Scrubber base and scrubber set

A washing machine and kit technology, applied to machine parts, cleaning carpets, cleaning floors, etc., can solve problems such as shortened service life, spring fatigue, edge deformation of the roller brush surface and scraping strip, etc., to solve fatigue and failure, Extend the service life and ensure the effect of cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

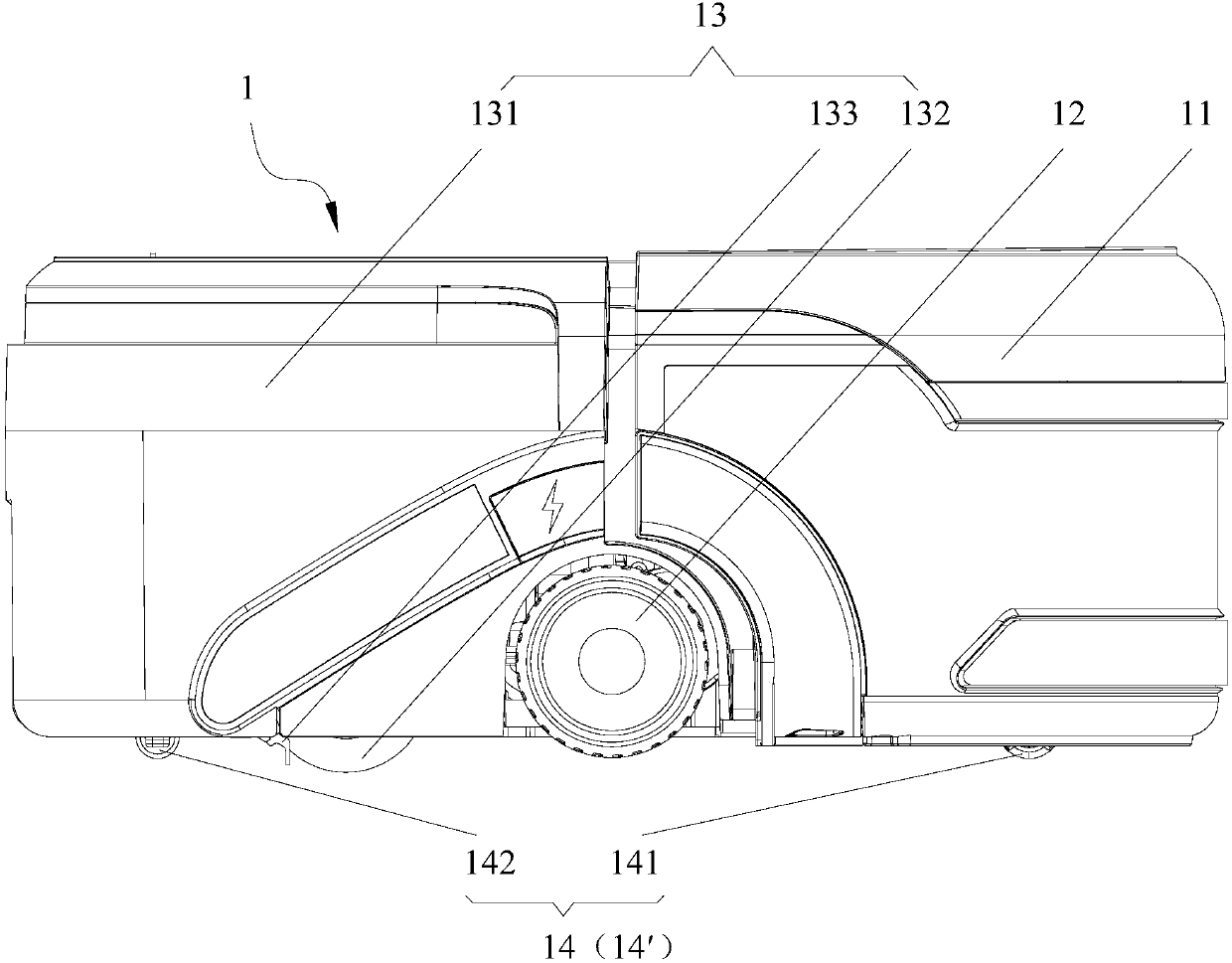

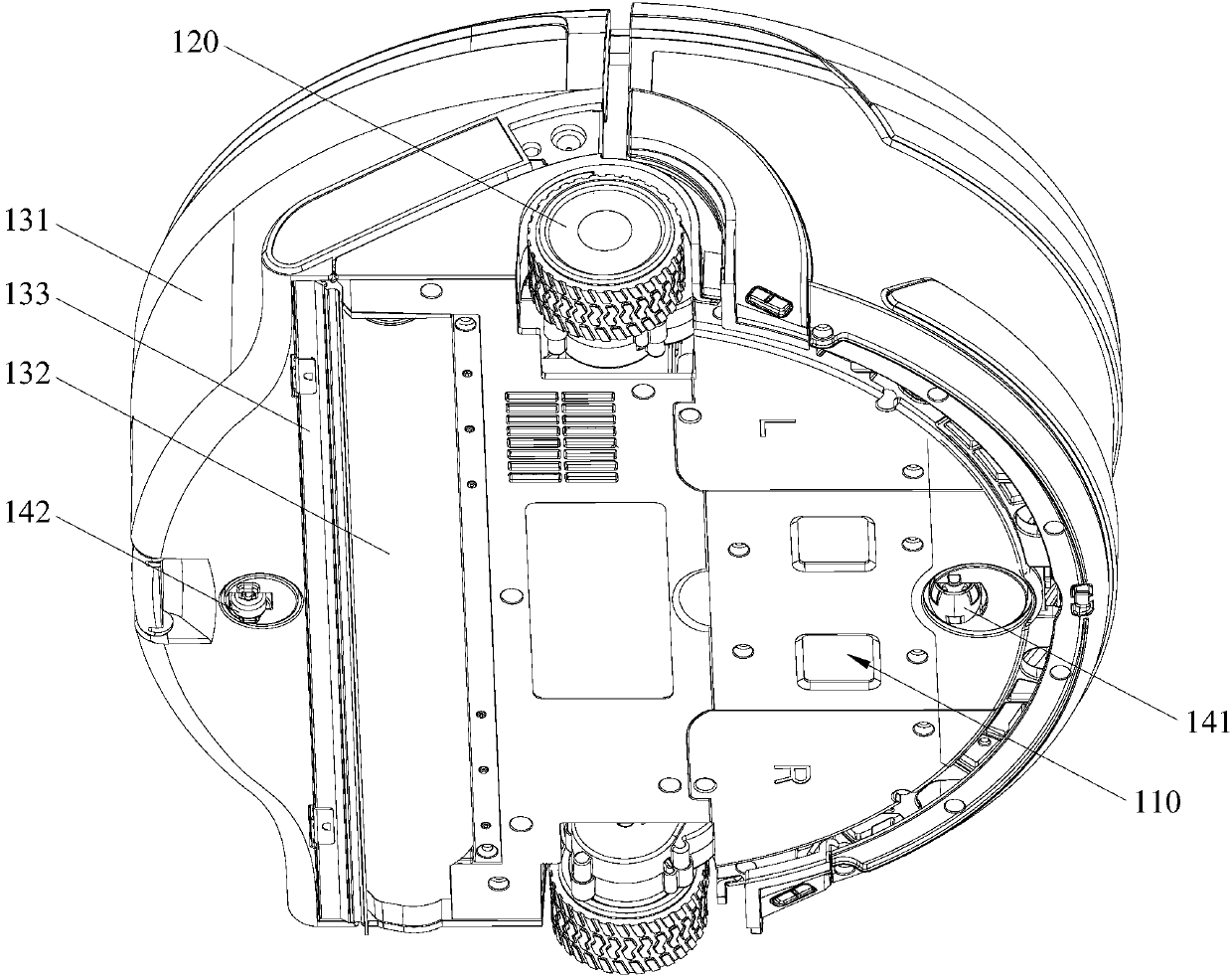

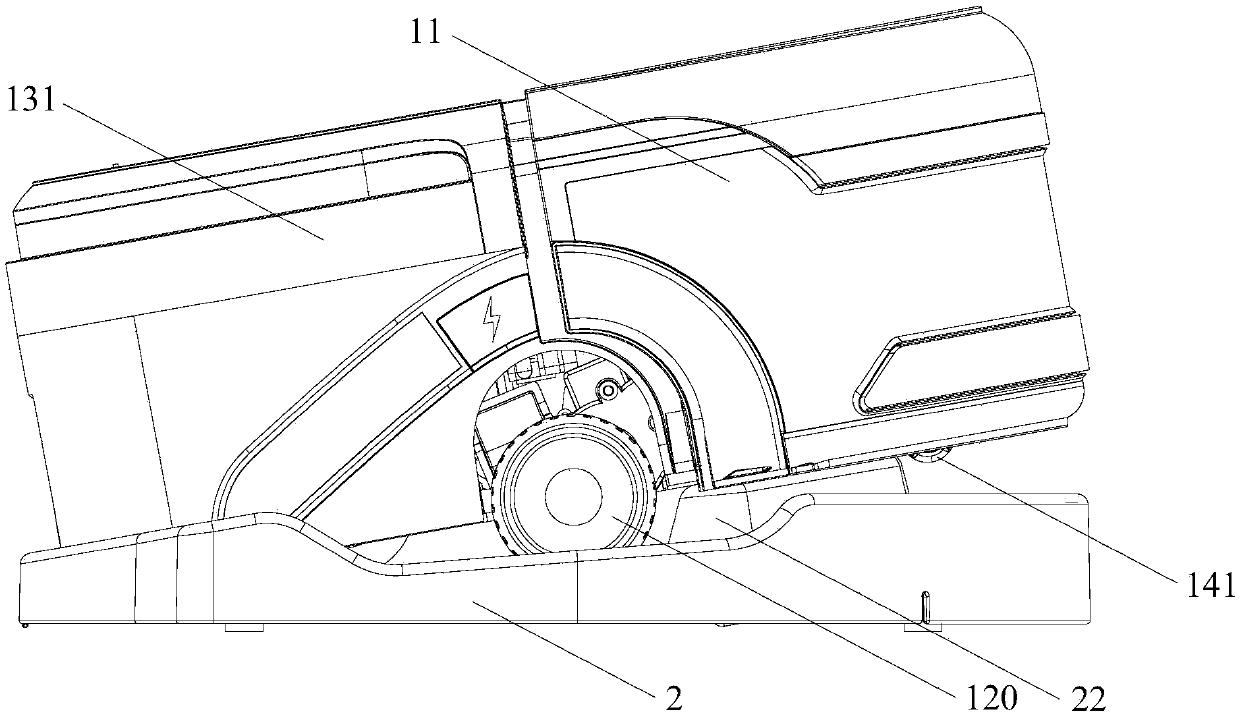

[0043] Further, see Figure 5 with Image 6, as a specific embodiment of the floor washing machine kit provided by the present invention, the above-mentioned cleaning mechanism 13 also includes a water suction port 134 and a sealing assembly, wherein the water suction port 134 is set on the bottom surface of the water tank 131, and the sealing assembly is movably connected with the water tank 131 , here, the seal assembly includes a seal (not shown) and a jack switch 1350, the seal can cover the water suction port 134, the jack switch 1350 is in transmission connection with the seal, and the drive mechanism 12 includes a side wheel set 120, the side wheel set 120 abuts against the push rod switch 1350 to drive the sealing member to cover the water suction port 134 or to open the water suction port 134. Specifically, in the cleaning operation state of the floor washing machine 1, the side wheel set 120 pushes the push rod switch 1350 upward under the reaction force of the grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com