A transmission mechanism for parking equipment

A technology of transmission mechanism and parking equipment, which is applied in the direction of buildings, building types, buildings, etc. where cars are parked. It can solve the problems of high welding cost and many materials, and achieve enhanced force effect, reduced torque, and reduced force. required effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

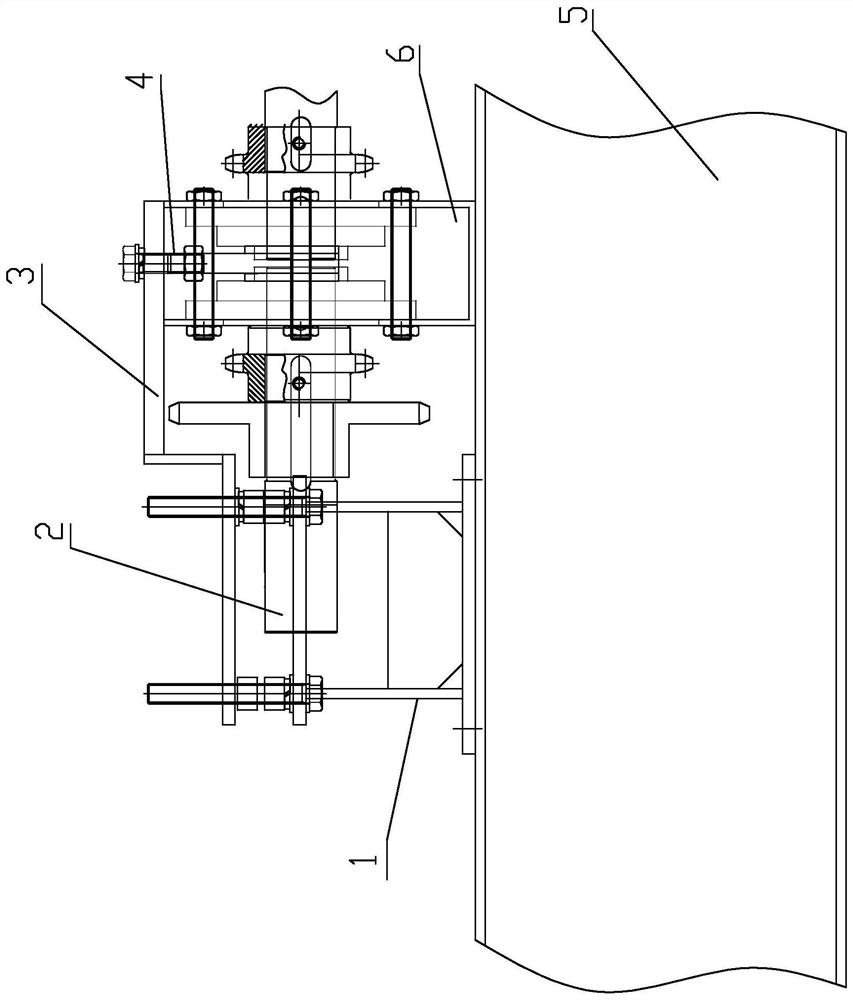

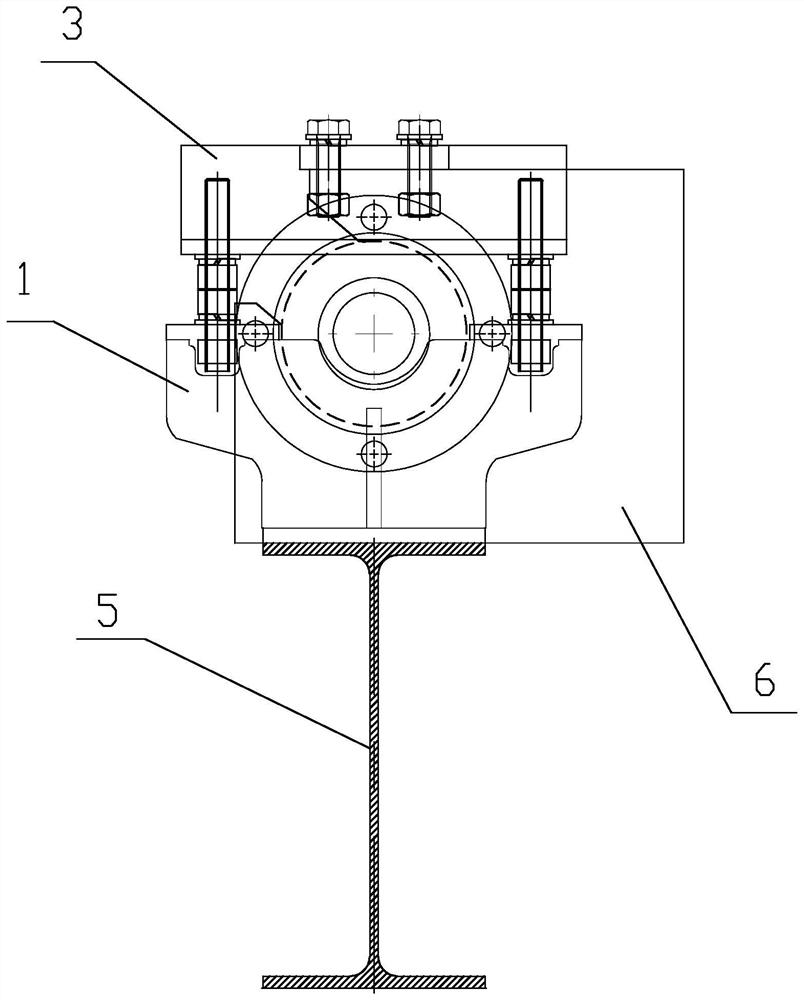

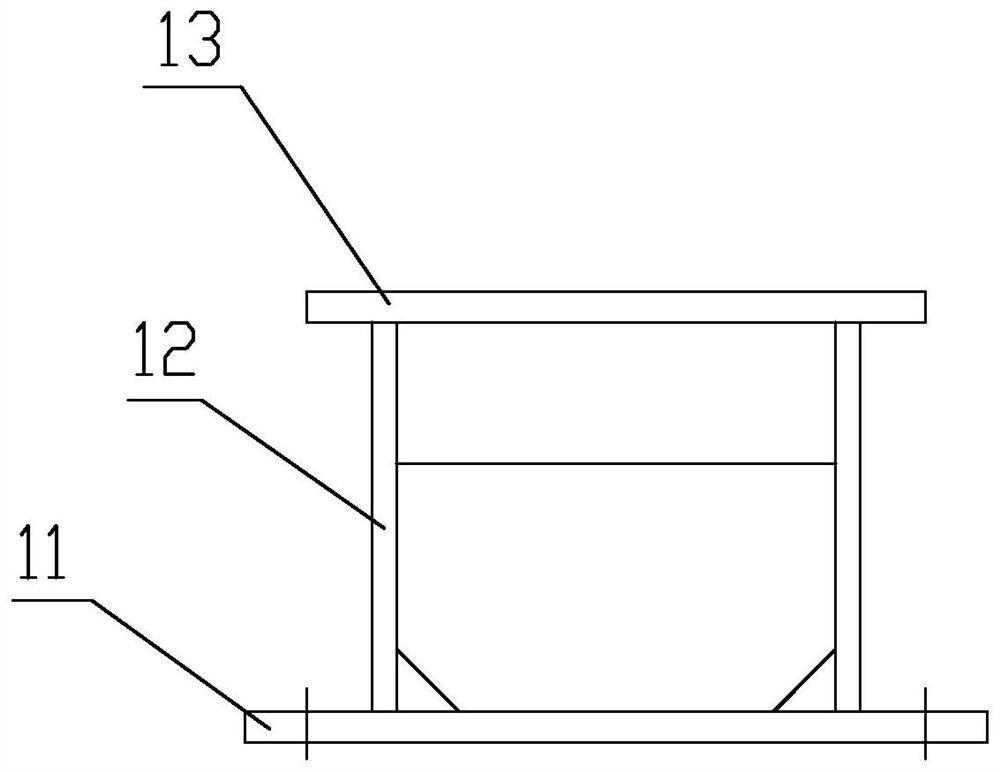

[0026] refer to Figure 1 to Figure 9 , the present invention is a transmission mechanism for parking equipment, comprising a rear beam 5, a longitudinal beam 6 mounted on the rear beam 5, a motor base 1 fixed on the rear beam 5, a transmission shaft 2 mounted on the motor base 1 and a The connection seat 3 above the transmission shaft 2, the motor seat 1 is arranged on the side of the longitudinal beam 6, one end of the transmission shaft 2 is inserted inside the longitudinal beam 6, one end of the connection seat 3 is connected with the motor seat 1, and the connection seat 3 The other end is lapped on the top of the longitudinal beam 6 .

[0027] The transmission mechanism used in this parking equipment, the motor base 1 is overlapped with the longitudinal beam 6 through the connection base 3, so that the pressure part of the motor pressed on the motor base 1 is transmitted to the longitudinal beam 6, which reduces the force requirement of the motor base 1 , there is no ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com