Drive-by-wire mechanism of double-gear water drainage valve

A drain valve and wire-controlled technology, applied in water supply devices, flushing equipment with water tanks, buildings, etc., can solve the problems of large swing rod 5 size, small center distance, and increased center distance, so as to achieve the small space required for installation , The overall structural strength is good, and the effect of precise thread control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment one (The moving part adopts a connecting rod, the toggle device adopts a turntable, and the button seat and the wire control box are connected by a lock nut).

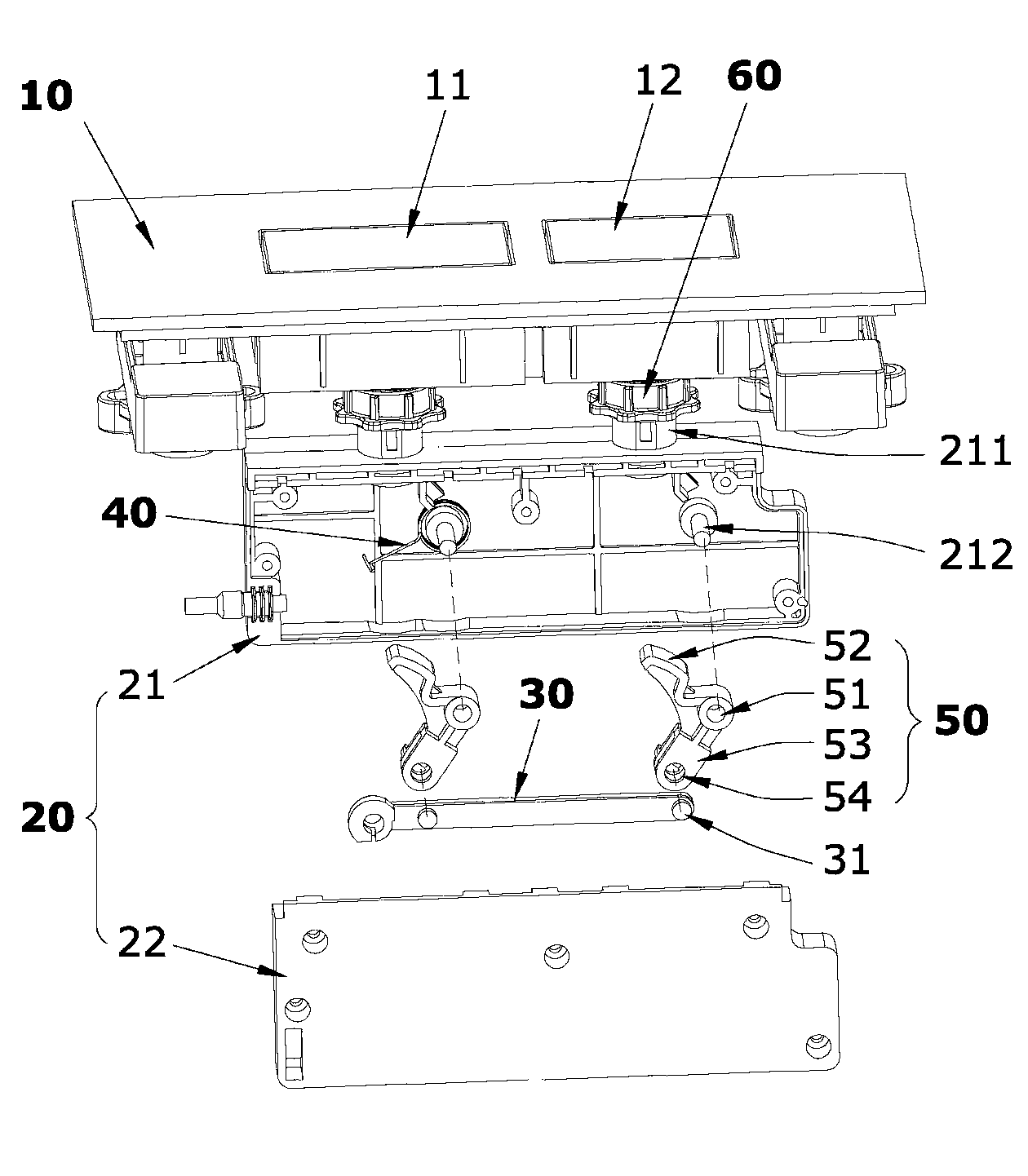

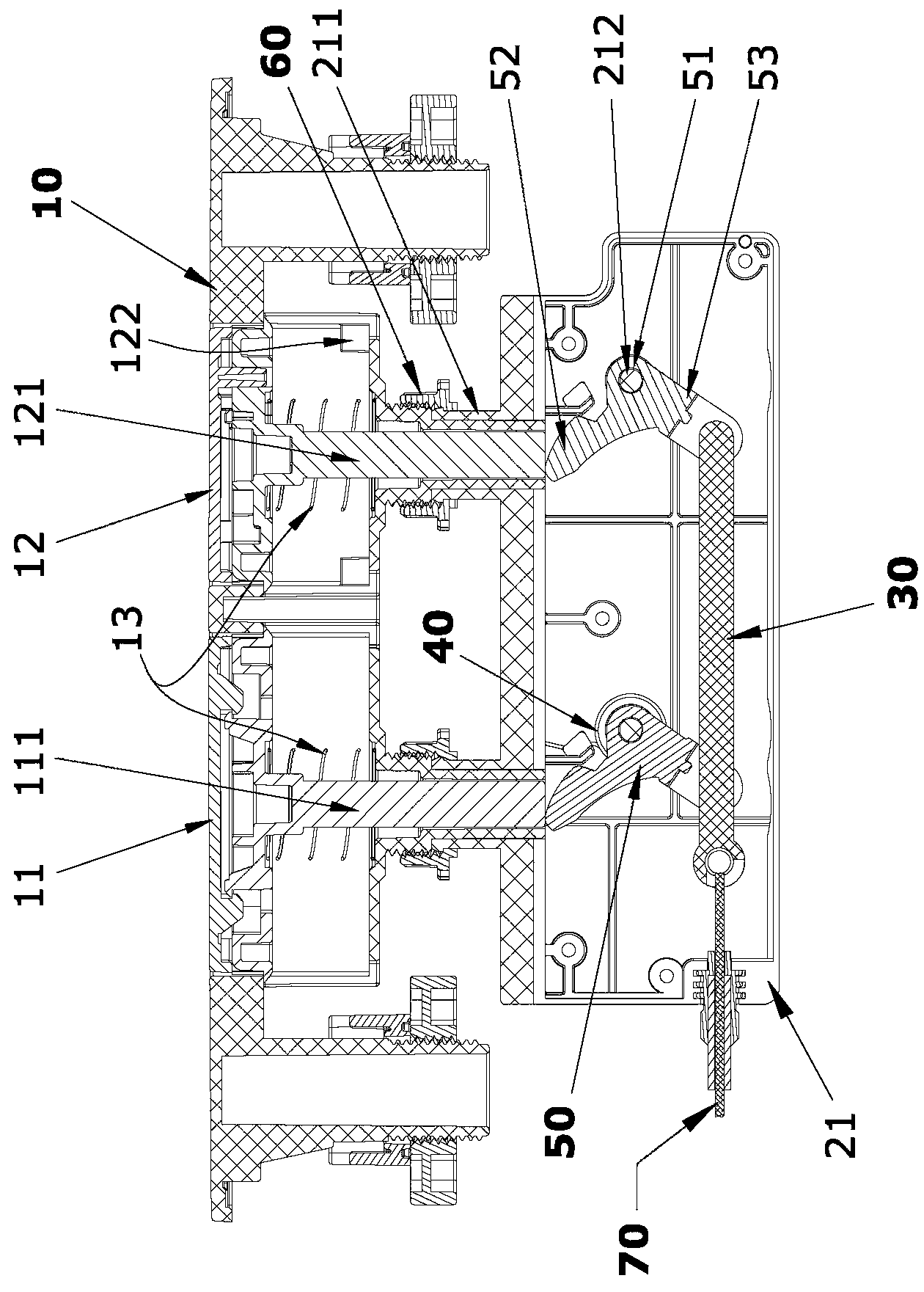

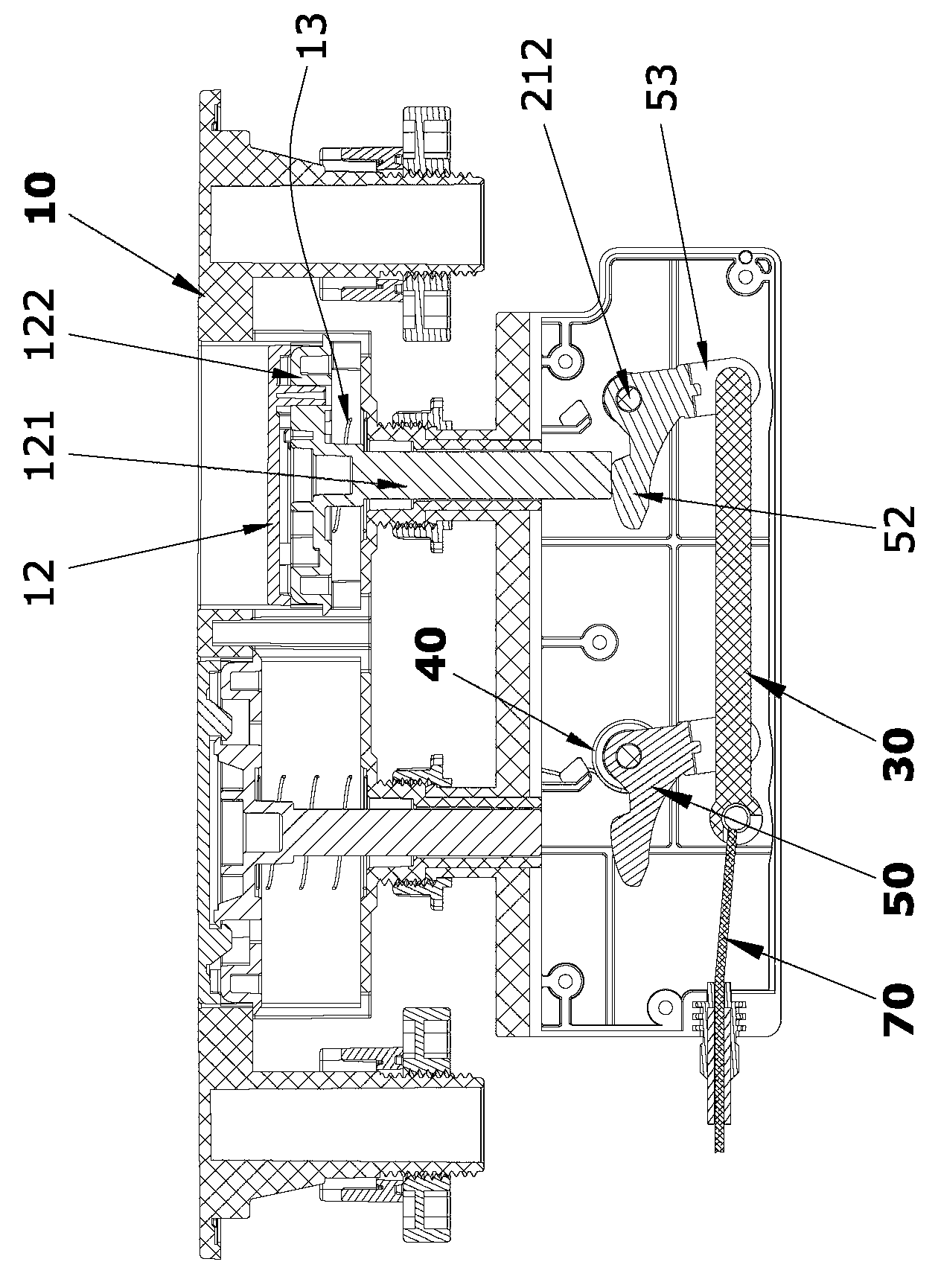

[0031] Such as figure 1 ~ Figure 4 A dual-speed drain valve wire control mechanism shown includes a button seat 10, a spring 13 is put on the full-row pressure rod 111 at the bottom of the full row of buttons 11, and is depressibly connected to the button seat 10, and the bottom of the half row of buttons 12 The half row of pressing rods 121 is also covered with a spring 13 that can be depressively connected to the button seat 10, and on the button seat 10, below the half row of buttons 12, a limit block 122 that limits the pressing stroke of the half row of buttons 12 is connected. Rows of buttons 11 and half rows of buttons 12 are arranged side by side, so that the center distance between the full row of pressing bars 111 at the bottom of the full row of buttons 11 and the half row of press...

Embodiment 2

[0034] Embodiment two (The moving part adopts a connecting rod, the toggle device adopts a turntable, and the button seat and the base shell of the wire control box are integrally formed).

[0035] Such as Figure 5 The difference between the two-speed drain valve wire control mechanism shown in the first embodiment is that the base shell 21 and the button seat 10 are integrally formed, and the sleeve 211 on the top of the base shell 21 and the connecting button seat 10 and the button seat 10 in the first embodiment are omitted. The locking nut 60 of the casing 211; other structures, working principles and implementation methods of this embodiment are the same as those of the first embodiment.

Embodiment 3

[0036] Embodiment three (The moving part adopts a slide bar, the toggle device is composed of the end face of the pressure bar and the guide slope on the slide bar, the button seat and the base shell of the wire control box are integrally formed, and the elastic part of the reset slide bar adopts a return spring).

[0037] Such as Image 6 ~ Figure 8 The difference between the two-speed drain valve wire control mechanism shown in the second embodiment is that the moving part is replaced by a connecting rod 30 with a sliding rod 32, one end of the sliding rod 32 is connected to the traction rope 70, and the other end is connected to the base shell 21. A return compression spring 41 is interposed as the return elastic member of the slide bar 32, and the two ends of the return compression spring 41 respectively resist the base shell 21 connected to the wire control box 20 and the slide bar 32 which can slide horizontally in the base shell 21; The toggling device of this e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com