High-tightness and high-strength vacuum glass

A vacuum glass, high-strength technology, applied in the field of glass, can solve the problems of low strength, easy damage and rupture, and achieve the effects of uniform strength, increased strength, and improved connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

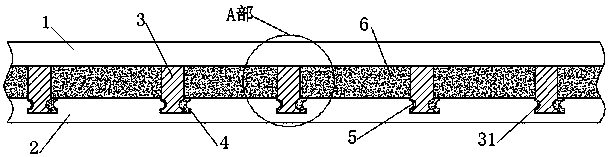

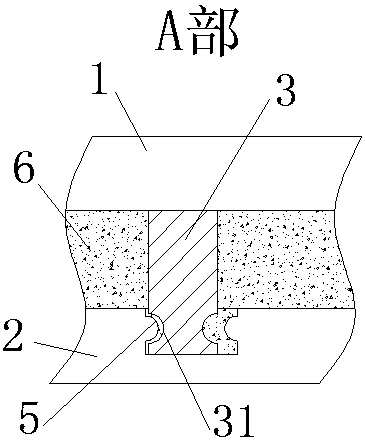

[0016] The present invention includes glass one 1 and glass two 2 which are arranged oppositely, and a plurality of support strips 3 are arranged in the vacuum layer between glass one 1 and glass two 2, and one end of said support strips 3 is fixed on glass one 1, and said The side of the glass 2 facing the support bar 3 is provided with a slot 4 into which the support bar 3 can be inserted.

[0017] A plurality of bumps 5 are provided on the surface of the card slot 4 , and a sealant 6 is filled between the card slot 4 and the support bar 3 .

[0018] A number of concave holes 31 are provided on the side of the support bar 3 .

[0019] The cross-sections of the support bar 3 and the slot 4 are both square, and they correspond to each other.

[0020] When the present invention is in use, glass one 1 and glass two 2 are docked, so that the support bar 3 is inserted into the slot 4, the long support bar 3 directly touches the glass two 2, and the shorter support bar 3 has its s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com