Pre-separation type double-cavity bottle

A pre-separation, bottle body technology, applied to containers with multiple items, containers, transportation and packaging, etc., can solve the problems of leakage, cumbersome operation steps, difficult separation, etc., to prevent material waste and have a good user experience. , to ensure the effect of material activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

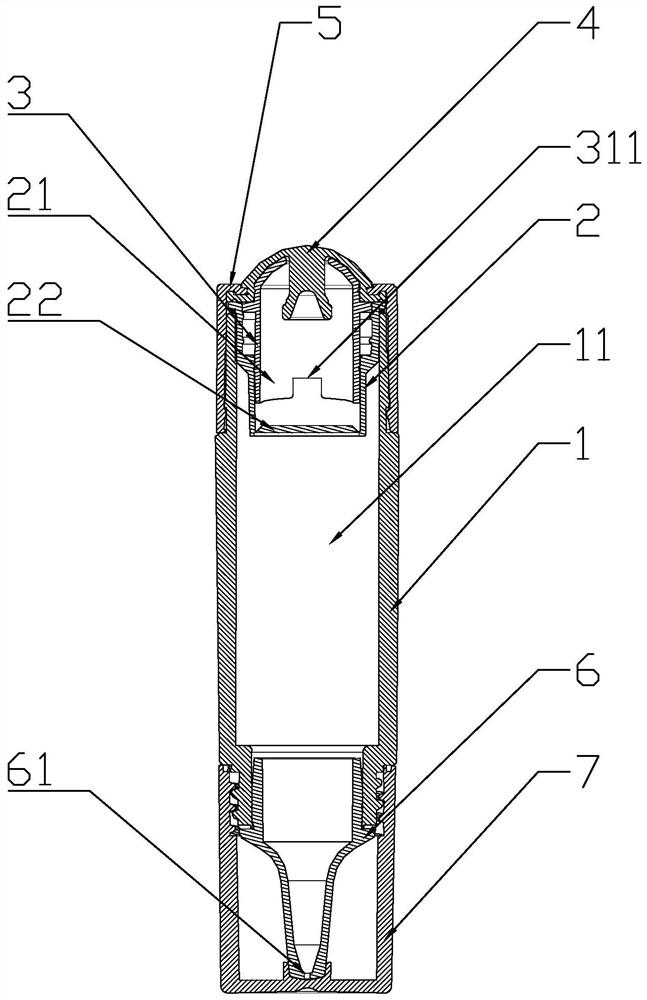

[0041] like figure 1 , figure 2 Shown, a kind of pre-separated double-chamber bottle comprises:

[0042] Bottle body 1, the bottle body 1 is a cylinder structure with two ends open, the top of the bottle body 1 is provided with a clamping structure, the bottom of the bottle body 1 is provided with threads, and the bottle body 1 is provided with a hole for accommodating the first material. Main material chamber 11;

[0043] The inner bottle body 2, the inner bottle body 1 is a cylindrical structure with an open top, the inner bottle body 1 is clamped in the top of the bottle body 1 and extends into the main material cavity 11, the top edge of the inner bottle body 1 protrudes outward and touches the Connected to the top opening of the bottle body 1, the inner bottle body 2 is provided with a secondary material cavity 21 for accommodating the second material body, and the bottom of the inner bottle body 1 is provided with a separation film for separating the main material cav...

Embodiment 2

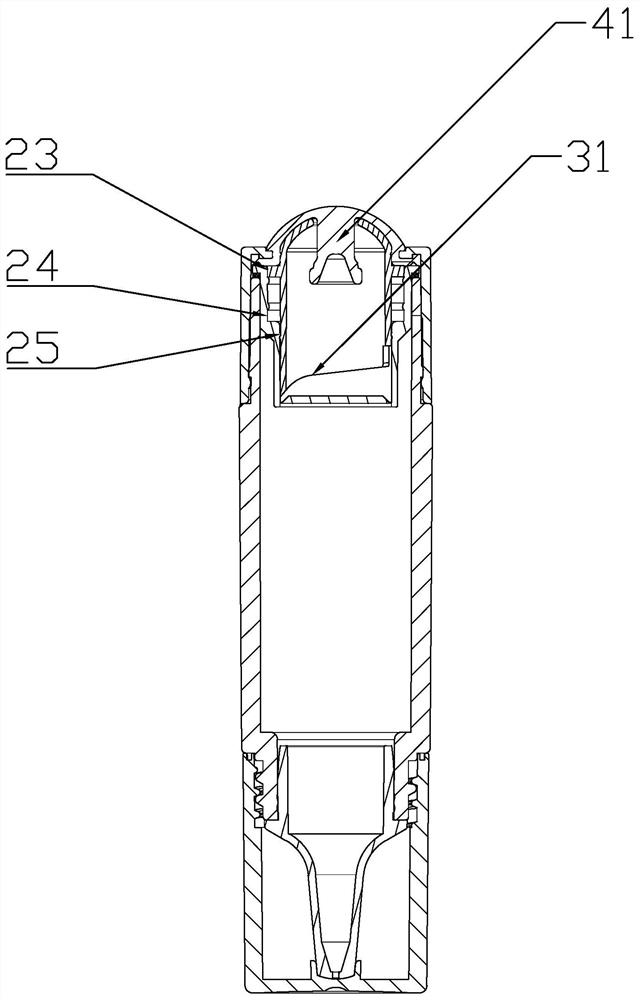

[0054] A kind of pre-separated double-chamber bottle, its structure is roughly the same as that of embodiment 1, the difference is that, as Figure 6 As shown, the original first limiting rib and the second limiting rib are connected as a whole to form the third limiting rib 26, and the upper and lower sides of the third limiting rib 26 respectively form the first limiting groove 23 and the second limiting rib. Bit slot 24. Pushing the moving part to change the state only needs to cross the third limiting rib 26, and the pressing can be done in one step, and the operation is convenient and quick. An arc-shaped plastic shrapnel is set inside the pressing part. The two ends of the shrapnel are spherically clamped in the inner wall of the pressing part. The shrapnel changes the bending degree with the pressing part, and the shrapnel is set to increase the elasticity of the pressing part. When returning to the original position, the sealing part is pressed tightly. The through ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com