Intelligent electrolysis air flotation equipment used for industrial wastewater treatment

A technology for electrolytic air flotation and industrial wastewater, applied in water/sewage treatment, flotation water/sewage treatment, water/sludge/sewage treatment, etc. The effect of stable output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

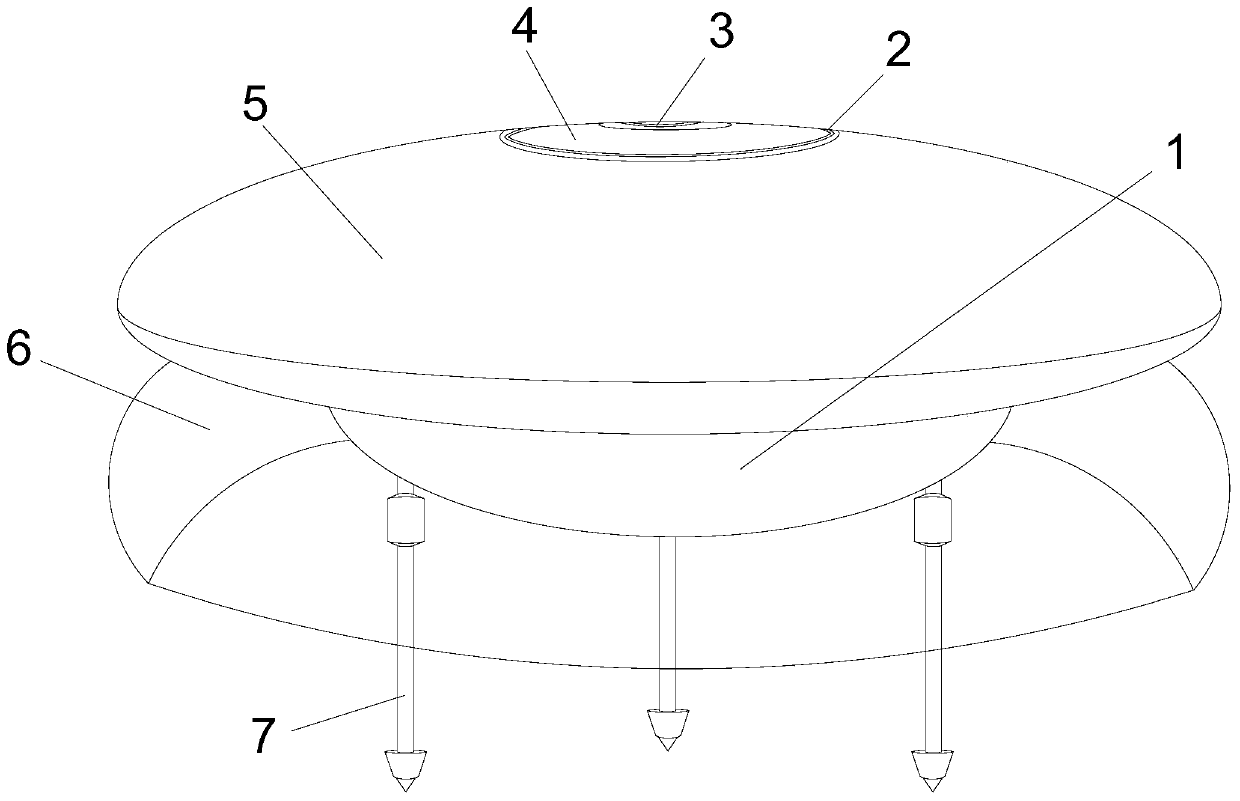

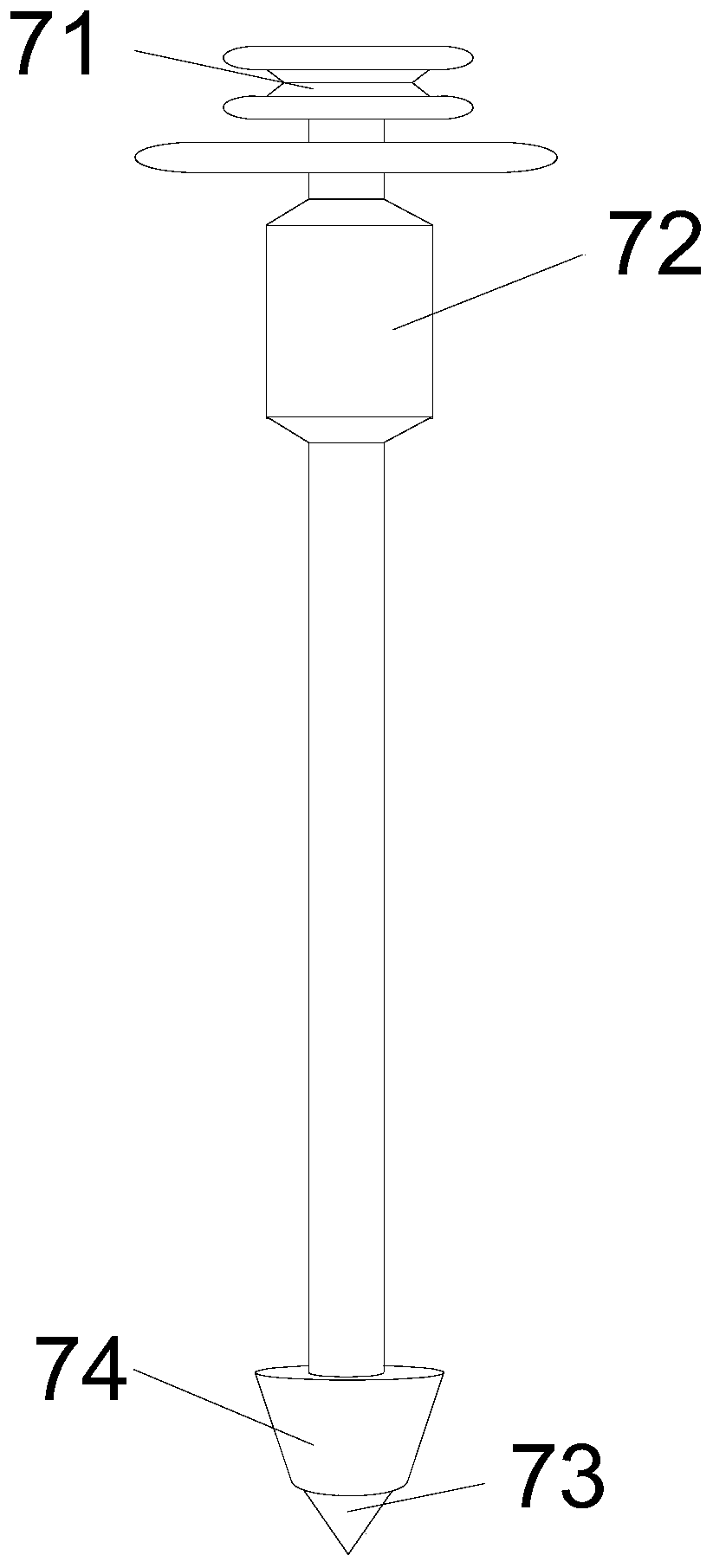

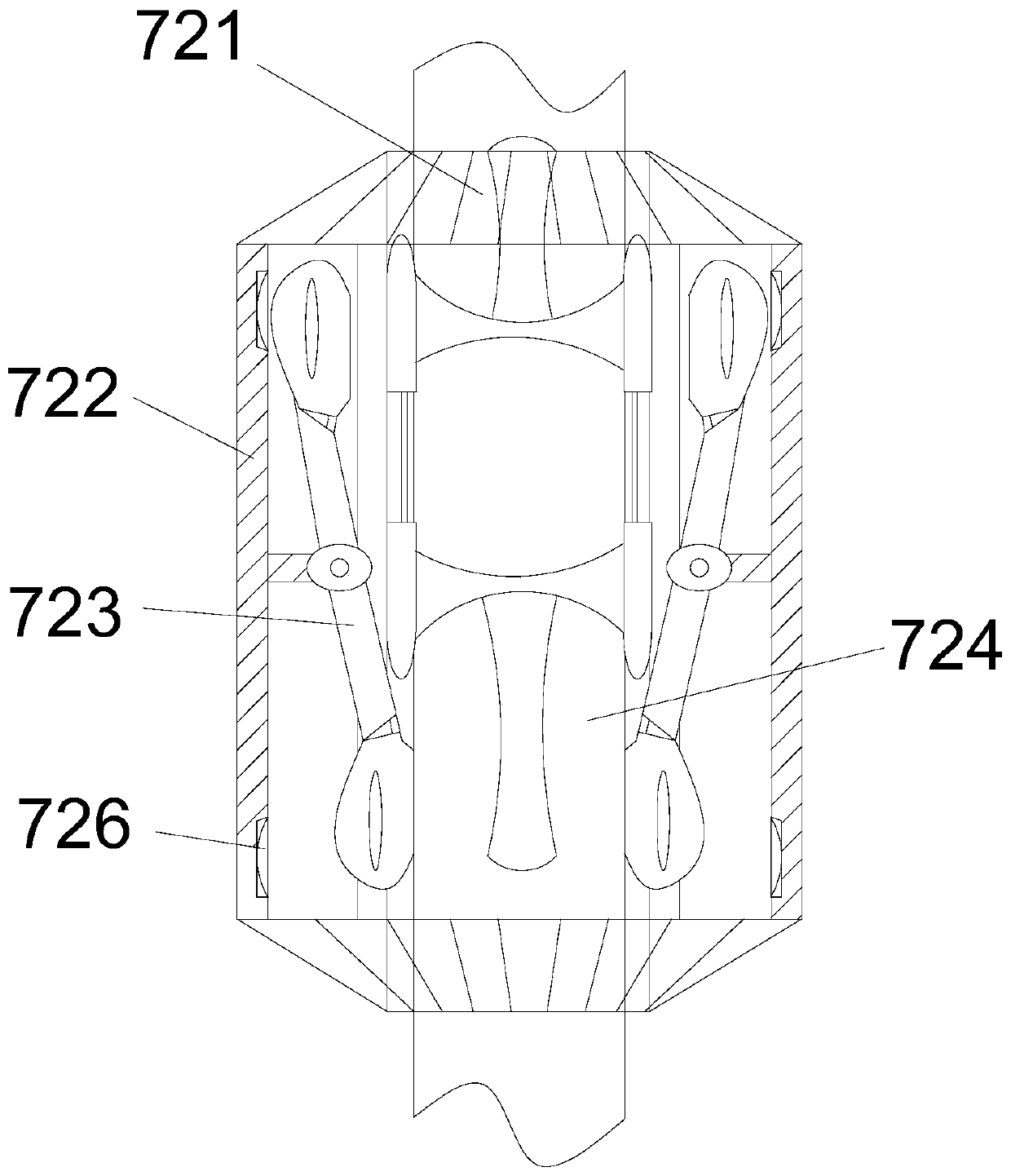

[0025] as attached figure 1 to attach Image 6 Shown:

[0026] The invention provides an intelligent electrolytic air flotation device for industrial wastewater treatment, the structure of which includes a waterproof chassis 1, a cable 2, a buckle 3, a cable stack wheel 4, an intelligent control panel 5, an air flotation plate 6, an electrolytic The reaction film stripping device 7, the electrolytic reaction film stripping device 7 is fixedly installed at the bottom of the waterproof chassis 1, the top of the air floating plate 6 is fixed at the bottom of the intelligent control panel 5, and the bottom of the cable stacking wheel 4 Installed in the middle position of the top of the intelligent control panel 5 by embedding, the bottom end of the ring buckle 3 is installed on the top of the cable stacking wheel 4 by embedding, and the cable 2 is wound inside the cable stacking wheel 4, so The electrolytic reaction film peeling device 7 includes a top connecting stacking wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com