Wireless communication-based modularized automatic cable checking device

A wireless communication and modularization technology, applied in the direction of measuring devices, instruments, measuring electronics, etc., can solve problems such as difficulty in meeting calibration requirements, non-one-to-one correspondence between output signals and collection results, and inconsistent number of pins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086] according to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 Describe this embodiment:

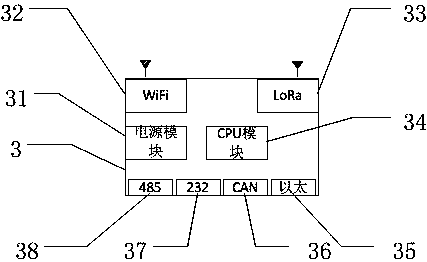

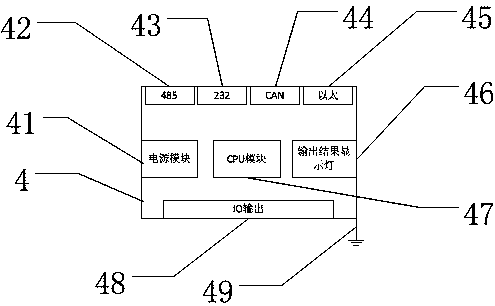

[0087] In specific embodiment 1, the modularized automatic calibration device based on wireless communication provided by the present invention, such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the automatic calibration device includes a terminal display module 1, a wireless master module 2, a plurality of wireless slave modules 3, a plurality of output modules 4 and a plurality of acquisition modules 5.

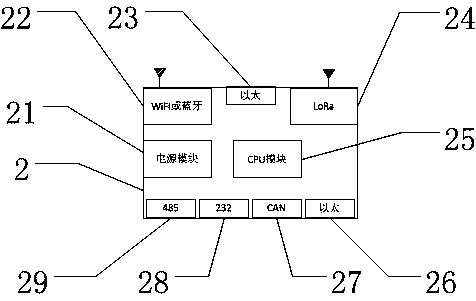

[0088] In specific embodiment 1, such as figure 1 As shown, the wireless main module 2 provided by the present invention includes a power supply module 21, a WiFi or Bluetooth module 22, an Ethernet interface 23 required for wired connection with the terminal display module 1, a LoRa module 24, a CPU module 25, and an output module 4 Or the Ethernet interface 26 required for the connection of the input module 5, the CAN interface 27 required for con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com