Bottom plate for fixing sand painting and manufacturing method and using method of bottom plate

A production method and sand painting technology, applied in the field of art tools, can solve the problems of complex operation, high requirements for use conditions, and heavy materials, and achieve the effects of high chemical stability, chemical stability and waterproofing, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings, but the present invention is not limited thereto.

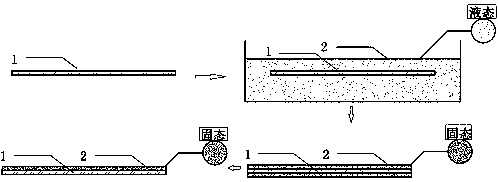

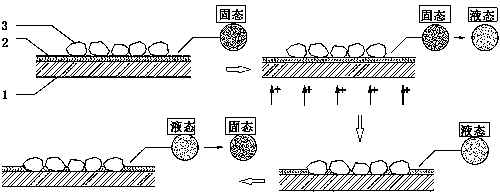

[0022] refer to Figure 1 to Figure 3

[0023] A bottom plate for fixing sand paintings, comprising a metal plate material 1, on which is attached a layer of paraffin wax layer 2 which can fix sand pictures after being heated.

[0024] In this embodiment, the metal plate material is steel, aluminum alloy or stainless steel with good thermal conductivity, and the paraffin 2 is Quan Refining Industry No. 58 white paraffin.

[0025] Preferably, the metal plate material 1 is an aluminum plate with a size of 25cm*40cm*0.1cm.

[0026] A method for making a bottom plate for sand painting, the steps are as follows:

[0027] (1) Take a piece of cut sheet metal material;

[0028] (2) Immerse the metal plate material i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com