Feeding device for aquaculture

A feeding device and aquaculture technology, applied in fish farming, application, climate change adaptation, etc., can solve the problems of high labor intensity, looting of fish, concentrated feed throwing, etc., to reduce labor intensity, improve feeding efficiency, and facilitate The effect of delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

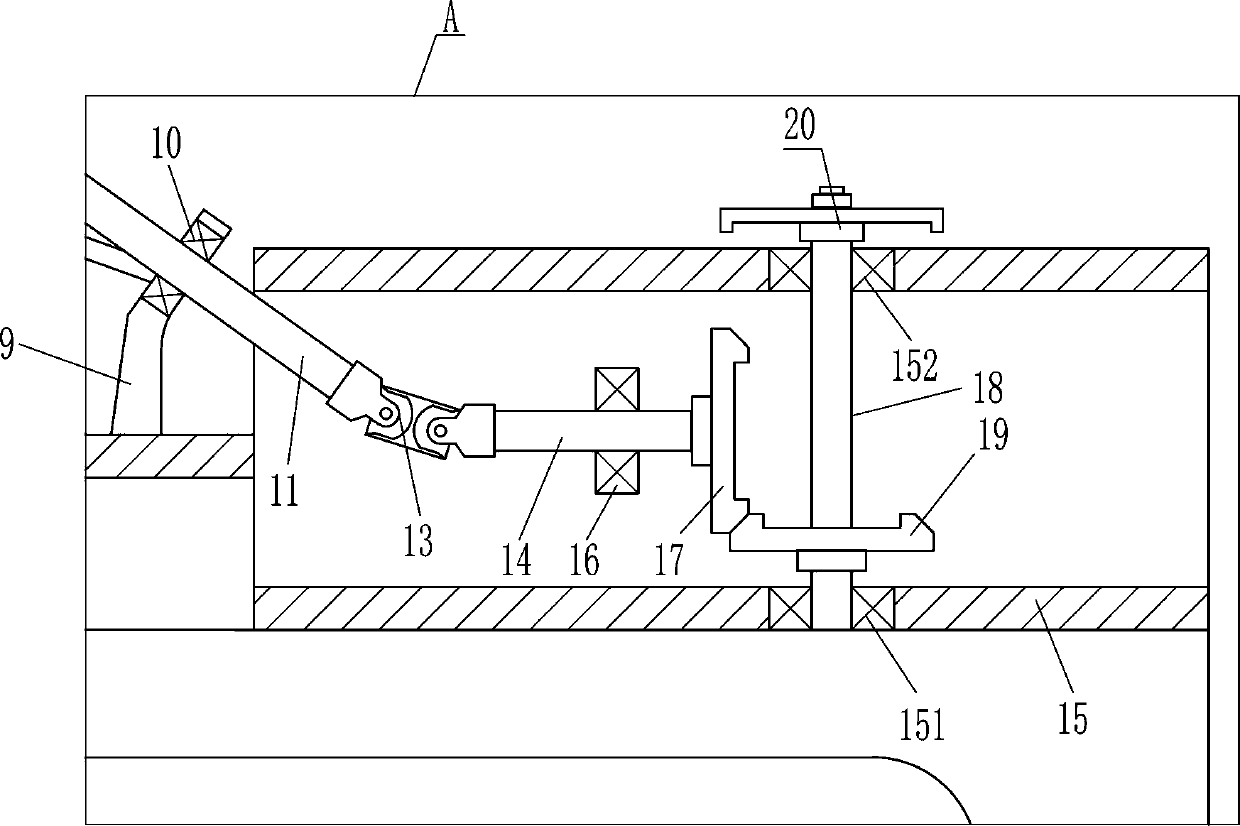

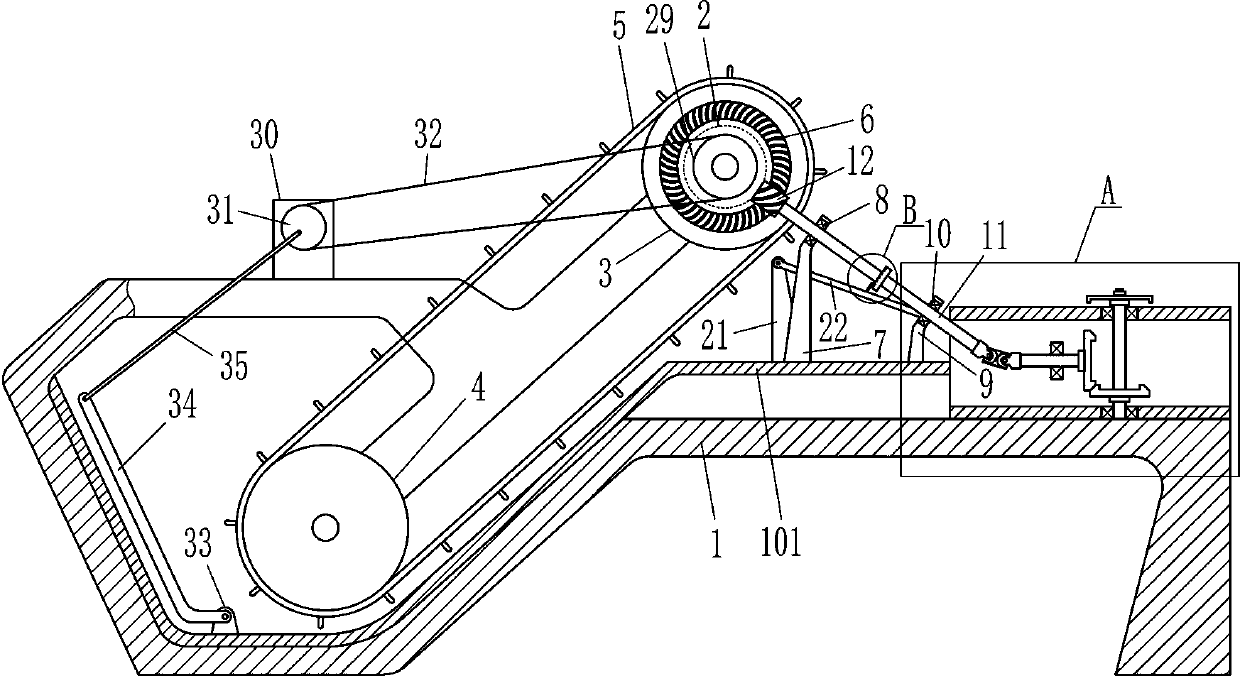

[0018] A feeding device for aquaculture, such as Figure 1-4 As shown, it includes a frame 1, a hopper 101, a motor 2, a first idler roller 3, a second idler roller 4, a partition lifting conveyor belt 5, a gear plate 6, a first bracket 7, a first bearing 8, a second Support 9, second bearing 10, first rotating shaft 11, helical tooth wheel 12, Vientiane coupling 13, second rotating shaft 14, throwing table 15, third bearing 151, fourth bearing 152, fifth bearing 16, the first One bevel gear 17, the third rotating shaft 18, the second bevel gear 19, the material throwing mechanism 20, the third support 21 and the material plate 22, the bottom left side in the frame 1 is equipped with a hopper 101, and the motor 2 is installed on the frame 1 On the upper part of the rear side, the motor 2 is connected to the frame 1 through bolt connection, the front end of the output shaft of the motor 2 passes through the frame 1, and the front end of the output shaft of the motor 2 is fixedl...

Embodiment 2

[0020] A feeding device for aquaculture, such as Figure 1-4As shown, it includes a frame 1, a hopper 101, a motor 2, a first idler roller 3, a second idler roller 4, a partition lifting conveyor belt 5, a gear plate 6, a first bracket 7, a first bearing 8, a second Support 9, second bearing 10, first rotating shaft 11, helical tooth wheel 12, Vientiane coupling 13, second rotating shaft 14, throwing table 15, third bearing 151, fourth bearing 152, fifth bearing 16, the first One bevel gear 17, the third rotating shaft 18, the second bevel gear 19, the material throwing mechanism 20, the third support 21 and the material plate 22, the bottom left side in the frame 1 is equipped with a hopper 101, and the motor 2 is installed on the frame 1 On the upper part of the rear side, the front end of the output shaft of the motor 2 passes through the frame 1, and the front end of the output shaft of the motor 2 is fixedly connected with the first roller 3, and the lower part of the fro...

Embodiment 3

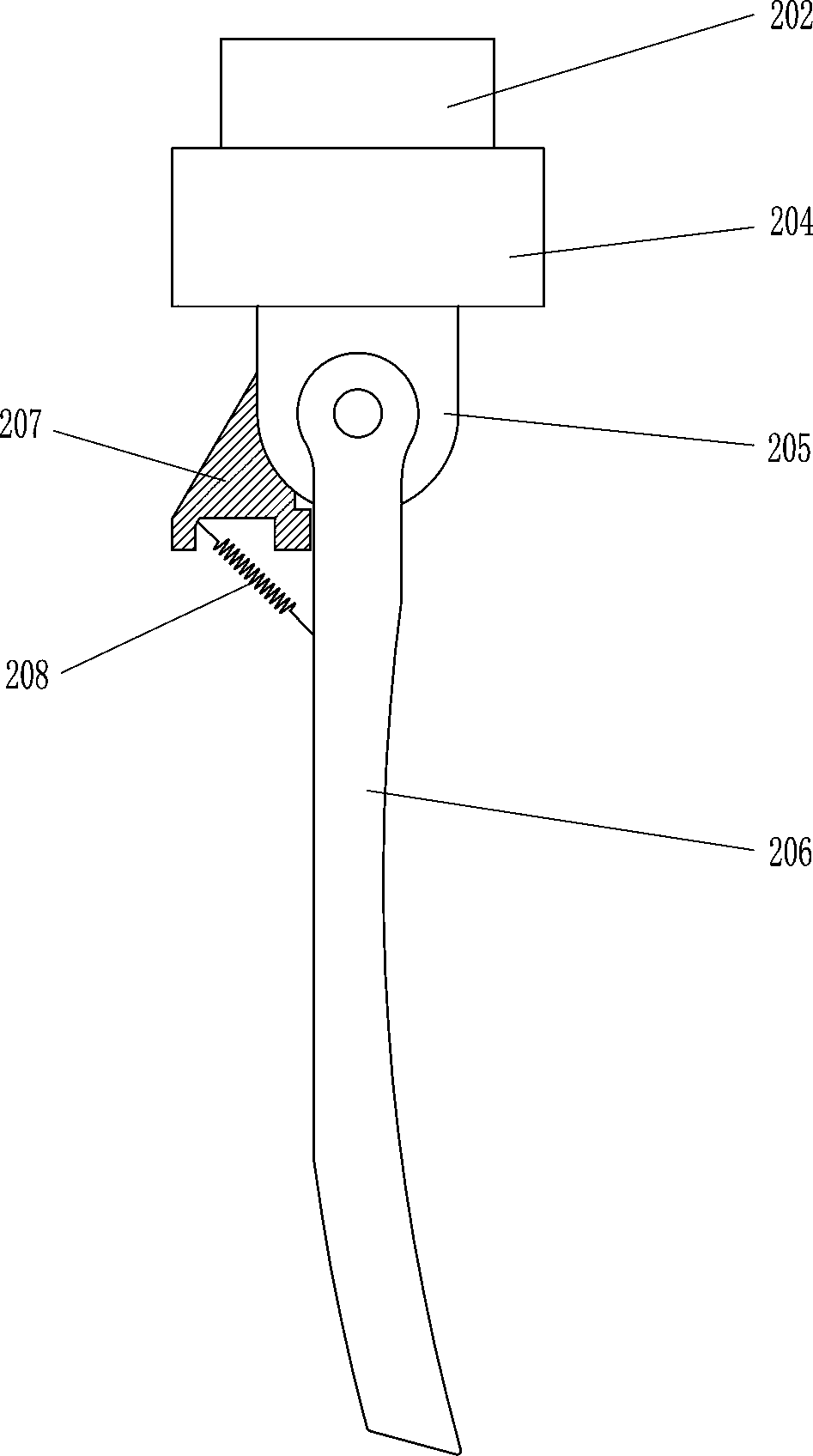

[0023] A feeding device for aquaculture, such as Figure 1-5 As shown, it includes a frame 1, a hopper 101, a motor 2, a first idler roller 3, a second idler roller 4, a partition lifting conveyor belt 5, a gear plate 6, a first bracket 7, a first bearing 8, a second Support 9, second bearing 10, first rotating shaft 11, helical tooth wheel 12, Vientiane coupling 13, second rotating shaft 14, throwing table 15, third bearing 151, fourth bearing 152, fifth bearing 16, the first One bevel gear 17, the third rotating shaft 18, the second bevel gear 19, the material throwing mechanism 20, the third support 21 and the material plate 22, the bottom left side in the frame 1 is equipped with a hopper 101, and the motor 2 is installed on the frame 1 On the upper part of the rear side, the front end of the output shaft of the motor 2 passes through the frame 1, and the front end of the output shaft of the motor 2 is fixedly connected with the first roller 3, and the lower part of the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com