Step-by-step secondary core-pulling demolding device with transverse sliding block for injection mold

A transverse sliding block and secondary core pulling technology, applied in the field of demolding devices, can solve the problems of low efficiency, low production efficiency, high work intensity, etc., and achieve the effects of reducing cost, improving efficiency and reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

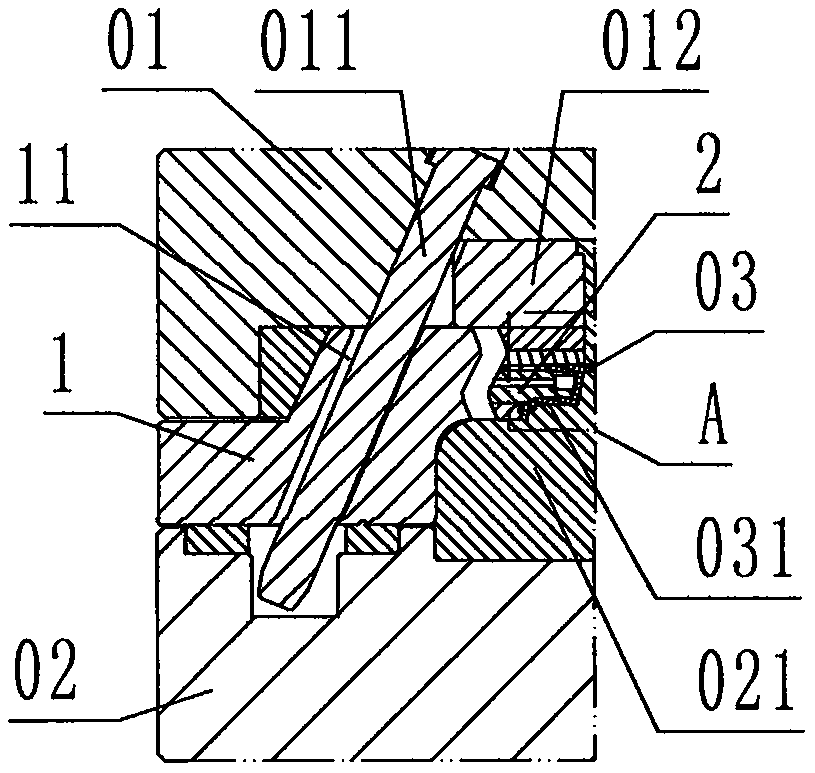

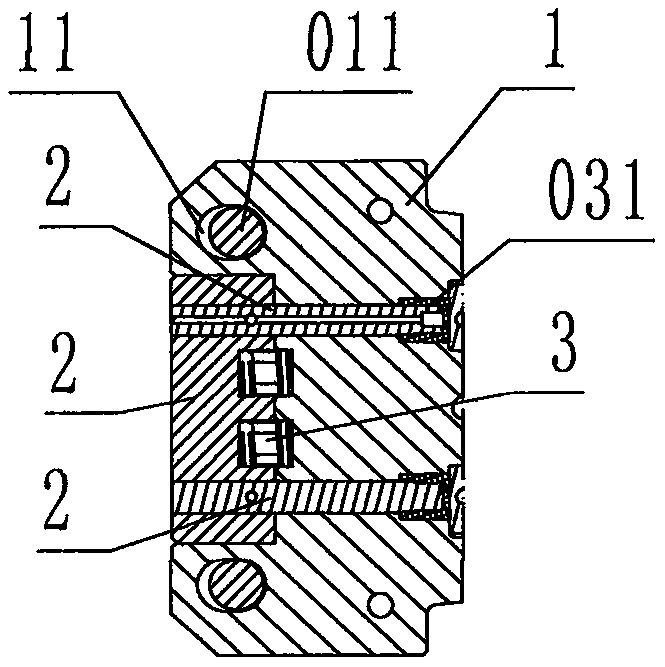

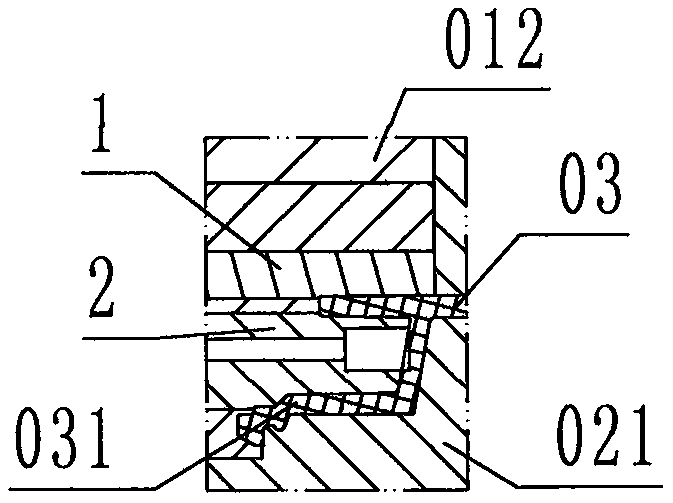

[0028] refer to Figure 1 to Figure 9 , a step-by-step secondary core-pulling demoulding device for a lateral slider of an injection mold, comprising a lateral slider 1, a first core-pulling block 2 and a spring 3, wherein: the first core-pulling block 2 is closed on the left side 1. The right side is open, rectangular ring frame-shaped block steel member, the left side of the left frame wall of the core block 2 is an inclined plane inclined from top to bottom; The surface corresponding to the large covering force structure 031 of the product 03 is respectively called the drawing surface;

[0029] The transverse slider 1 is a wedge-shaped steel member, the left side of the transverse slider 1 is a slope inclined from top to bottom to the left, and the right side of the transverse slider 1 is provided with a corresponding The shape surface is called the block surface, and the top of the horizontal slider 1 is provided with a groove corresponding to the shape of the first core-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com