Pneumatic tool capable of adjusting torque force

A pneumatic tool and torque technology, applied in the field of adjustable torque pneumatic tools, can solve the problems that the torque output cannot be adjusted separately, the design is difficult, and it is not easy to conform to the working habits of practitioners, so as to increase the volume or weight and be easy to use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] In order to be able to understand the technical features and practical effects of the present invention in detail, and to implement them according to the contents of the specification, the preferred embodiment shown in the accompanying drawings will be described in detail as follows:

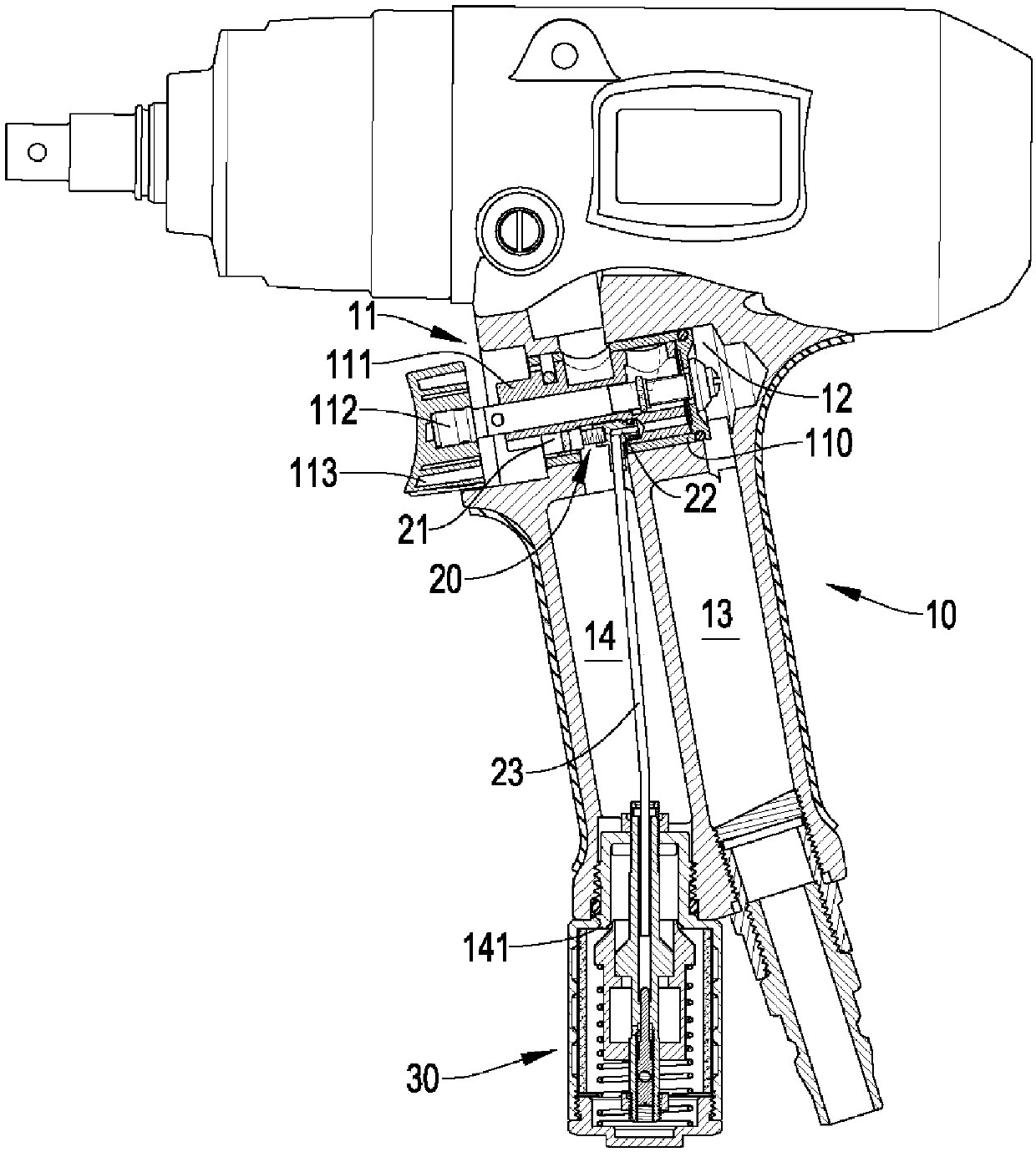

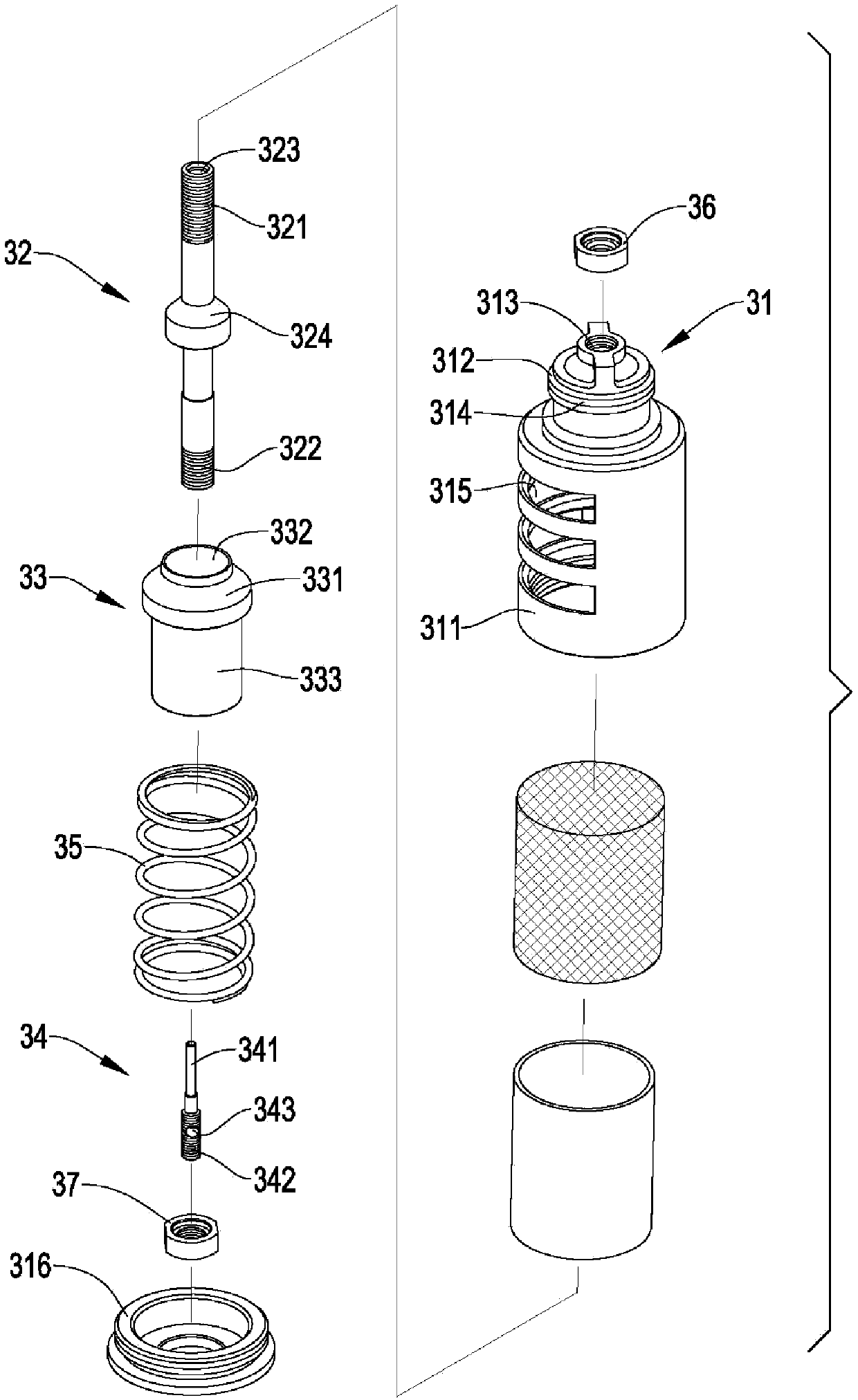

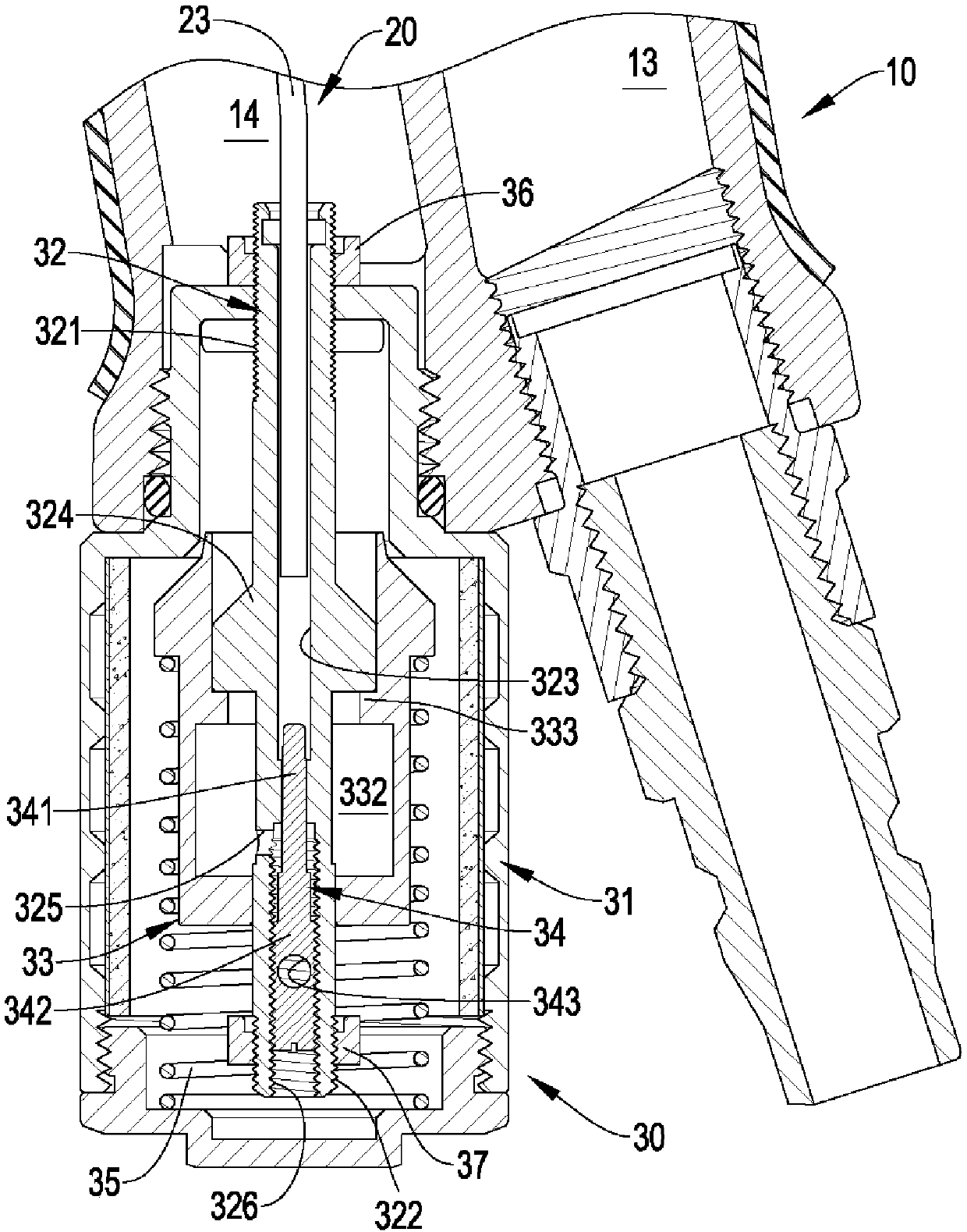

[0075] The present invention is a pneumatic tool with adjustable torque, please refer to Figure 1 to Figure 4 A preferred embodiment of the present invention includes a body 10 , a signal pressure transmission unit 20 and a torque adjustment unit 30 .

[0076] Such as figure 1 and figure 2 As shown, the body 10 is a common type of pneumatic tool on the market, including a pressing assembly 11, a pressing cavity 12 formed inside the body 10 and accommodating the pressing assembly 11, and an air inlet connected to the pressing cavity 12 respectively. channel 13 and an exhaust channel 14, the pressing assembly 11 includes a spool cover 110, a spool 111 installed inside the spool cover 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com