A single particle sensitive gas sensor and its preparation method and application

A gas sensor and sensor technology, applied in the direction of instruments, scientific instruments, measuring devices, etc., can solve the problems of semiconductor material crystal structure damage, response recovery time as high as several to tens of minutes, complex operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

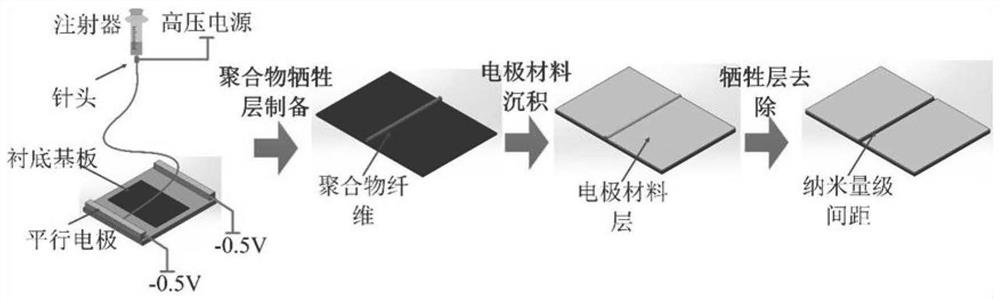

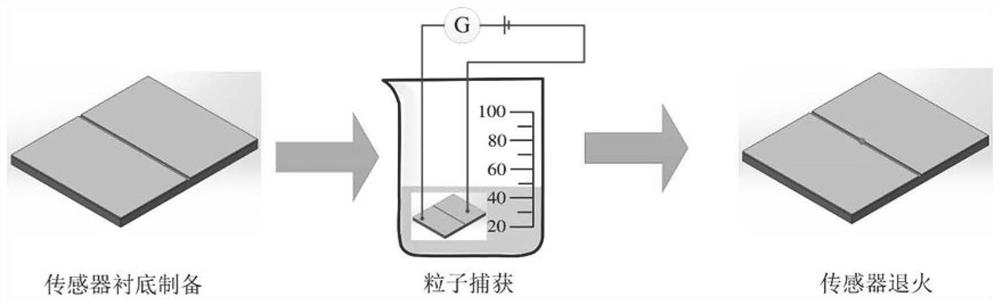

[0030] The invention provides a method for preparing a single particle sensitive gas sensor, comprising the following steps (such as figure 2 shown):

[0031] Provide the sensor substrate;

[0032] Depositing a single particle on the surface of the sensor substrate by a single particle capture method to form a single particle sensitive layer to obtain a single particle sensitive gas sensor precursor;

[0033] The single particle sensitive gas sensor precursor is annealed to obtain a single particle sensitive gas sensor.

[0034] In the present invention, unless otherwise specified, all raw materials are commercially available products well known to those skilled in the art.

[0035] The present invention provides a sensor substrate. In the present invention, the preparation method of the sensor substrate preferably includes the following steps:

[0036] After depositing the polymer fiber sacrificial layer and the electrode material layer sequentially on the sensor substra...

Embodiment 1

[0061] Mix 0.8 g of polyvinylpyrrolidone and 10 mL of ethanol, and stir in a magnetic stirrer until a uniform solution is formed to obtain an electrospinning solution;

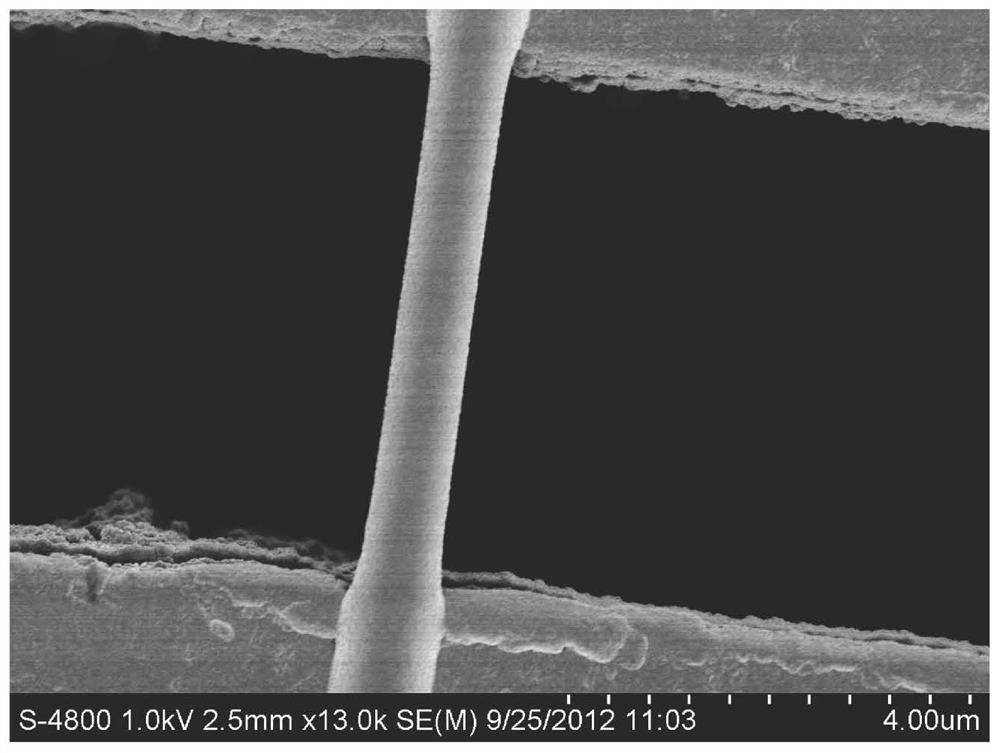

[0062] The electrospinning solution was placed in a syringe, and an orderly arranged polyvinylpyrrolidone fiber sacrificial layer was deposited on the nitrided silicon wafer by an electric field-assisted ordered electrospinning method (conditions of the electric field-assisted ordered electrospinning method : the distance between the needle of the syringe and the silicon chip is 10cm, and the voltage is 11kV; the liquid supply flow rate of the syringe is 0.3mL / h; the parallel electrode voltage of the electric field is 0.5kV, and the distance between the parallel electrodes is 1cm);

[0063] Using magnetron sputtering to sequentially deposit the underlying metal tantalum (5nm in thickness) and gold (50nm in thickness) to form an electrode material layer;

[0064] Place the above-mentioned sensor substrate depos...

Embodiment 2

[0069] Mix 0.6 g of polyvinyl alcohol and 10 mL of ethanol, and stir in a magnetic stirrer until a uniform solution is formed to obtain an electrospinning solution;

[0070] The electrospinning solution was placed in a syringe, and an orderly arranged polyvinyl alcohol fiber sacrificial layer was deposited on the nitrided silicon wafer by an electric field-assisted ordered electrospinning method (conditions of the electric field-assisted ordered electrospinning method : the distance between the needle of the syringe and the silicon wafer is 13cm, and the voltage is 10.5kV; the liquid supply flow rate of the syringe is 0.2mL / h; the parallel electrode voltage of the electric field is -0.1kV, and the distance between the parallel electrodes is 0.5cm);

[0071] The underlying metal tantalum (thickness is 10nm) and platinum (thickness is 100nm) are sequentially deposited by magnetron sputtering;

[0072] Place the above-mentioned sensor substrate deposited with the polyvinyl alcoho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com