A temporary support device suitable for the conversion of long-span prestressed cap beam system

A system conversion and temporary support technology, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problem that the support cannot be rotated, and achieve the effects of reducing prestress loss, improving the way the support is stressed, and saving building materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

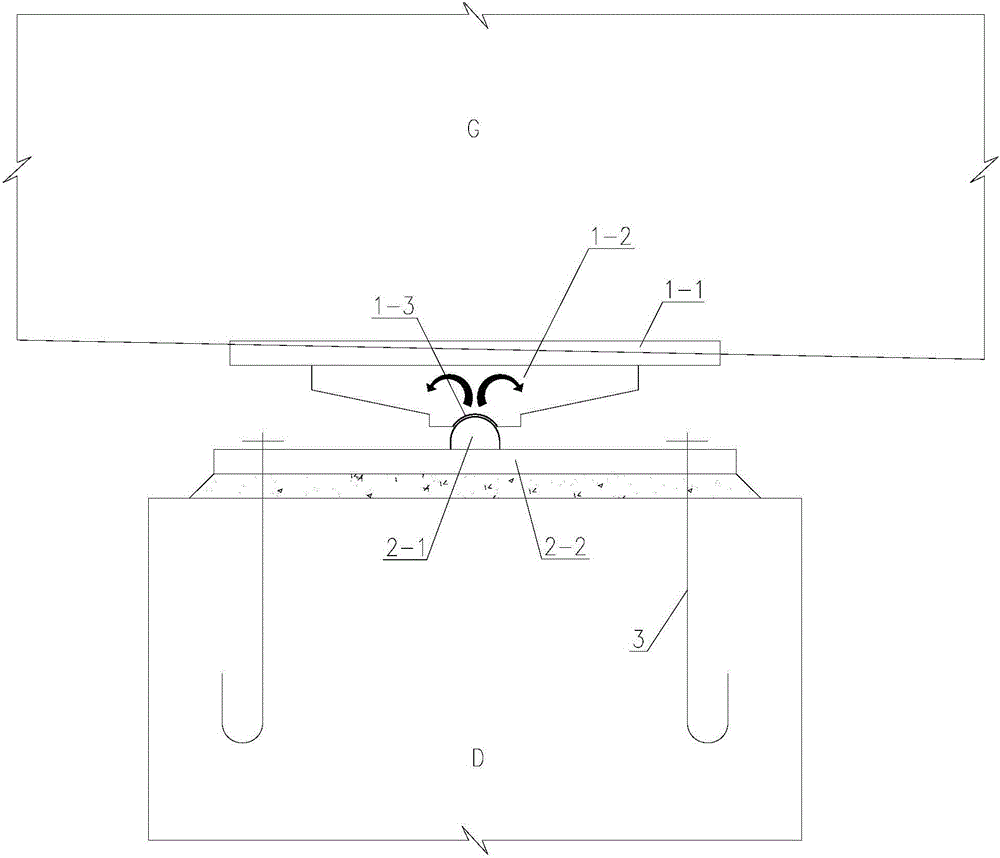

[0018] Now further illustrate how the present invention is implemented in conjunction with accompanying drawings:

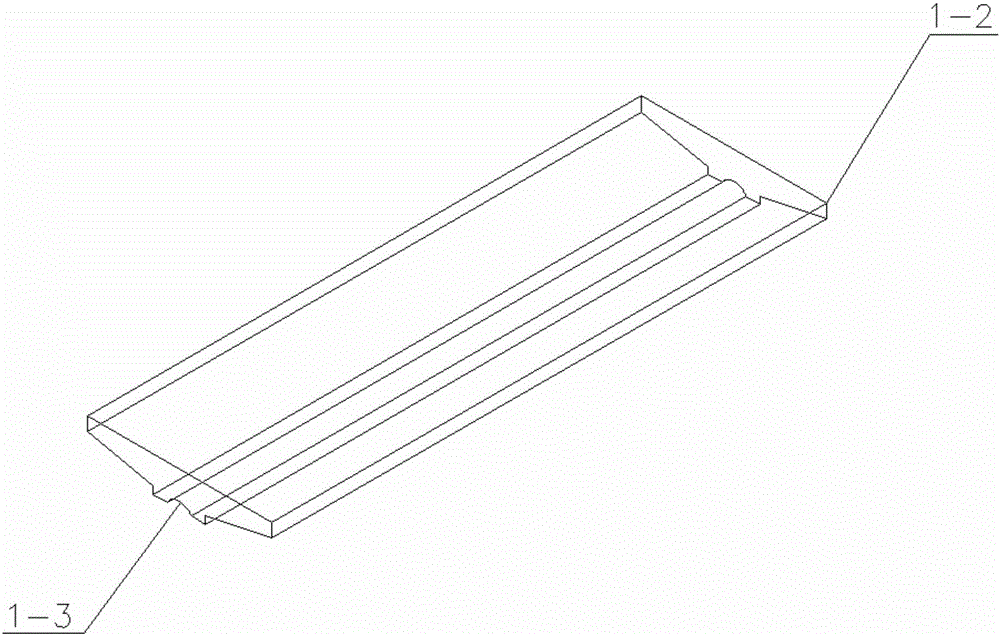

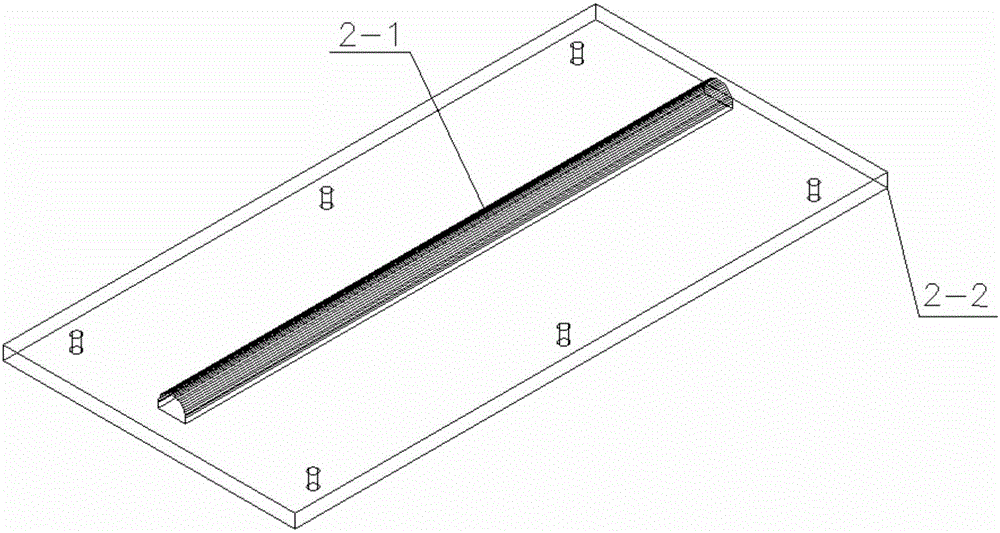

[0019] The present invention is a temporary support device suitable for the conversion of large-span prestressed cap beam systems, including an upper swivel seat and a lower pin base, the upper swivel seat 1 is composed of an upper seat plate 1-1 and a swivel seat 1-2, The center of the swivel seat 1-2 is provided with a semicircular swivel groove 1-3 with a downward notch; the lower pin base 2 is composed of a semi-ellipsoid pin 2-1 and a lower seat plate 2-2, and the semi-ellipsoid pin 2 -1 is fixedly connected to the center of the upper surface of the lower seat plate 2-2, the lower seat plate 2-2 is equipped with support bolts 3 through its bolt holes, and the upper swivel seat 1 is placed on the lower pin through its semicircular swivel groove 1-3. The upper end of the semi-elliptical cylinder pin 2-1 of the column base 2 constitutes an upper rotatable integ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com