Spray nozzle opened through action of heat sensitive element

A heat-sensitive, component technology, applied in fire rescue, etc., can solve problems such as early spraying, economic loss, uneven structural strength, etc., to avoid mis-spraying and early spraying, improve assembly efficiency, and simplify the action structure of heat-sensitive components Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

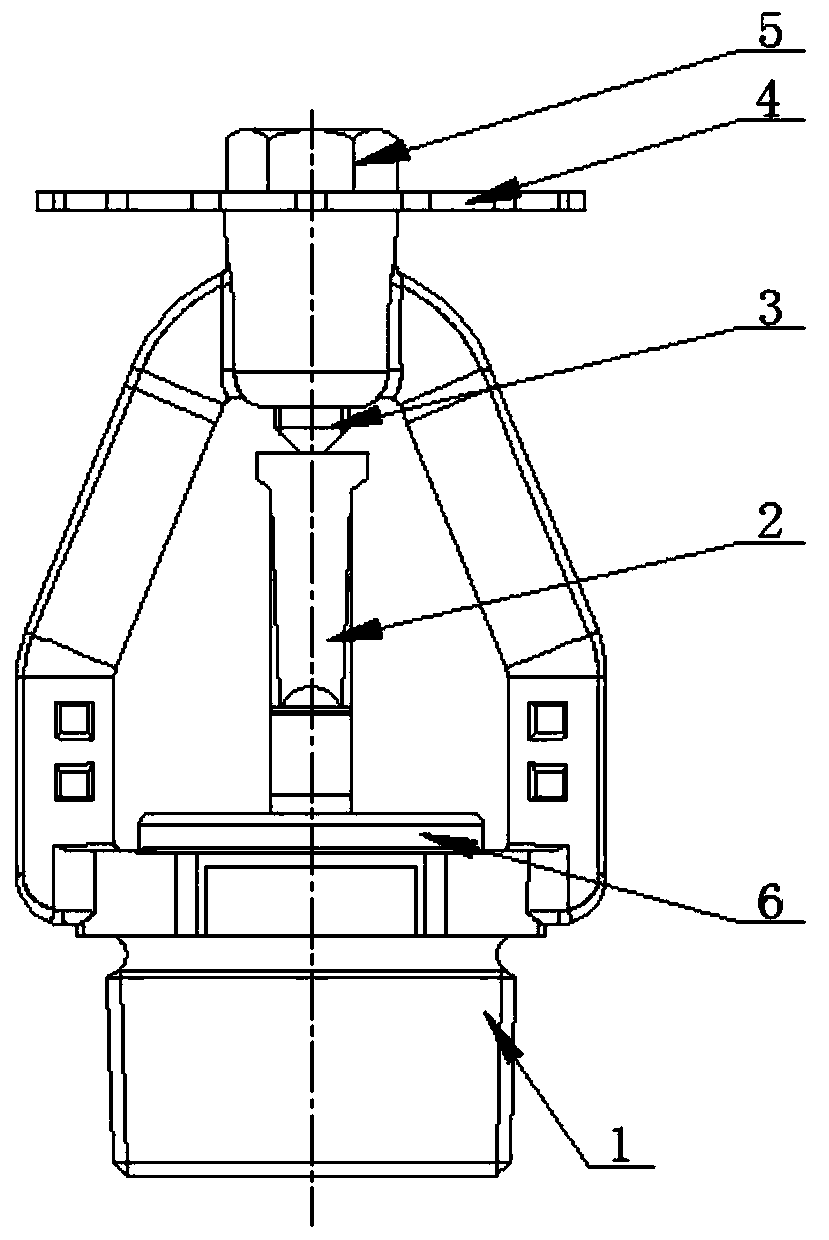

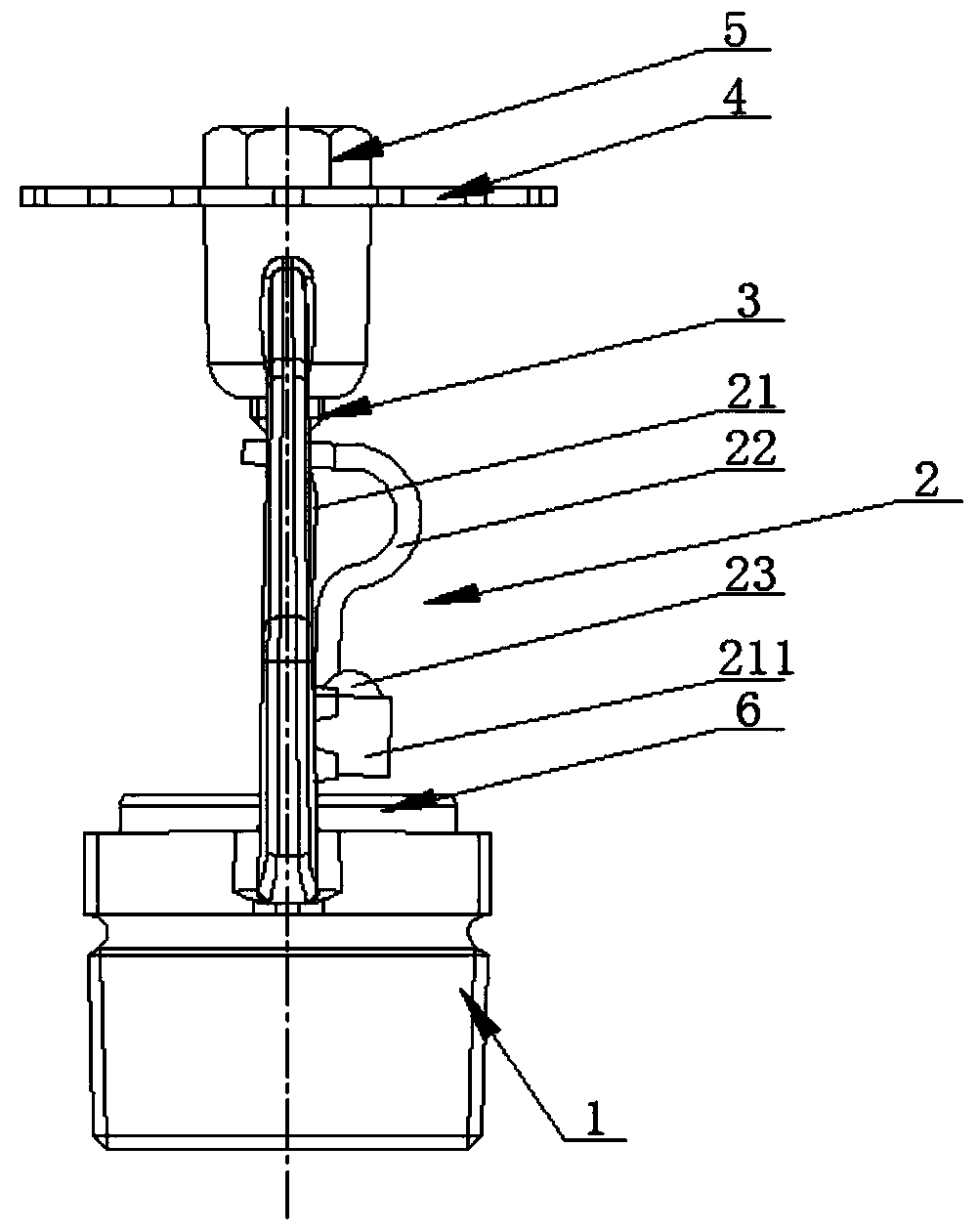

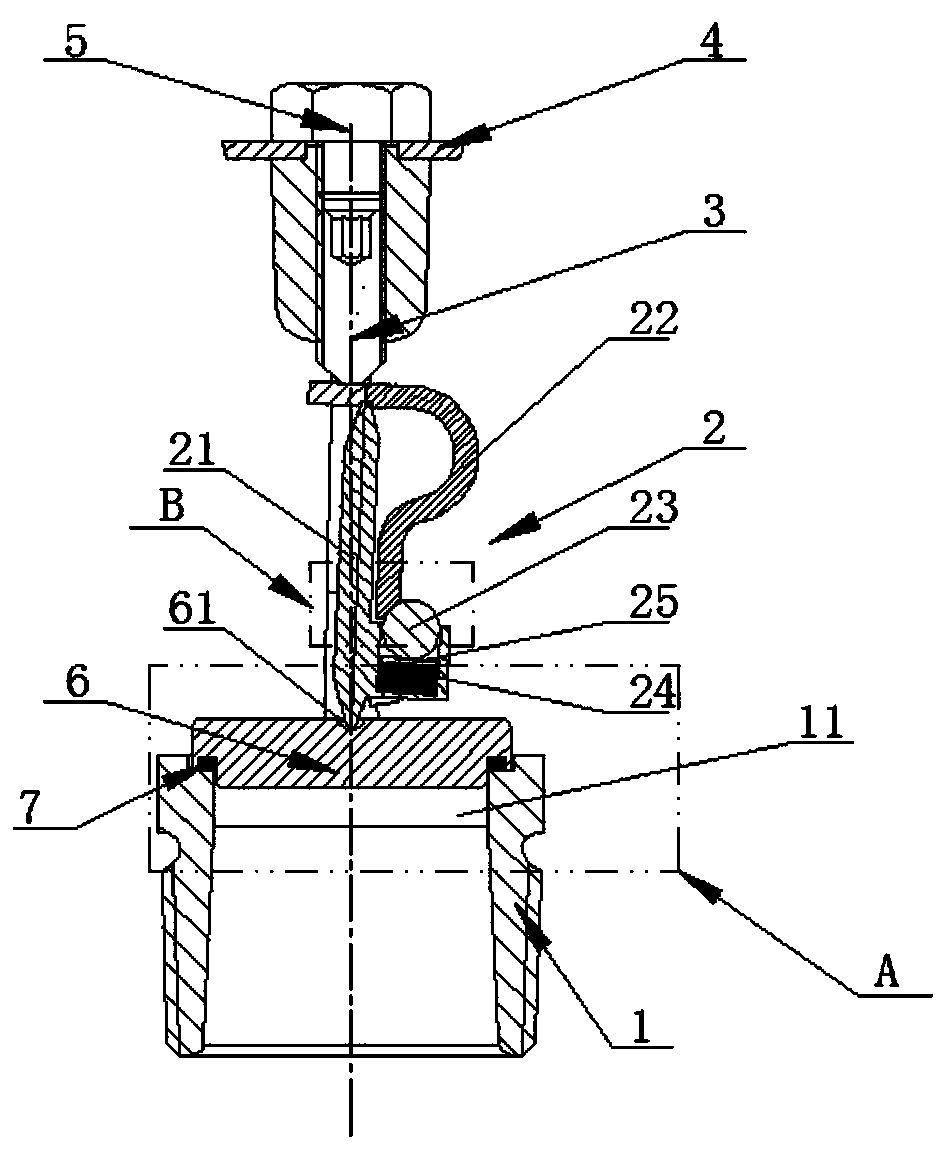

[0023] This embodiment is: a shower head with a thermal sensitive element action structure, such as figure 1 As shown, including the frame (1), the top and bottom of the frame (1) are respectively provided with a pre-tightening screw (3) and a sealing seat (6), and a lever is installed between the pre-tightening screw (3) and the sealing seat (6) component(2); as in figure 2 , image 3 and Figure 6 As shown, the lever assembly (2) includes a bracket (21), a balance frame (22), a steel ball (23), a gasket (25) and a fusible alloy (24), such as Figure 4 As shown, the bottom of the bracket (21) is provided with a bracket hole (211), and the fusible alloy (24), gasket (25) and steel ball (23) are respectively embedded in the bracket hole (211), and the gasket (25) Placed on the fusible alloy (24) and pressed by steel balls (23), the function of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com