Large-sized curved surface revolving body heat-insulation material forming temperature control device and method

A technology of temperature control device and heat insulation material, which is applied in the field of thermal protection, can solve the problems that the large-curvature rotary structure configuration is not conducive to heat flow, the risk of resin failure due to explosion, and the failure of resin reaction, so as to avoid resin explosion reaction, The effect of avoiding resin failure at high temperature and reducing product loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

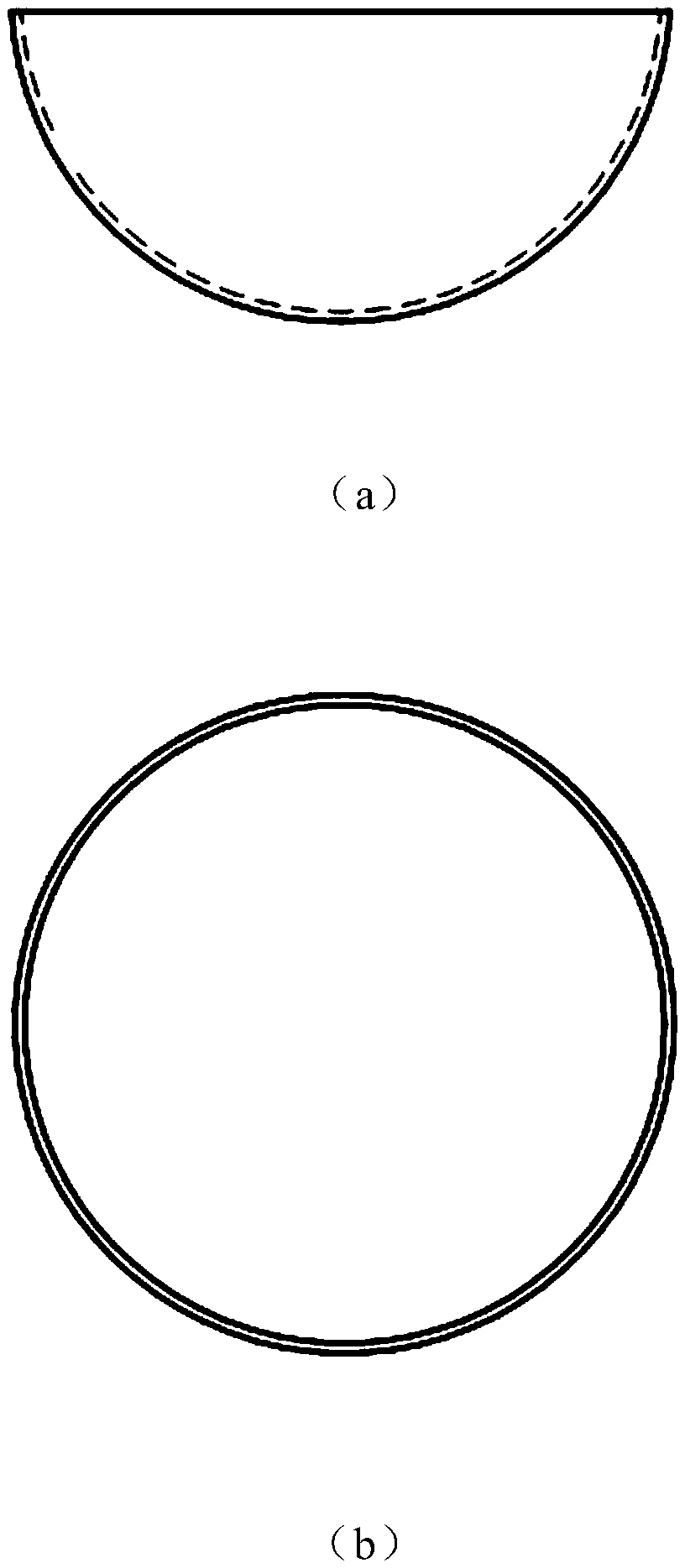

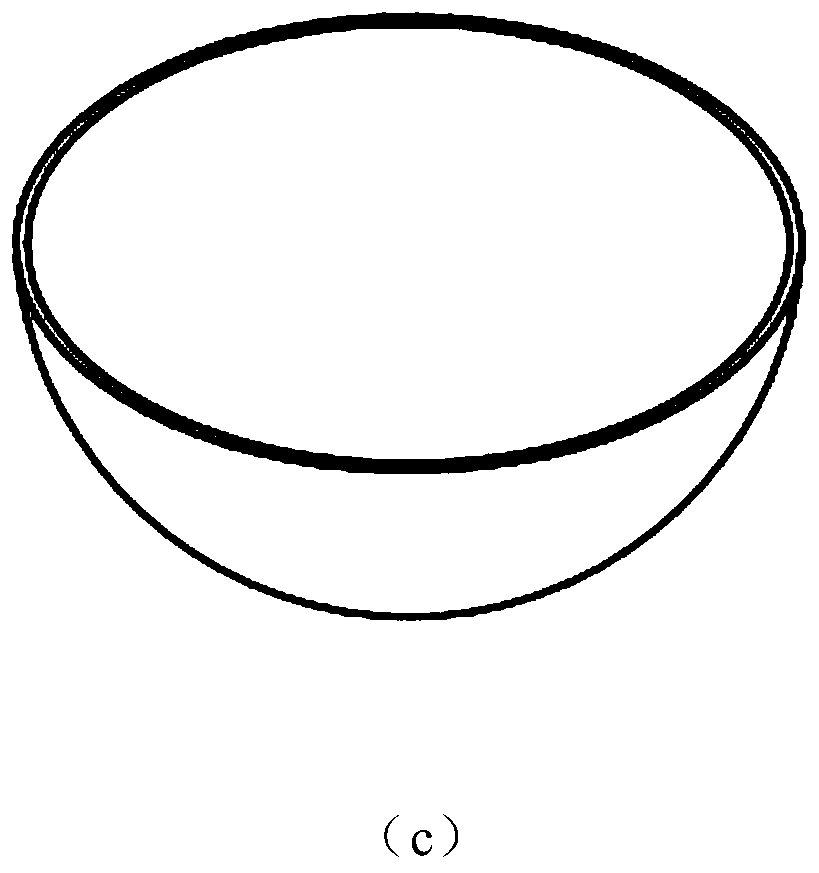

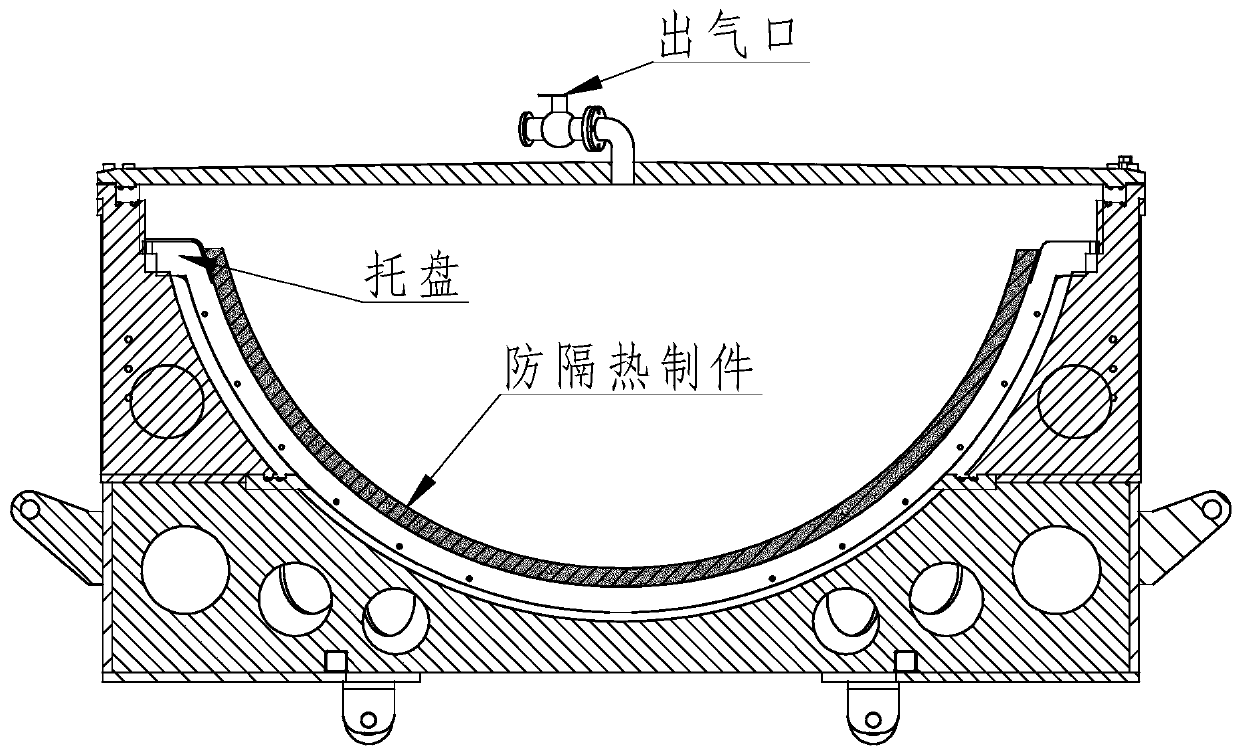

[0053] In the preparation of phenolic nano-porous anti-insulation materials with a thickness of 60mm and an in-plane area greater than 6㎡ of large size and hemispherical surface rotation structure ( figure 1 ), first, install six air inlets at the bottom of the forming tooling, and install one air outlet in the middle of the upper die cover. The workpiece is supported by a reinforced pallet, and the covered area of the workpiece is not greater than 30% of the outer surface of the workpiece. The workpiece is placed in the tooling as follows: figure 2 As shown, the distance between the workpiece and the tooling cavity is greater than 30mm. The air outlet of the forming tooling is connected to the recovery system, and the pressure gauge is connected in the middle; the air inlet is connected to the nitrogen generator, and the nitrogen generator is divided into two outputs, one output pipeline is equipped with heating equipment, and then connected to the uniformly distributed fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com