Metallic solution transfer device

A transfer device, metal solution technology, applied in the direction of lifting device, lifting frame, non-detachable cover/cover, etc., can solve problems such as cylinder bursting, and achieve the effect of avoiding bursting and convenient feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

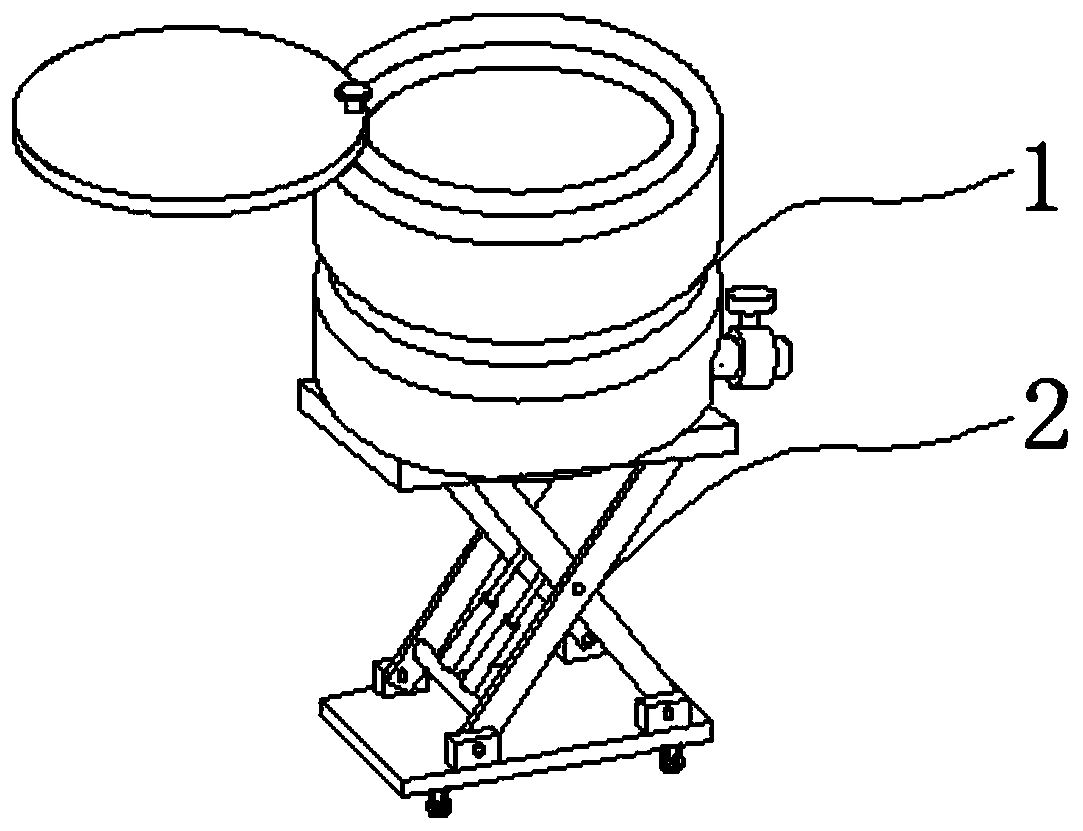

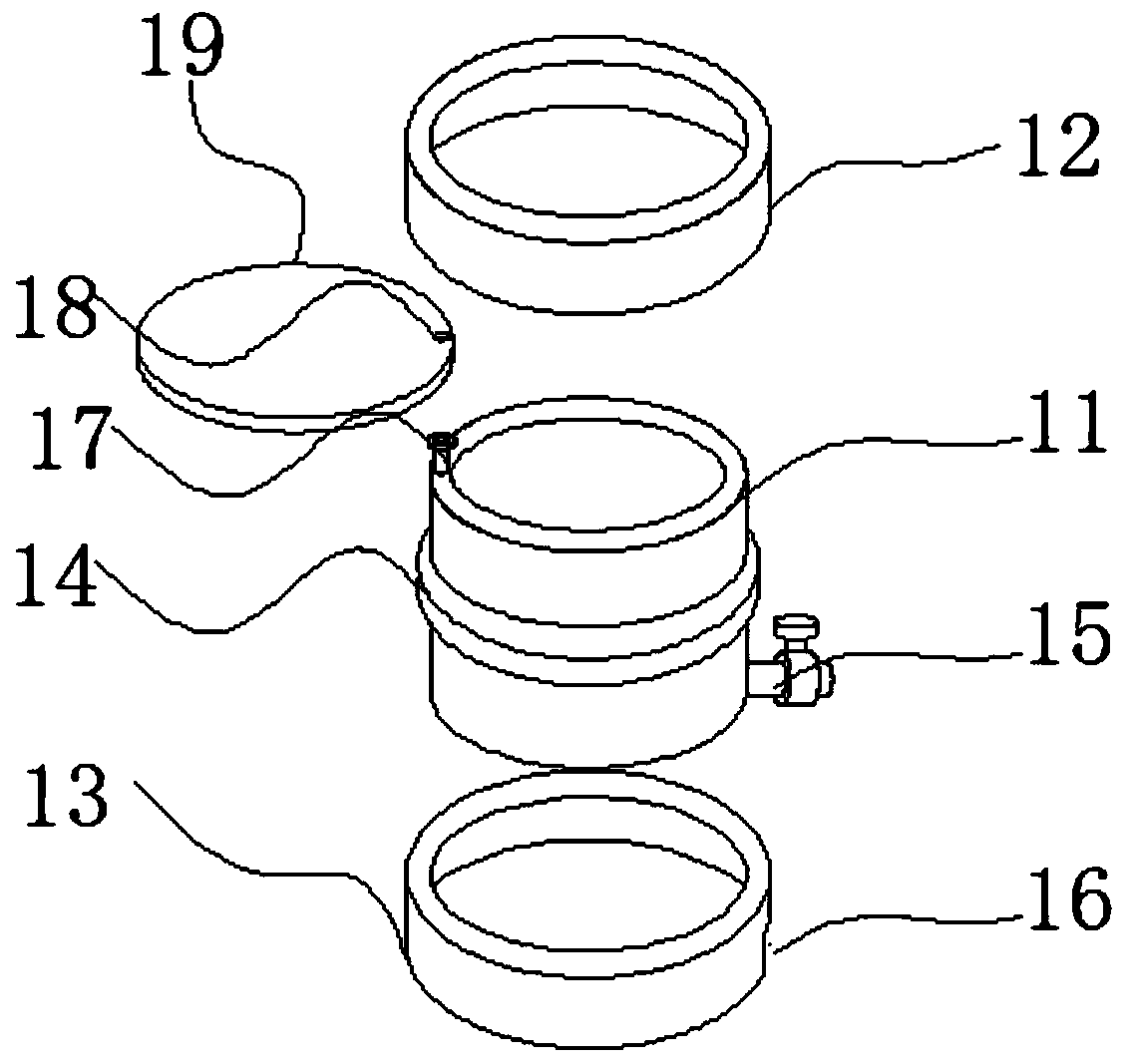

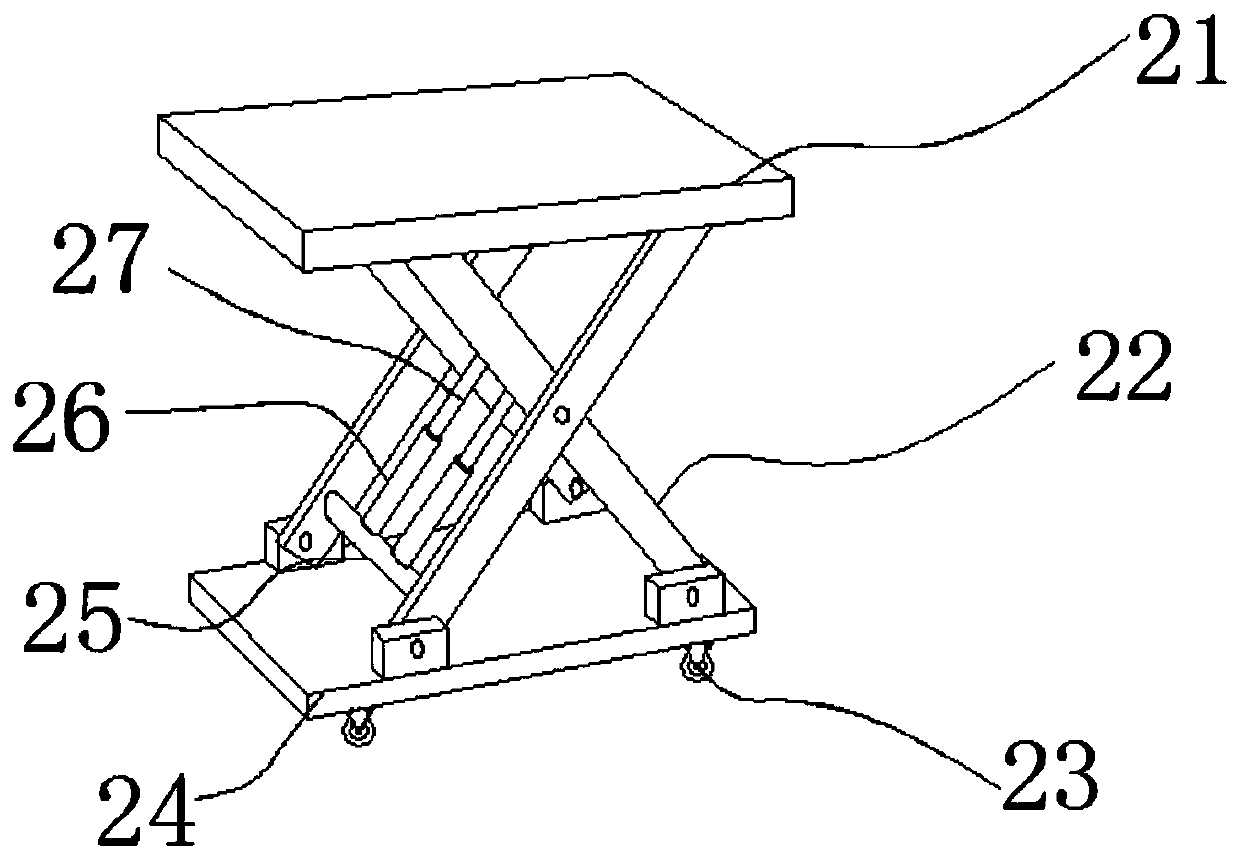

[0021] Embodiment 1, with reference to figure 1 and 2 As shown, a metal solution transfer device includes a storage mechanism 1. The storage mechanism 1 includes a storage cylinder 11, an upper explosion-proof jacket 12, a lower explosion-proof jacket 13 and an upper cover 19. The storage cylinder 11 is used to store the metal solution. The storage cylinder 11 One side of the upper surface is fixed with a lower guide column 17, the guide column 17 is used to install the upper cover 19, the upper surface side of the upper cover 19 is provided with a through hole 18, and the guide column 17 passes through the through hole 18, and the upper cover 19 can be installed Rotate on the guide column 17, so as to realize the opening and closing of the upper cover 19;

[0022] The middle part of the storage cylinder 11 is provided with an expansion joint 14. The expansion joint 14 can compensate the pressure generated by the thermal expansion of the storage cylinder 11 on the inner wall ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap