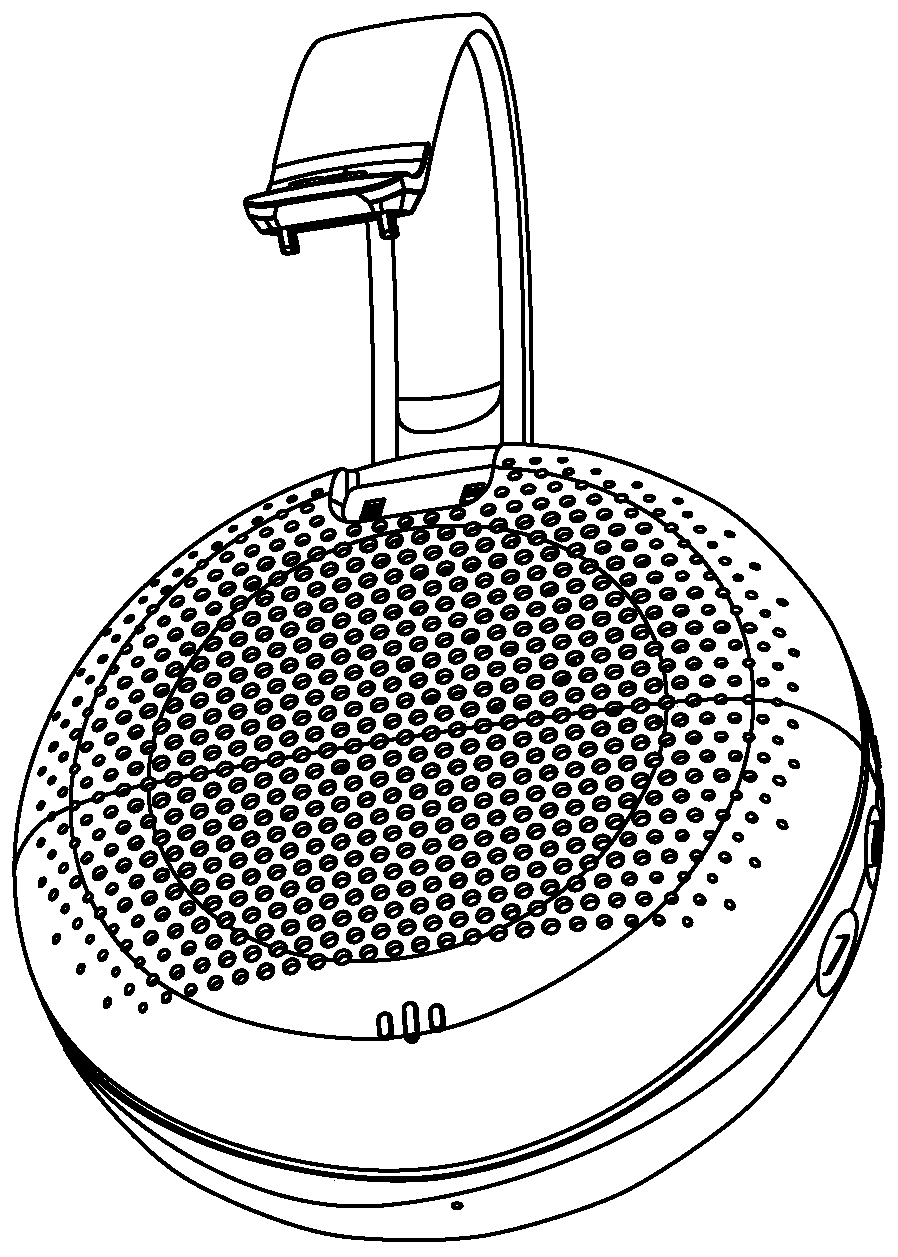

Double-layer sound outlet structure of sound box and processing method thereof

A processing method and technology for sound holes, which are applied in the direction of frequency/direction characteristic devices, etc., can solve the problems of inconvenient assembly, easy infiltration of glue and blocking of sound holes, blocking of metal mesh holes, etc., so as to achieve stable and reliable connection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

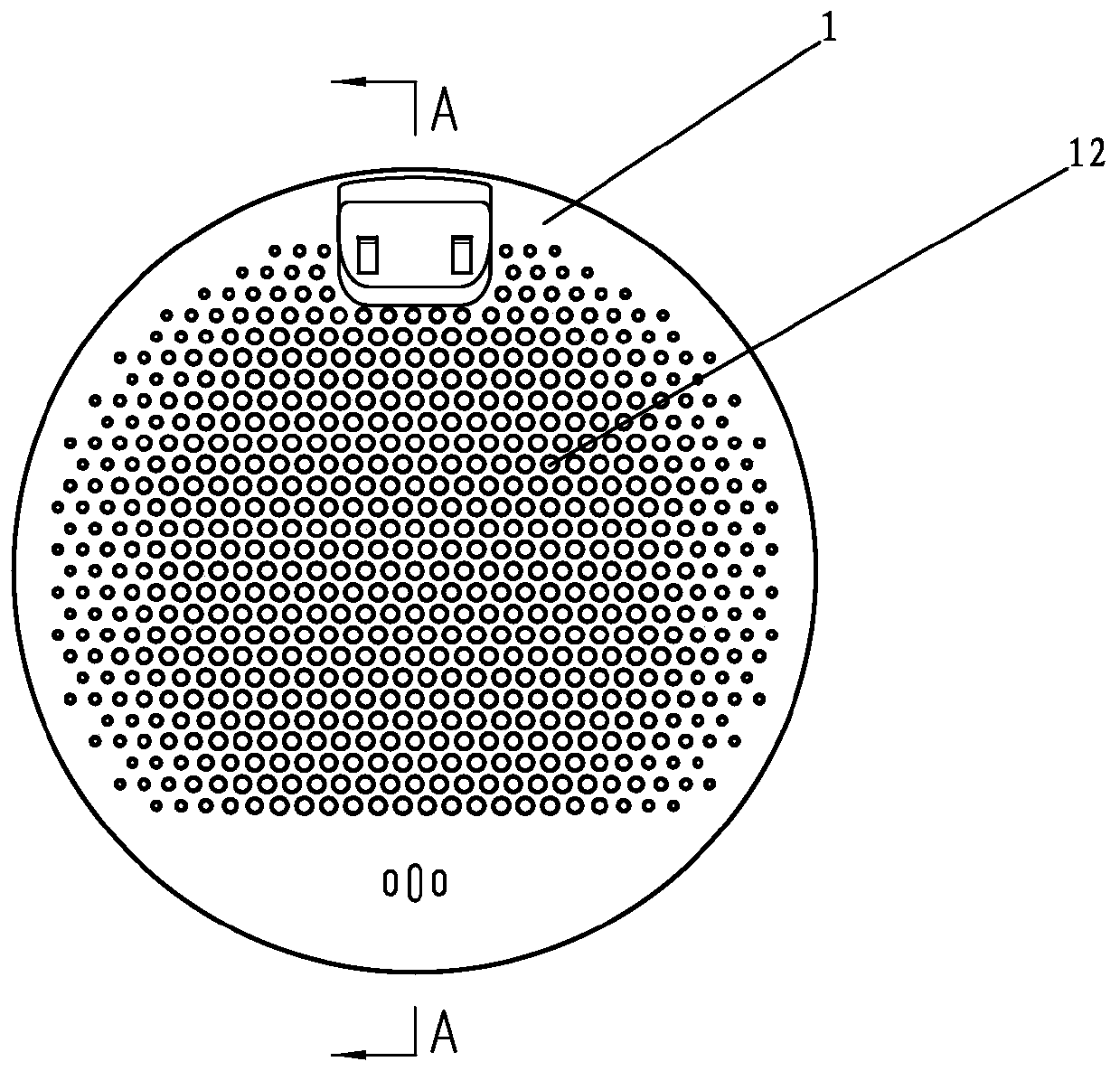

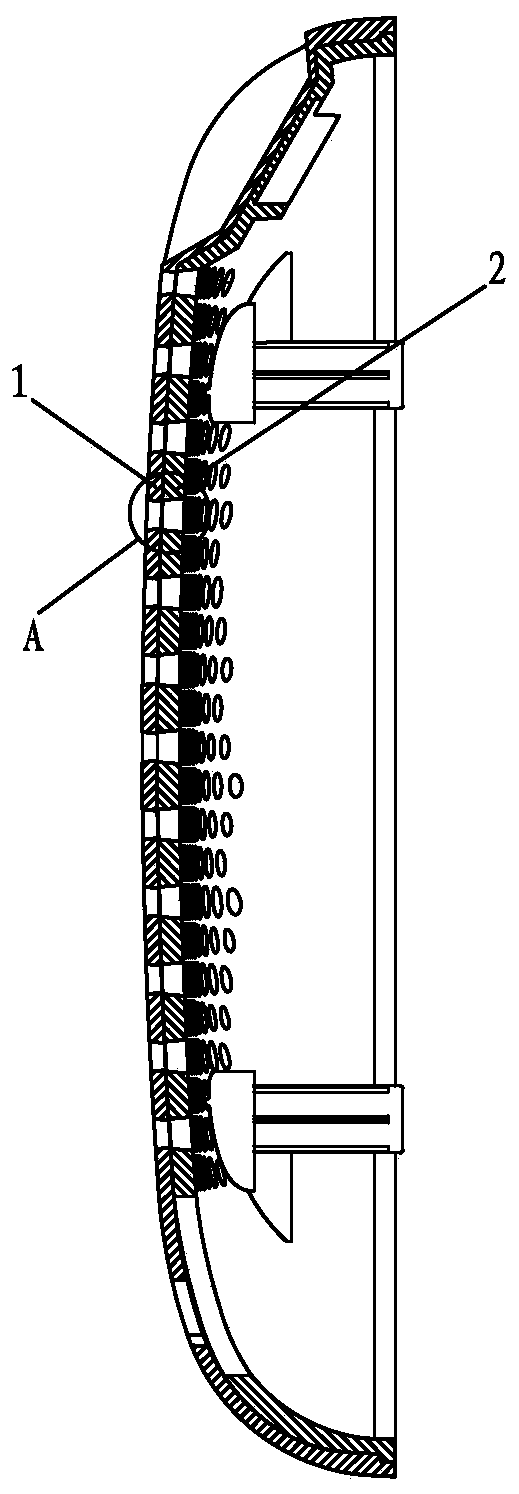

[0032] refer to Figure 2 to Figure 4 , the present embodiment relates to a double-layer sound outlet structure of a sound box, including a soft rubber layer 1 and a hard rubber layer 2 that are arranged on the outside and the inside, and the soft rubber layer 1 and the hard rubber layer 2 are fixedly connected together through an injection molding process. The soft rubber layer 1 and the hard rubber layer 2 are respectively provided with sound holes 12 corresponding to each other, and the sound hole 12 of the inner hard rubber layer 2 is larger than the corresponding sound hole 12 of the outer soft rubber layer 1 , the sound outlet hole 12 of the outer soft rubber layer 1 is set within the cross-sectional range of the corresponding sound outlet hole 12 of the inner hard rubber layer 2 . The tensile strength of the soft rubber layer 1 is greater than 10KG / N; the impact strength of the hard rubber layer 2 is greater than 15KN / M, and the fat melting is less than 15CM3 / 10Min. Op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com