Protective nozzle cap, plasma arc torch comprising said protective nozzle cap, and use of the plasma arc torch

A plasma and protective cover technology, applied in the direction of plasma, electrical components, etc., can solve the problems of degradation of cutting quality, damage of nozzle protective cover, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

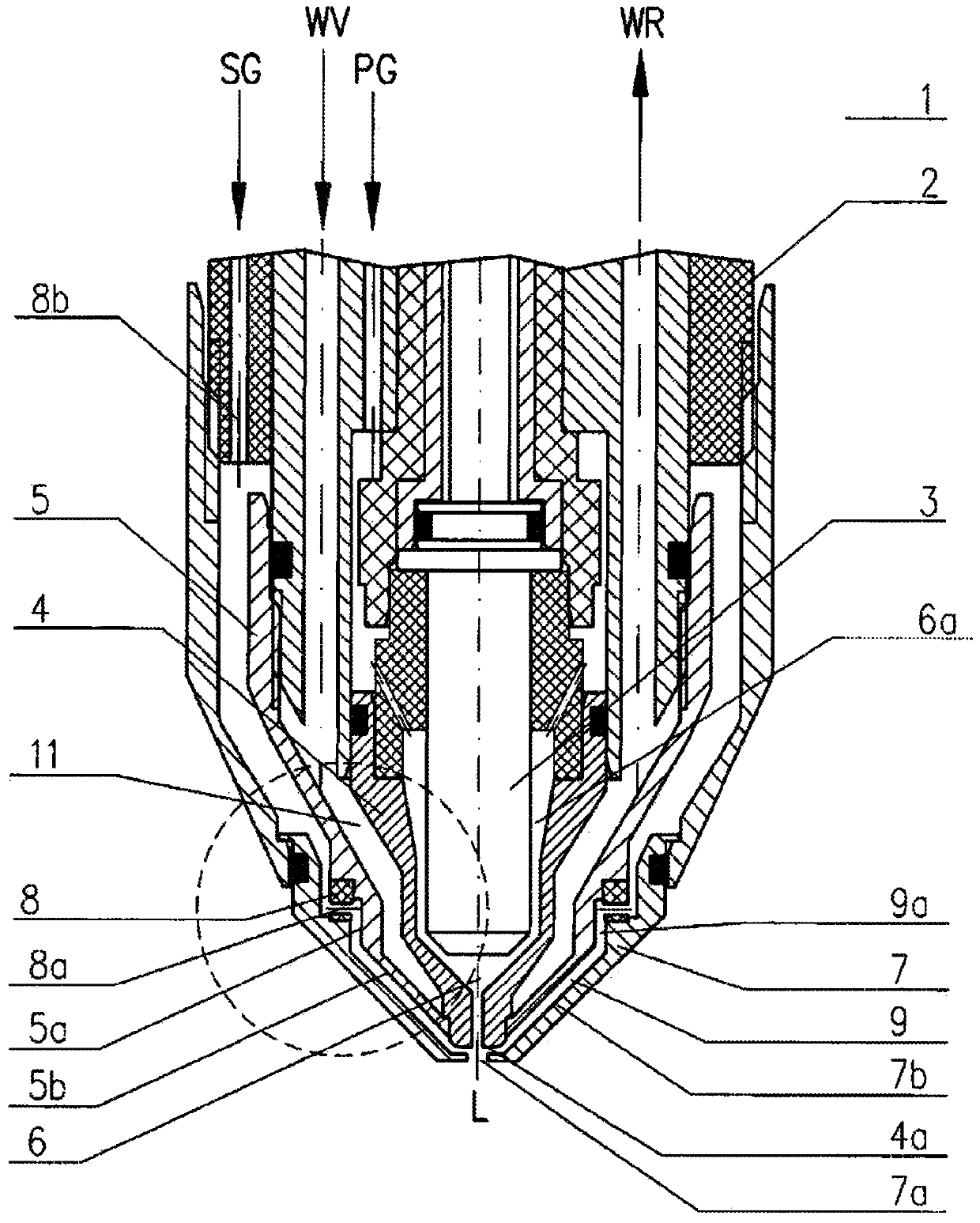

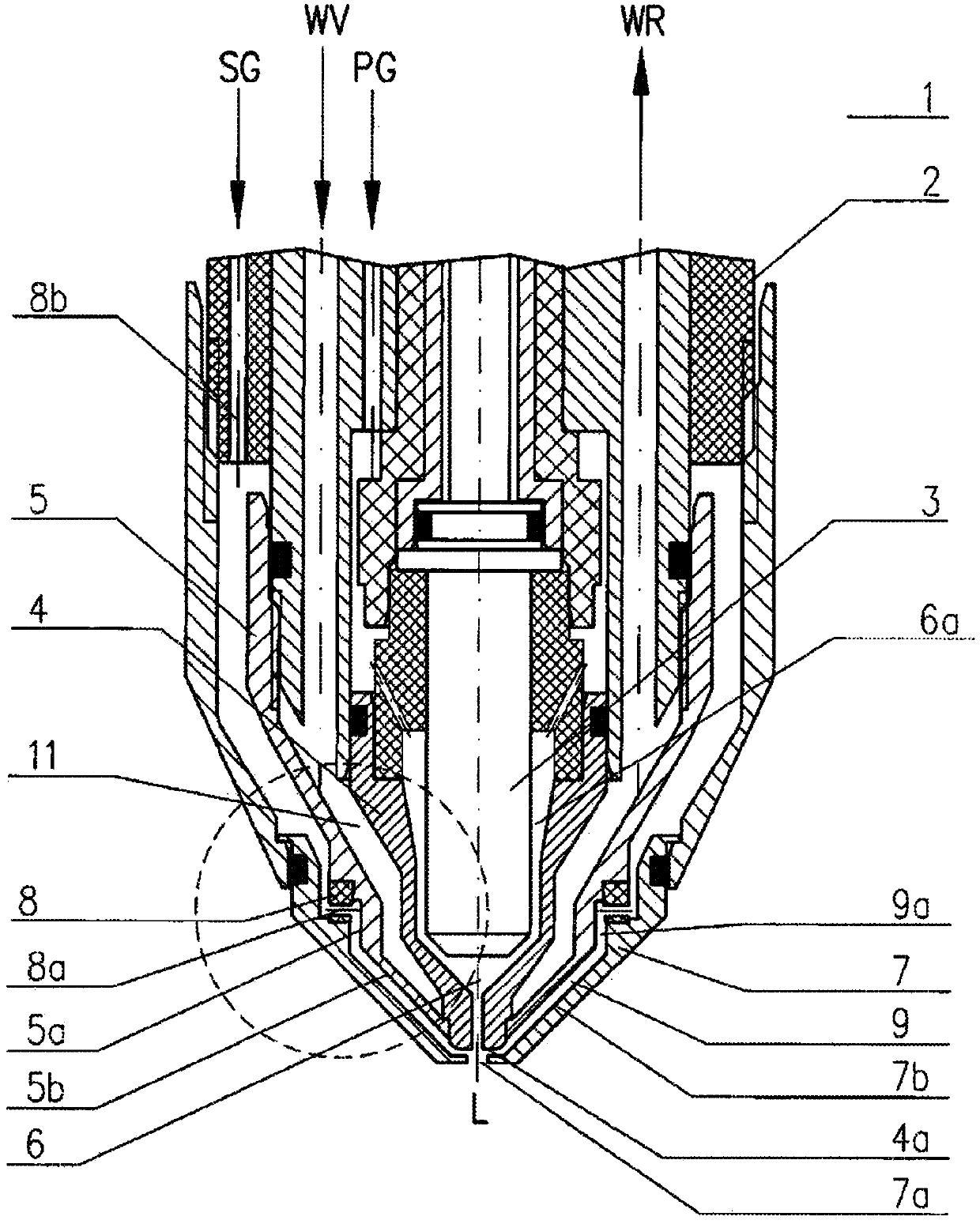

[0033] figure 1 A plasma torch 1 according to a particular embodiment of the invention is shown. The plasma torch 1 has a torch body 2 and an electrode 3 and a nozzle 4 which are substantially rotationally symmetrical about a longitudinal axis L of the plasma torch 1 . The electrode 3 and the nozzle 4 coaxially arranged in the torch body 2 are positioned in a specific spatial relationship and form a plasma chamber 6 through which a plasma gas PG flows, which is supplied through a plasma gas channel 6a. The nozzle cover 5 is arranged coaxially with respect to the longitudinal axis L of the plasma torch 1 and holds and surrounds the nozzle 4 with a protective effect. The cavity 11 through which the cooling water flows is located between the nozzle 4 and the nozzle cover 5 . Cooling water is supplied through the water supply channel WV and flows out through the water return channel WR.

[0034] An annular secondary gas guide portion 8 having a plurality of passages (particular...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com