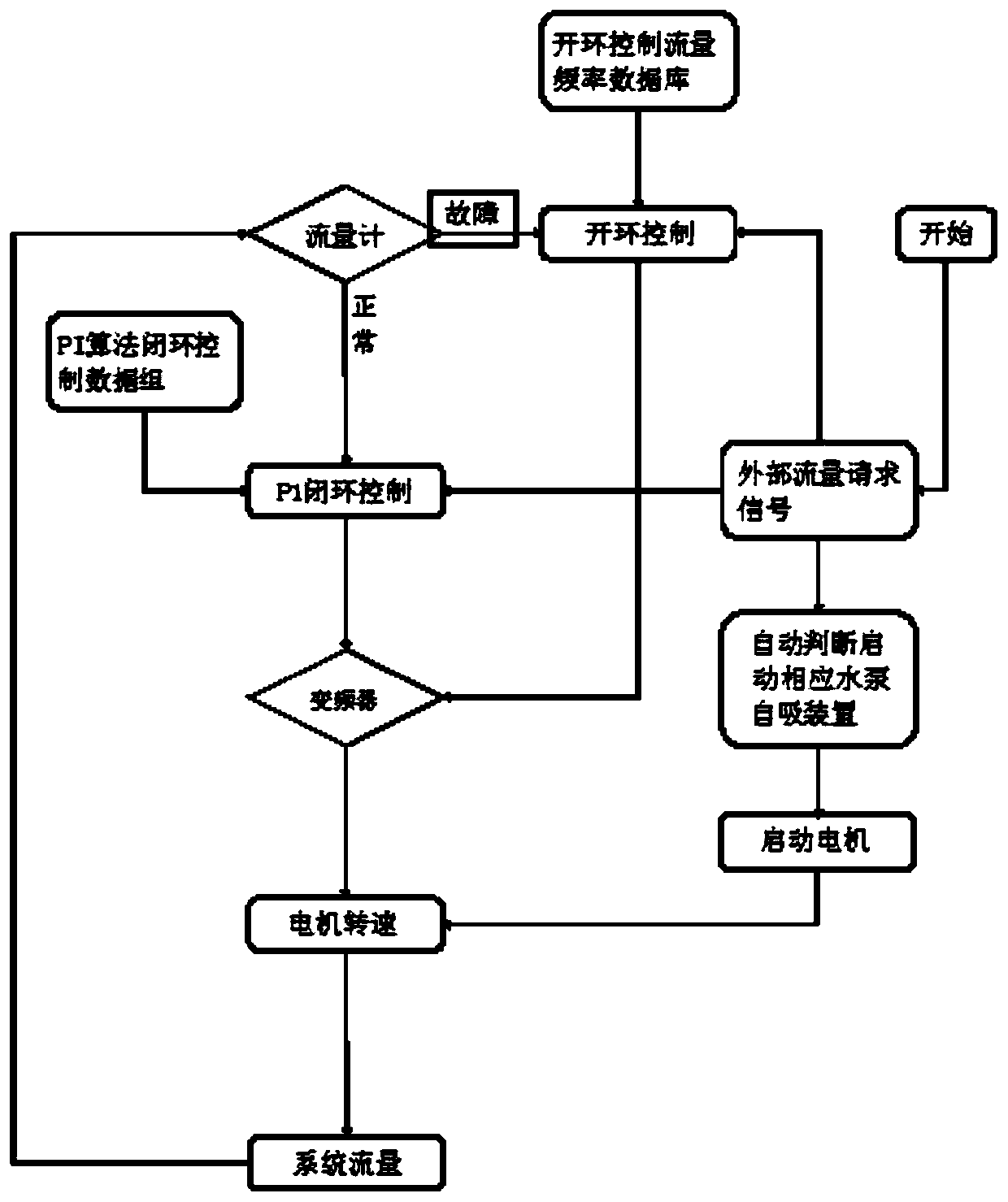

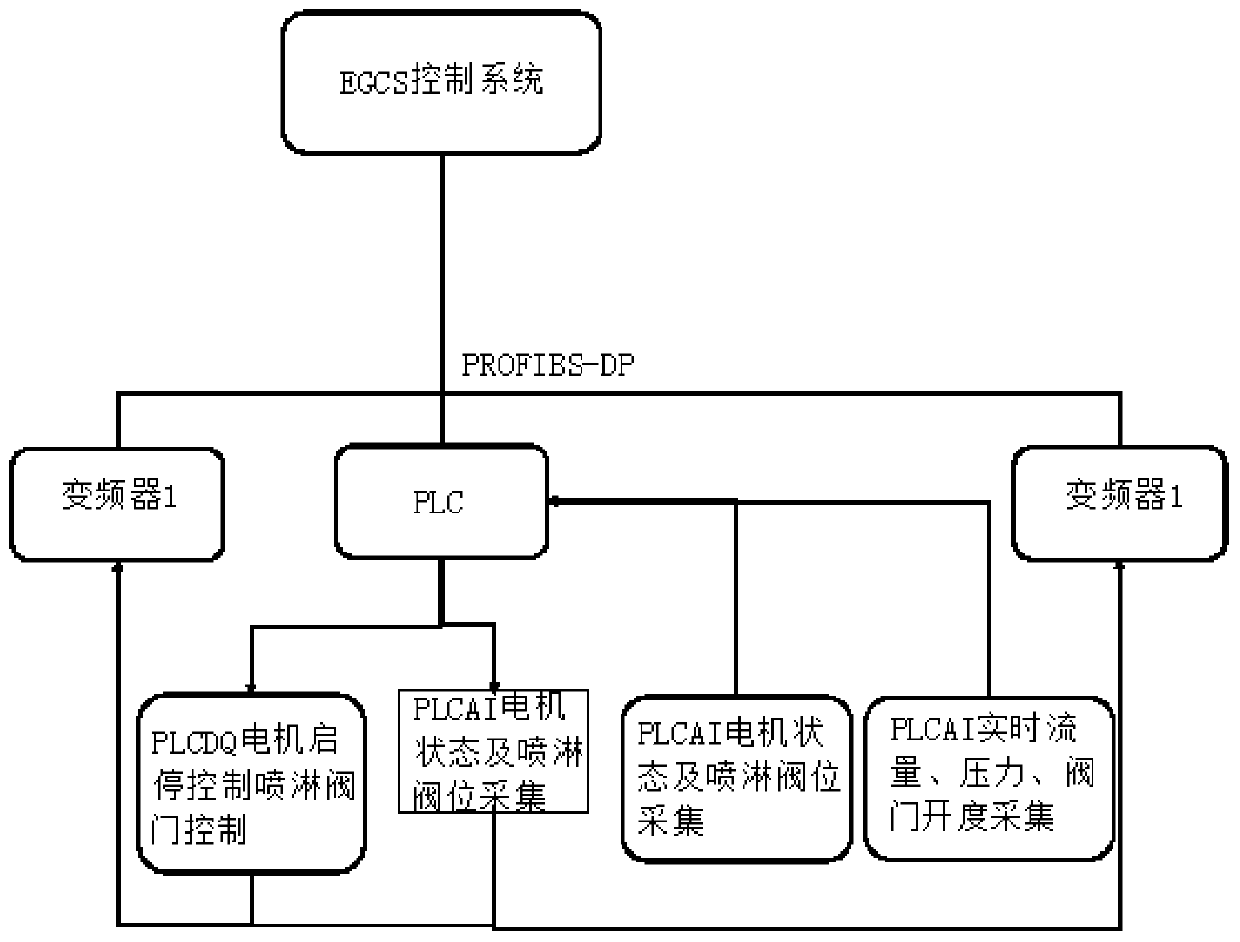

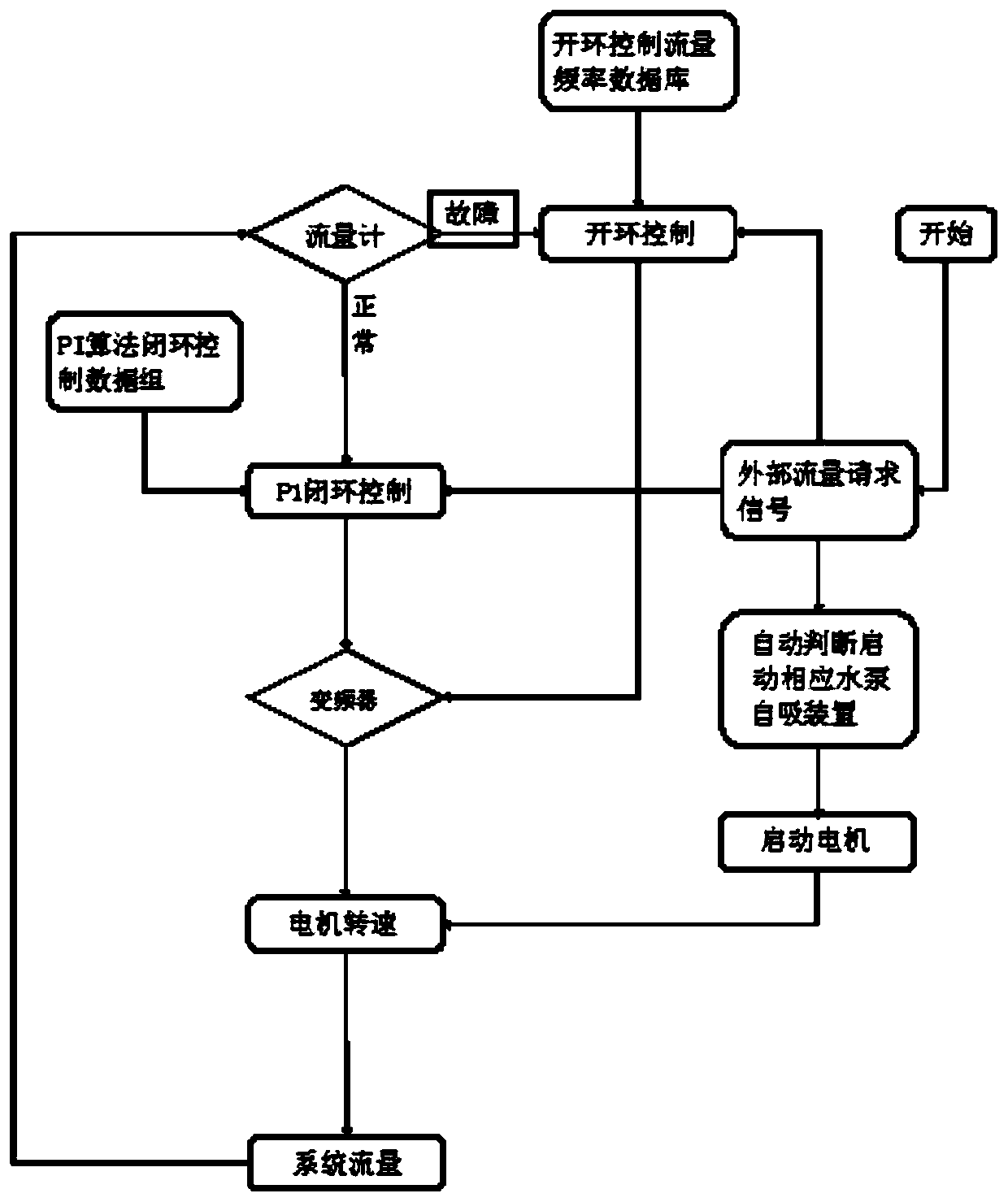

[0042] Such as Figure 1-2 As shown, this embodiment adopts the following technical solutions:

[0043] An automatic control method for a large-flow seawater pump set for ship exhaust gas cleaning, including preparation work, a space heater, a self-priming device, pump control and flow control.

[0044] Among them, the preparatory work mainly includes two steps. First, check the pipeline and valve parts, and then connect the two power sources.

[0045] Among them, the space heater is first turned to the on position, the space heater starts to run, and the pump is automatically cut off when it is running.

[0046] Among them, the self-priming device is first started before starting the pump, and the pump is restarted after a delay (the time is determined according to the self-priming effect); when the pressure is reached, the self-priming device stops working.

[0047] Among them, pump control includes manual control, automatic control and emergency stop;

[0048] 4.1. There...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com