Full-automatic cover screwing laser radium emission coding method

A laser laser, fully automated technology, applied in the direction of laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problem of poor feeding effect of bottle caps, unable to realize synchronous tracking of bottle caps and bottle cap transfer devices, etc., to achieve material feeding Quick and easy results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

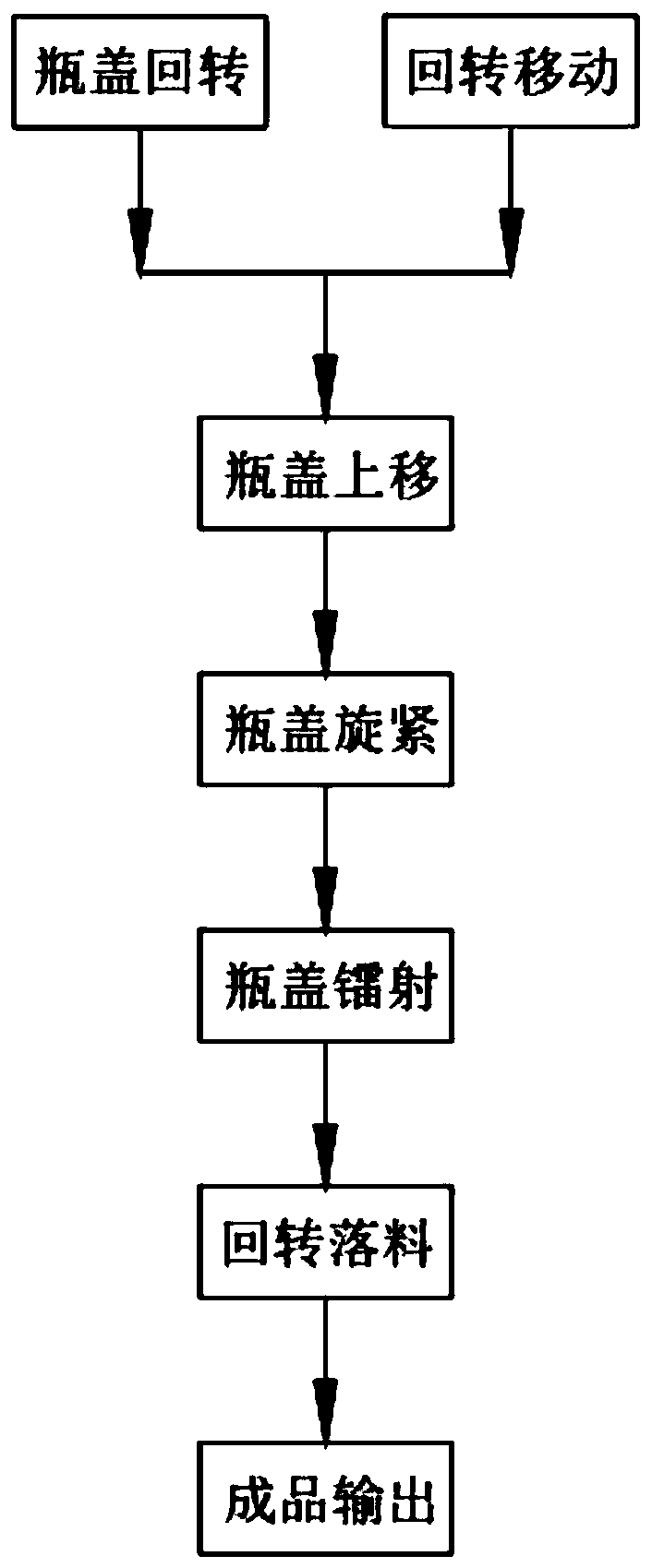

[0046] Such as figure 1 As shown, a fully automatic capping laser marking method includes the following steps:

[0047] Step 1, the bottle caps are rotated, and the bottle caps 10 that have been produced and processed are placed one by one in the feeding parts 413 that are evenly distributed on the feeding rotating belt 412, and are carried out under the rotating assembly 31 driven by the rotation of the feeding rotating assembly 41 rotary motion;

[0048] Step 2, rotary movement, the rotary motion of the rotary assembly 31 drive...

Embodiment 2

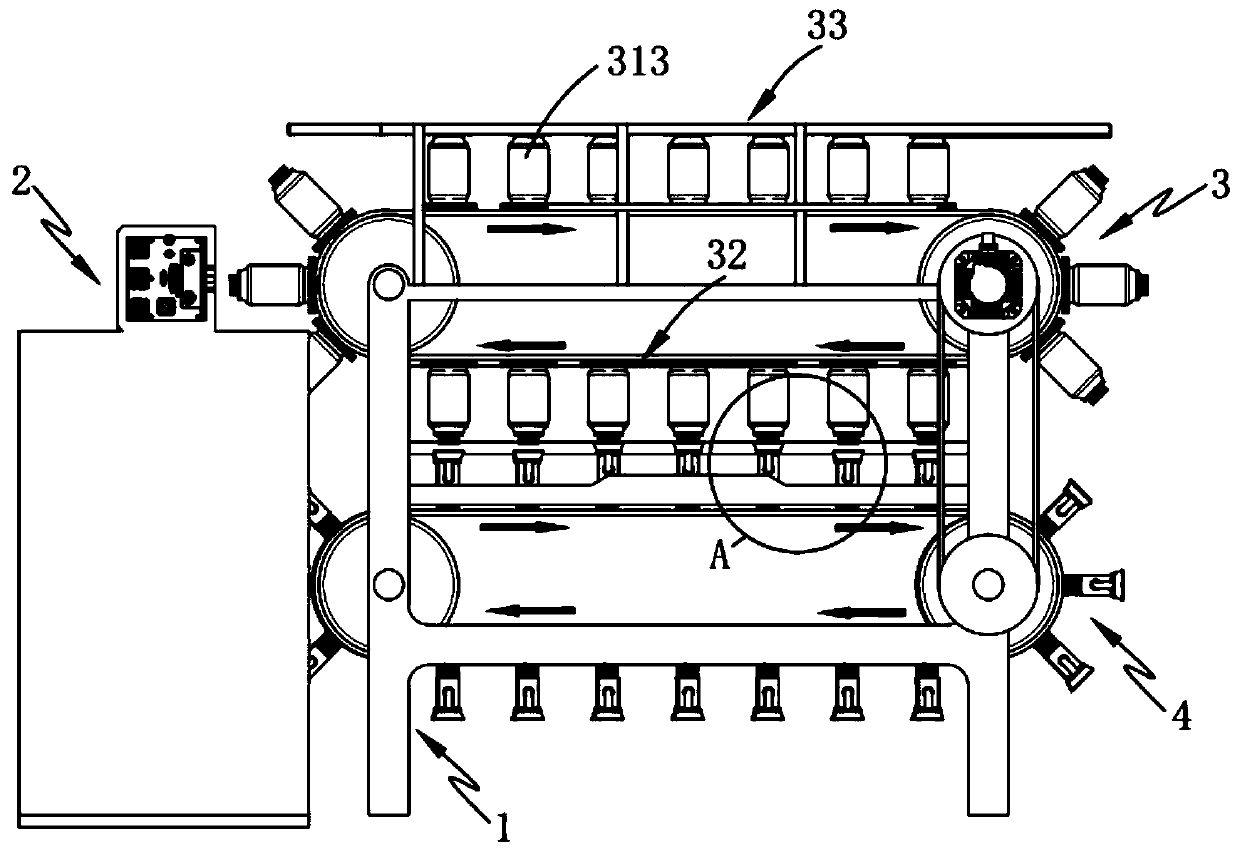

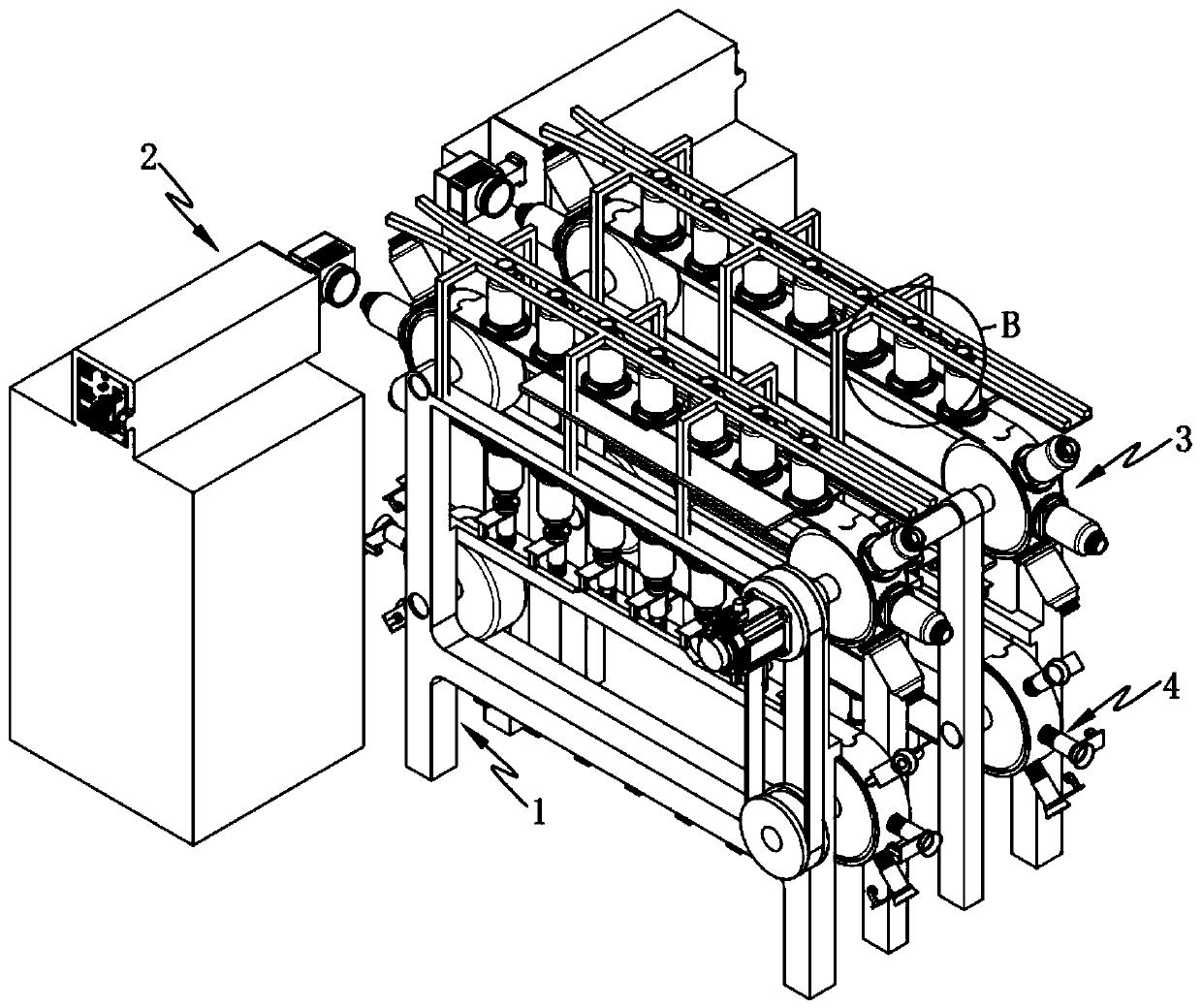

[0064] The present invention also provides an automatic bottle cap laser laser production line, such as figure 2 and 3 As shown, including bracket 1 and marking device 2, also includes:

[0065] The bottle cap transfer device 3, the bottle cap transfer device 3 is arranged on the support 1, the bottle cap transfer device 3 includes a rotary assembly 31 which is rotatably arranged on the support 1, and a rotary assembly 31 which is arranged below the rotary assembly 31. The feeding and tightening assembly 32 and the output assembly 33 arranged above the rotary assembly 31 , the rotary assembly 31 rotates through the feeding and tightening assembly 32 to screw the bottle cap 10 to be marked on the rotary assembly 31 And transfer to the marking device 2 for marking and then enter the output assembly 33 for outward output; and

[0066] A feeding device 4, the feeding device 4 is arranged on the support 1, and the feeding device 4 is located below the bottle cap transfer device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com