Spacer wire clamp rubber column packing tool

A technology of rubber columns and spacers, applied in the direction of overhead line/cable equipment, etc., can solve the problems of high purchase cost, high labor intensity, damaged rubber columns, etc., and achieve the effect of strong application value and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

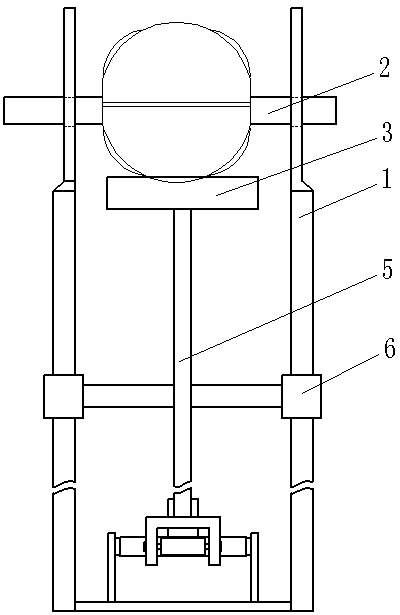

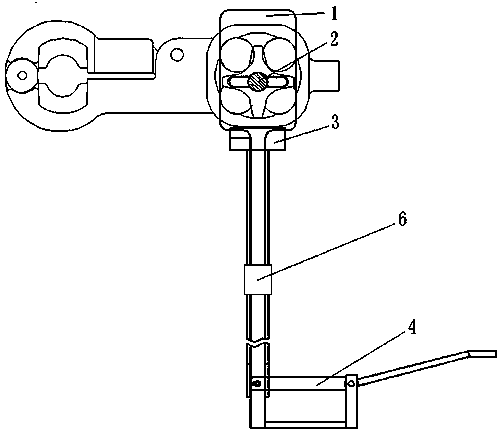

[0014] Such as figure 1 , figure 2 , image 3 As shown, the spacer rod wire clip rubber column filling tooling of the present invention includes two discrete support bodies 1, a straight rod 2, a pressing plate 3 and a pressing plate driving device; the straight rod 2 is movably inserted into the two support bodies 1 In the rod hole provided on the upper part; the pressing plate 3 is arranged between the two support bodies 1 below the straight rod 2, and the pressing plate 3 is connected to the pressing plate driving device and moves up and down under its action.

[0015] The pressing plate driving device is a pedal lever mechanism 4, the lever mechanism 4 is connected with the pressing plate connecting rod 5 through a rotating shaft, the pressing plate connecting rod 5 is fixedly connected with the pressing plate 3, and the pressing plate connecting rod 5 is fixedly connected with a guide sleeve arranged outside the bracket body 6. To ensure that the pressure plate 3 is no...

Embodiment 2

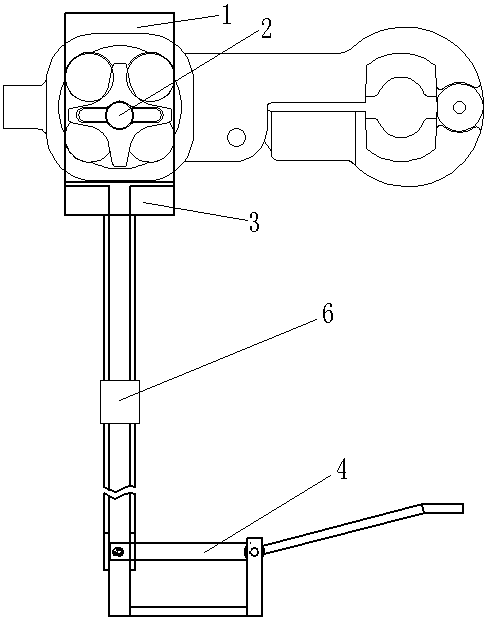

[0017] Such as Figure 4 As shown, the spacer rod wire clip rubber column filling tooling of the present invention includes two discrete support bodies 1, a straight rod 2, a pressing plate 3 and a pressing plate driving device; the straight rod 2 is movably inserted into the two support bodies 1 In the rod hole provided on the upper part; the pressing plate 3 is arranged between the two support bodies 1 below the straight rod 2, and the pressing plate 3 is connected to the pressing plate driving device and moves up and down under its action.

[0018] The platen driving device is a pneumatic telescopic rod 7 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap