System for washing and drying wafer

A wafer and drying technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of not reaching a high drying effect, particle residue, and long consumption time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is described in further detail now in conjunction with accompanying drawing.

[0029] Embodiments provided by the present invention relate to the drying of wet wafers in CMP equipment capable of providing flushing gases such as nitrogen (N2) and flushing solutions such as deionized water (Deionized Water, DIW) and isopropanol solvent (IPA)).

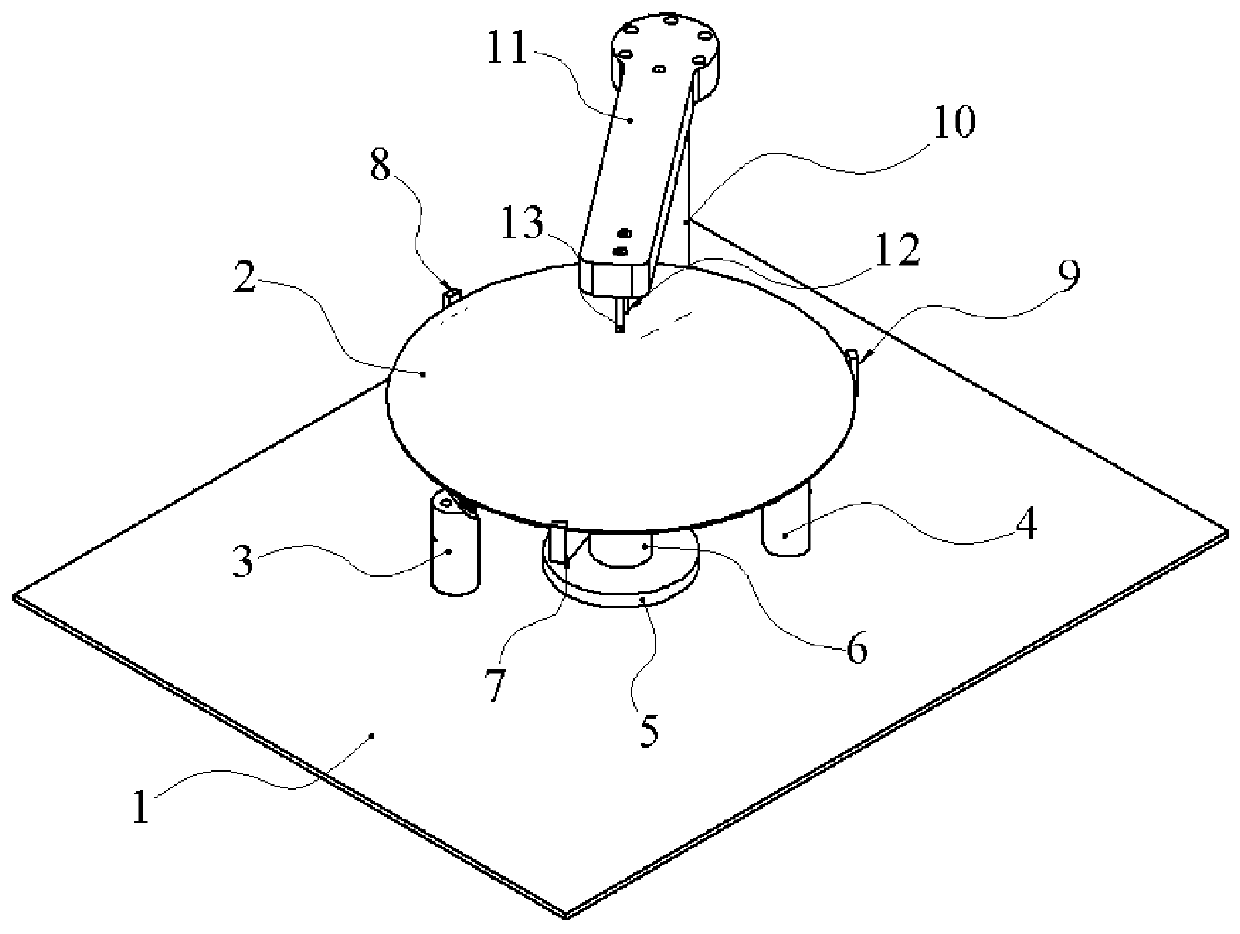

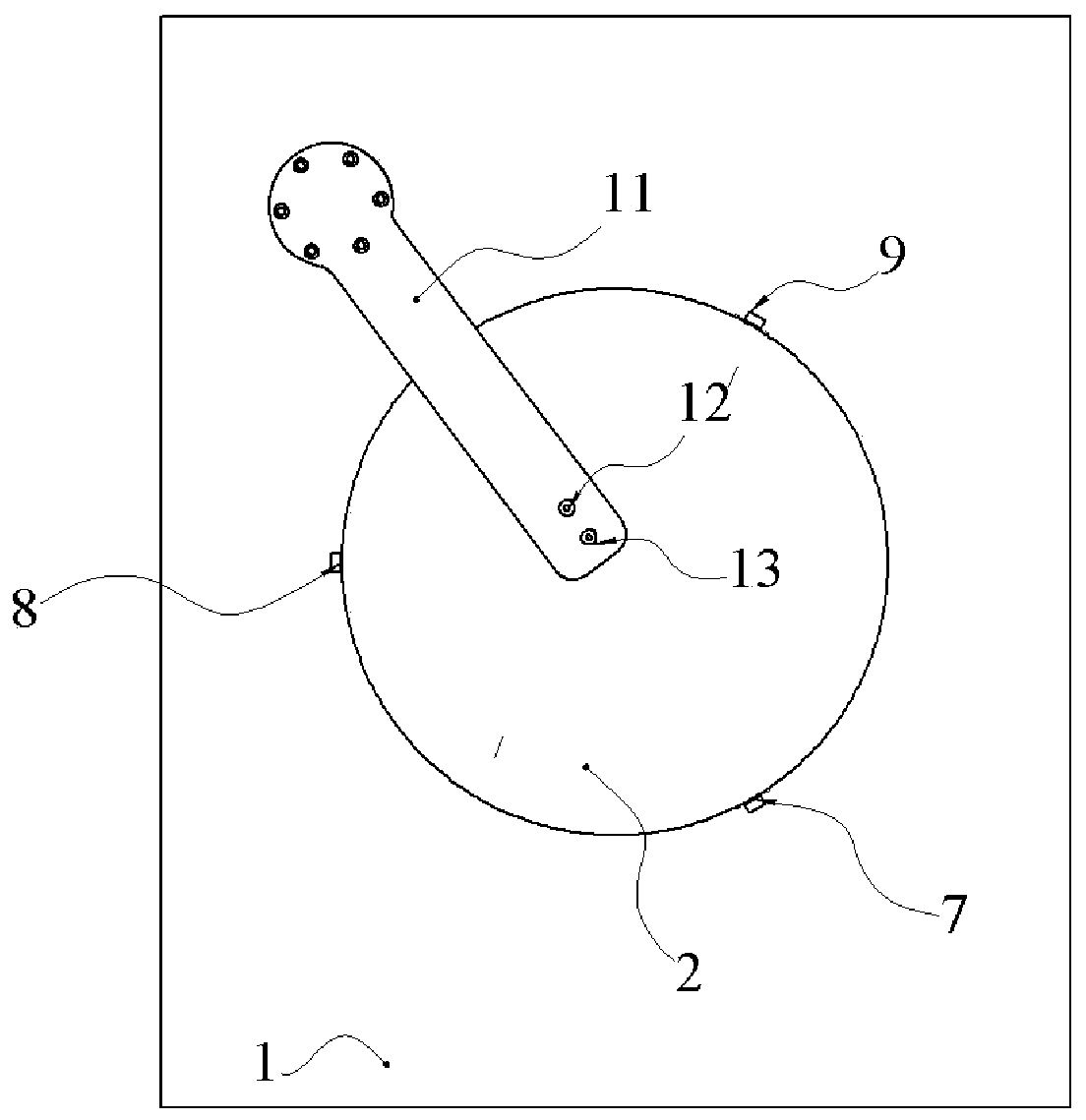

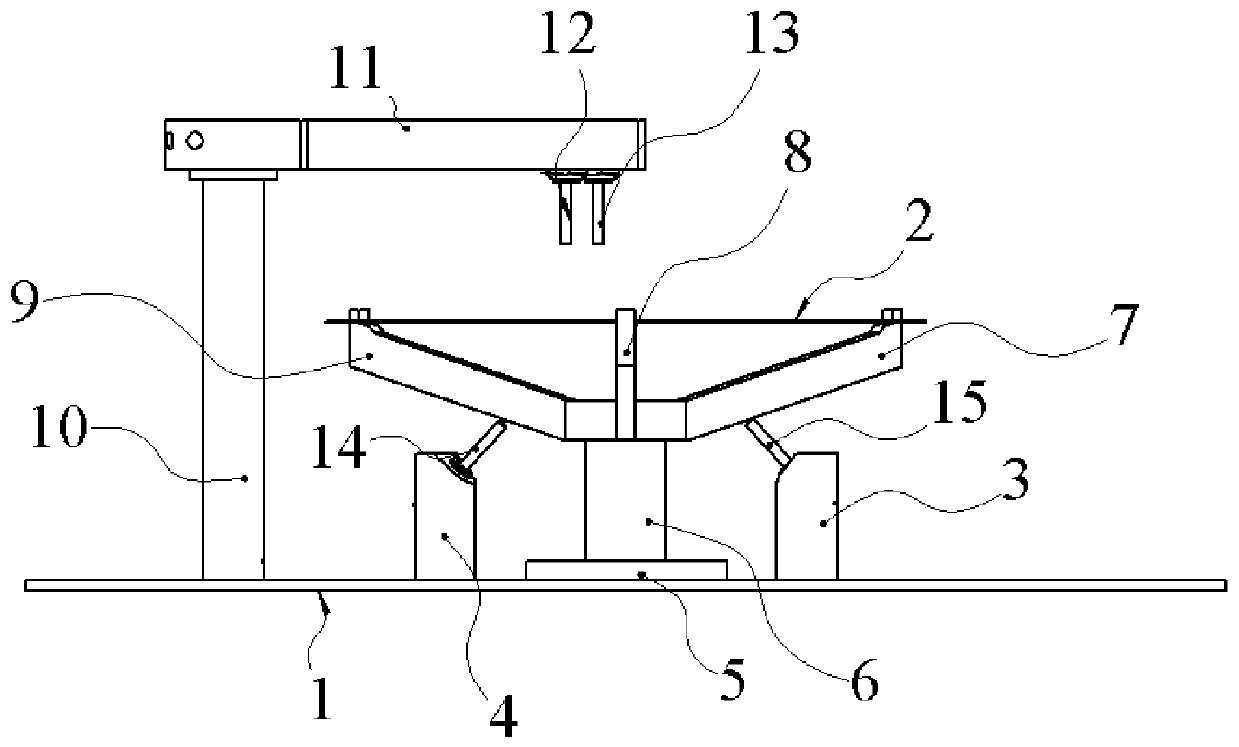

[0030] figure 1 , figure 2 , image 3 Respectively represent an isometric view, a top view and a side view of a washing and drying system according to an embodiment of the present invention. This system can be used in CMP rinse and dry processes where particulates originating from previous steps in the CMP process are removed from the wafer and the entire wet wafer is dried. Removing the solution and particles attached to the solution from the wafer 2 generally improves overall component yield and performance.

[0031] The whole system comprises a bottom fixed plate 1, several spray member mounting part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com