Method for learning at least one pump feature of pump of feed module of scr catalyst system

A technology of conveying modules and catalytic converters, applied in general control systems, control/regulation systems, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

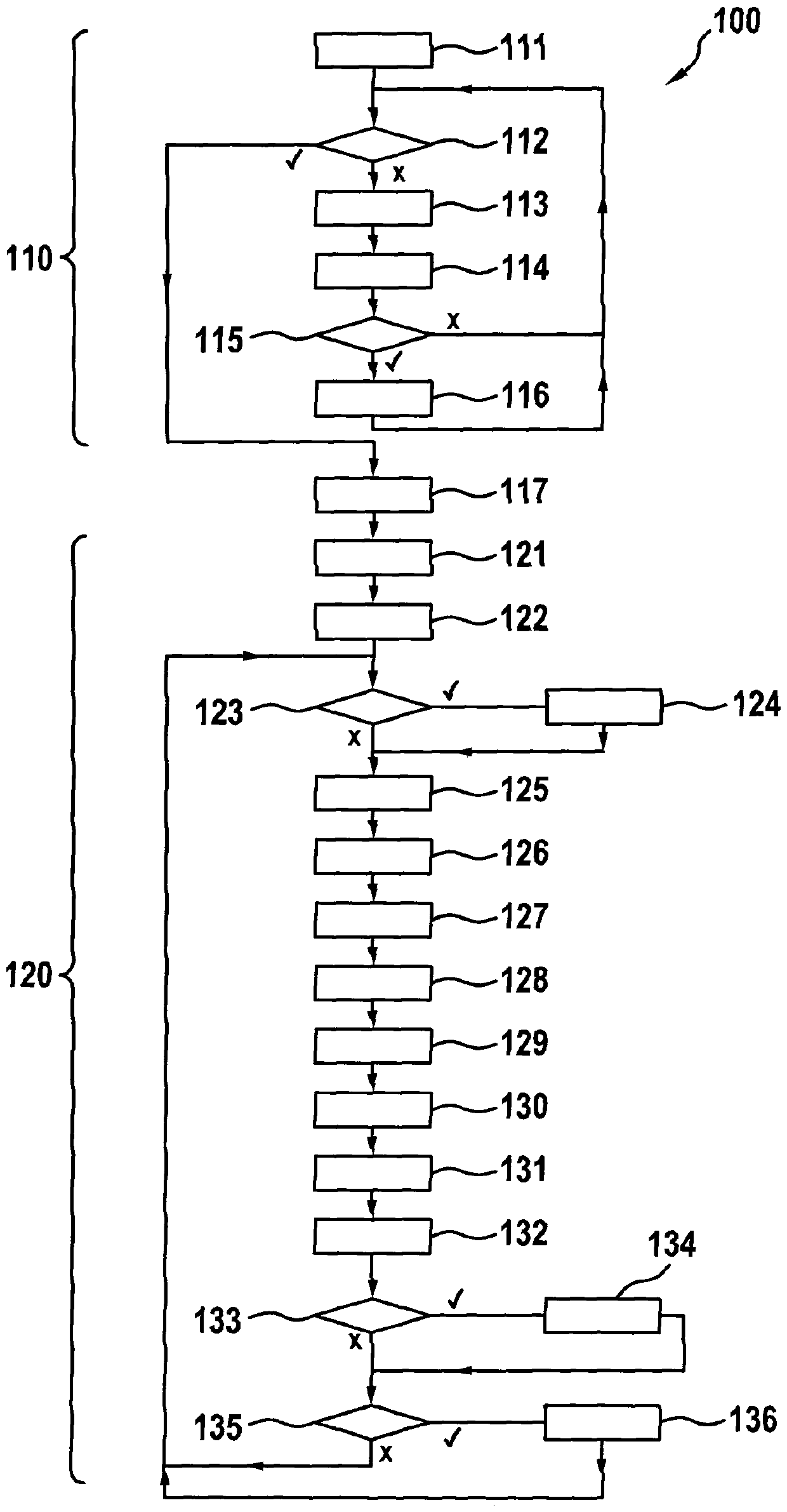

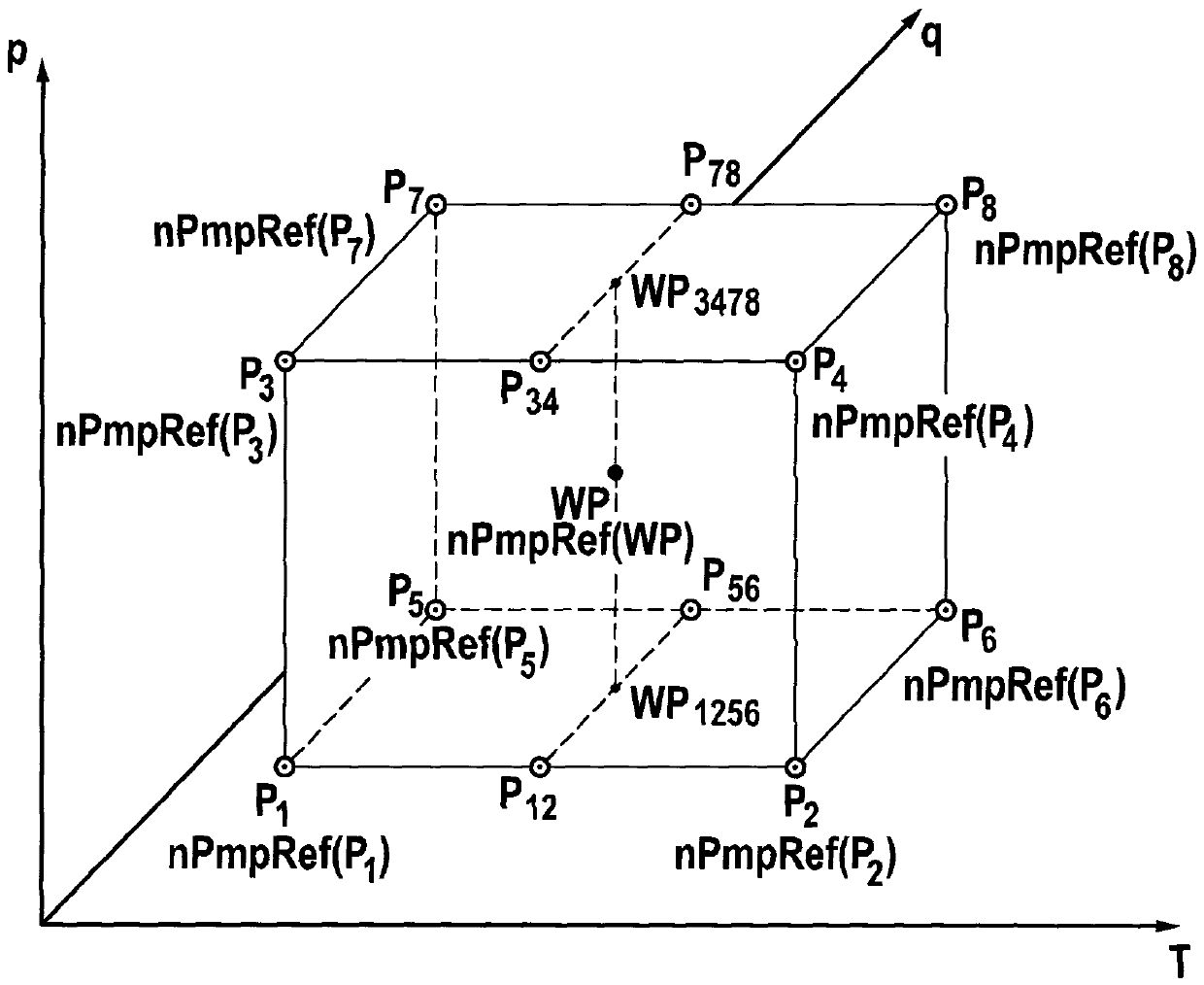

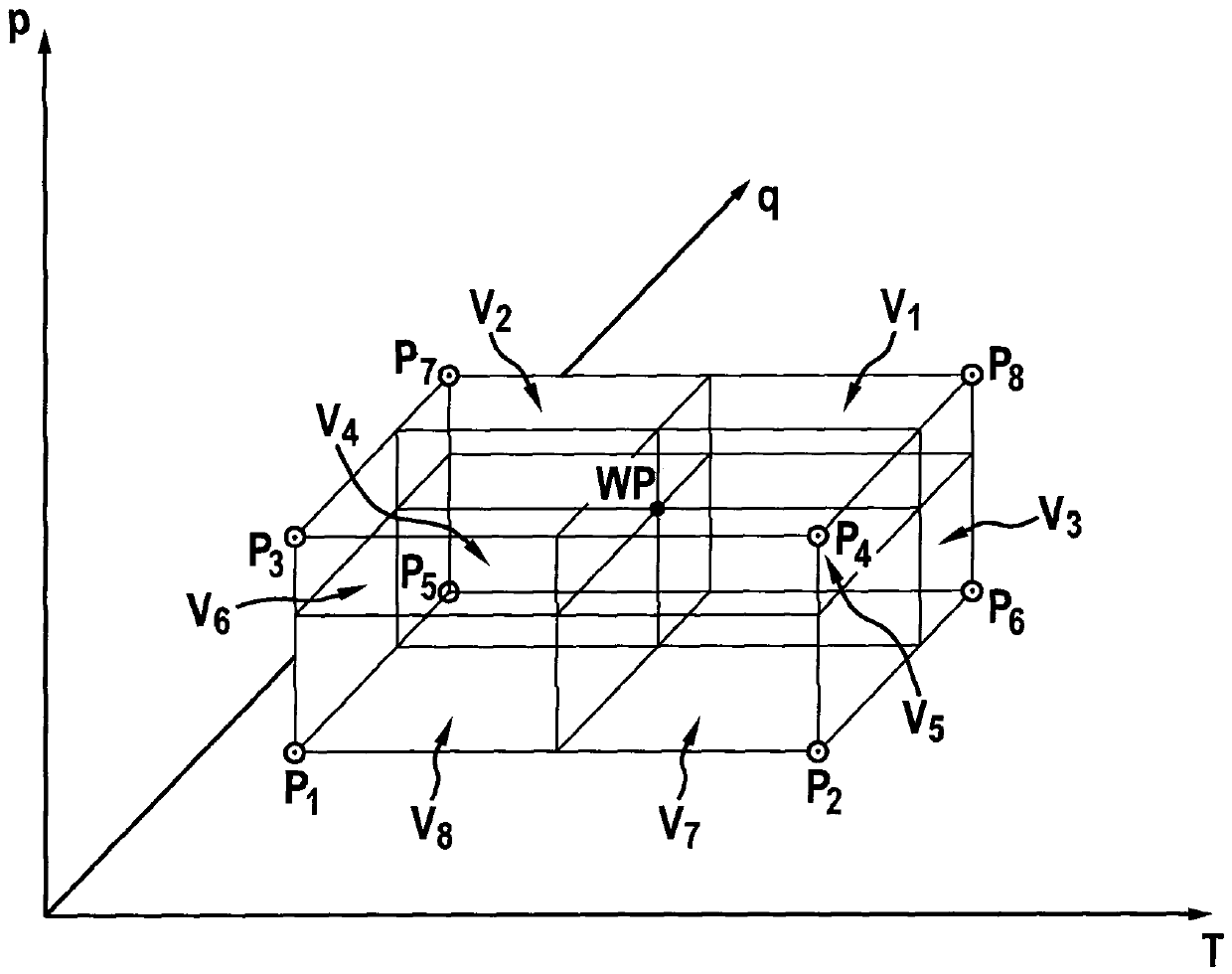

[0058] exist figure 1 3 shows an SCR catalytic converter system 10 with a metering device for metering an aqueous urea solution (HWL) 12 into the exhaust system 10 of an internal combustion engine 14 (only indicated) of a motor vehicle. By means of selective catalytic reduction (SCR), the SCR catalyst system 10 is used in a manner known per se for reducing nitrogen oxides in the exhaust gas of the internal combustion engine 1 . For the reduction, HWL 12 as reducing agent is injected via metering valve 16 of metering module 17 into exhaust gas train 18 upstream of SCR catalyst 20 and downstream of oxidation catalyst 22 .

[0059] The HWL 12 is stored in a storage tank 24 having a liquid level sensor 26 and a temperature sensor 28 which are respectively connected to a controller 29 . The metering valve 16 of the metering module 17 is supplied with HWL 12 from the storage tank 24 by means of the delivery module 30 .

[0060] The delivery module 30 has a delivery pump 32 which r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com