Train vacuum-maintenance-type sanitation system

A vacuum maintenance, train technology, applied in sanitary equipment, railway car body parts, transportation and packaging, etc., can solve the problem of low utilization rate, reduce the possibility of failure, reduce the possibility of fouling, and reduce the entry of impurities the effect of the possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

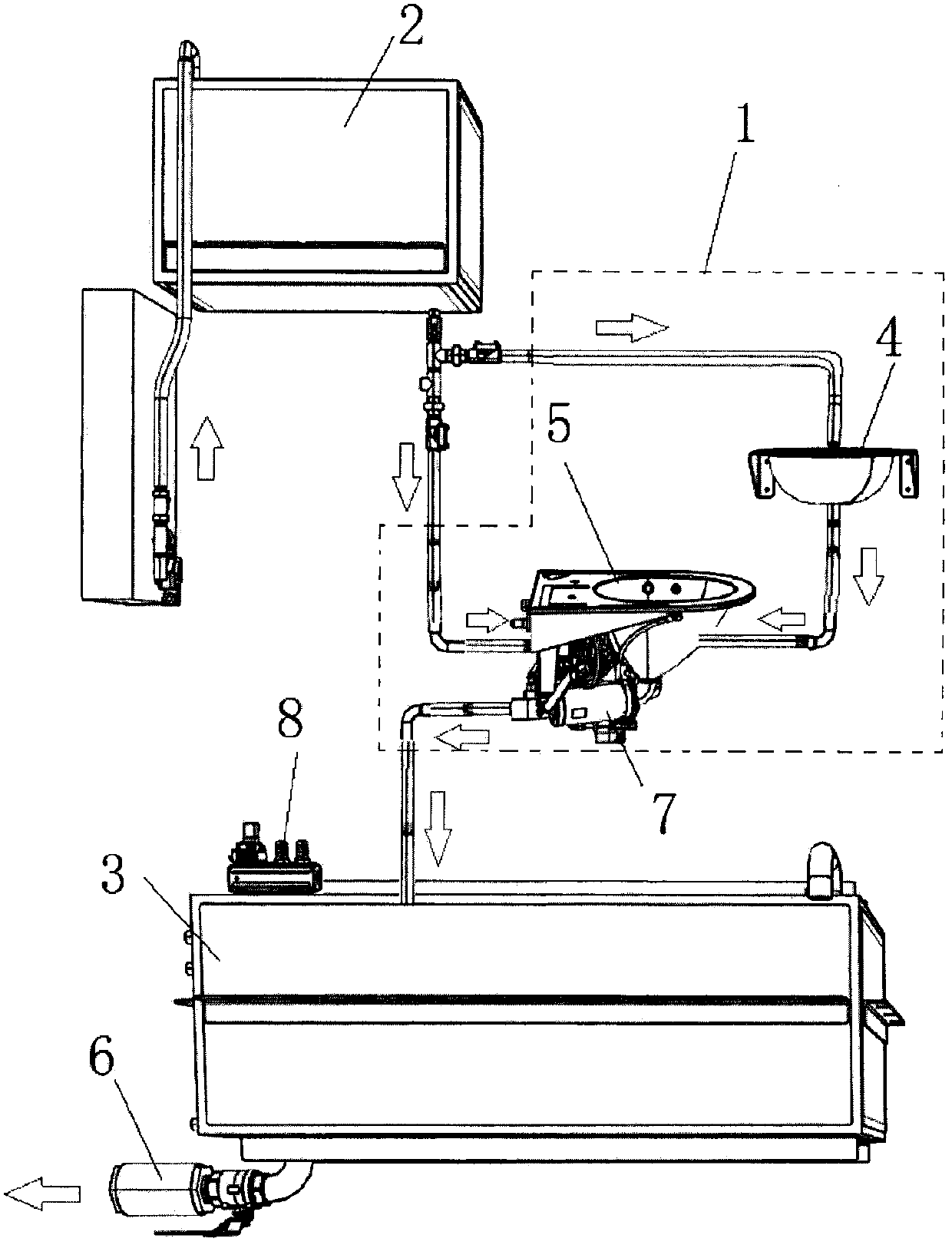

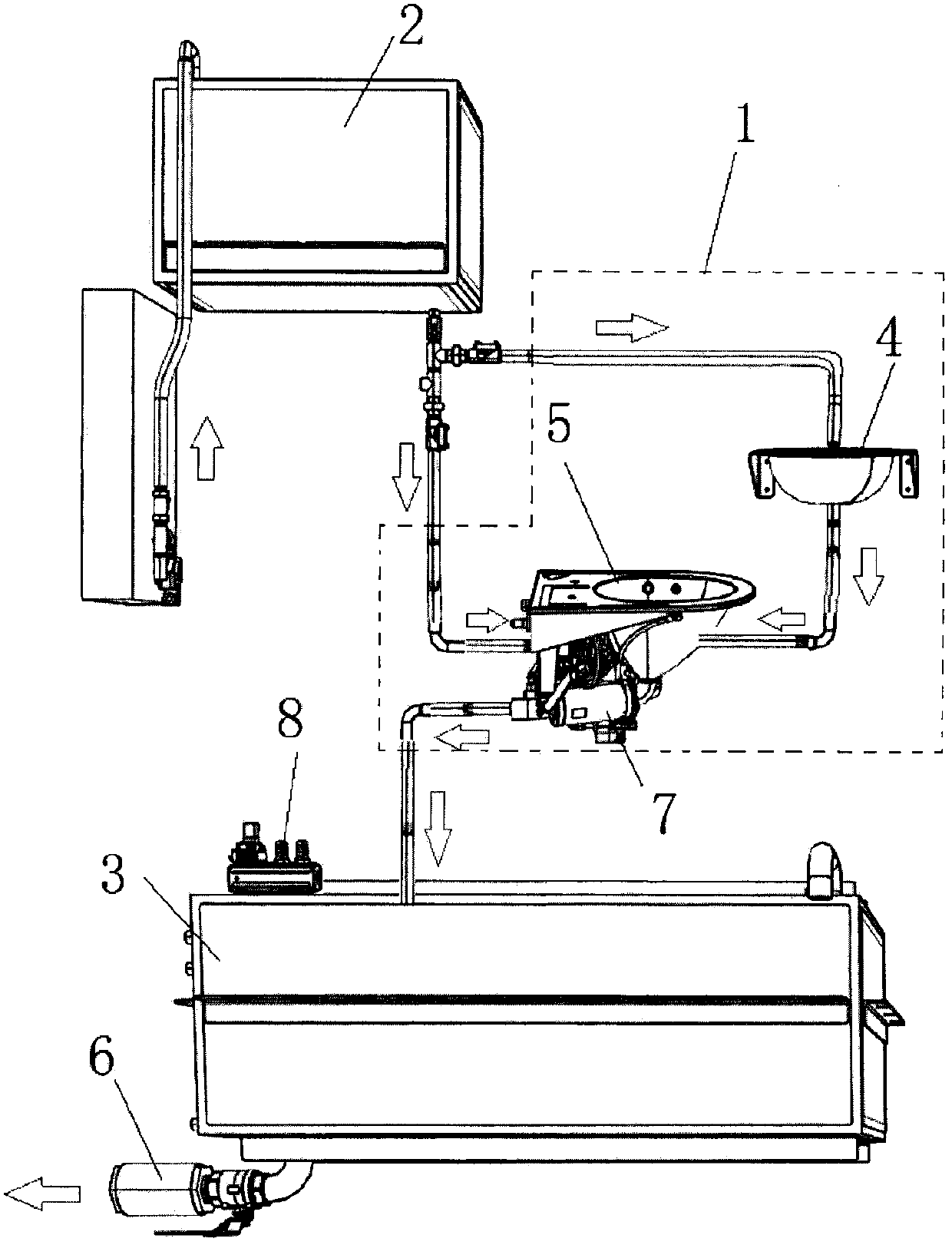

[0023] Below in conjunction with accompanying drawing, the specific embodiment of train modular toilet of the present invention is described in detail.

[0024] See attached figure 1 , train vacuum maintenance sanitation system, including toilet 1, clean water tank 2, sewage tank 3, clean water tank 2 is located in the train body, fixed above the toilet 1, enters toilet 1 for water supply through pipelines, and sewage tank 3 is located at the lower part of the train body , through the pipeline to receive toilet 1 sewage, clean water tank 2 is connected to the water outlet tap of washbasin 4 in toilet 1 and the water storage tank of toilet 5 respectively, and the drainpipe of washbasin 4 is also connected to the water storage tank of toilet 5, toilet The sewage pipe of 5 is connected to the sewage tank 3, the waste water outlet 6 is set under the sewage tank 3, and the secondary jet tube vacuum generator 7 is set between the toilet 5 and the sewage pipe, and the flushing vacuum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com