Automatic assembling device for hardware

An automatic assembly and hardware technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of affecting the service life, damage to the pressure head pressing cylinder, damage to the connecting column, etc., to improve work efficiency and ensure good quality. The effect of rate, simple mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

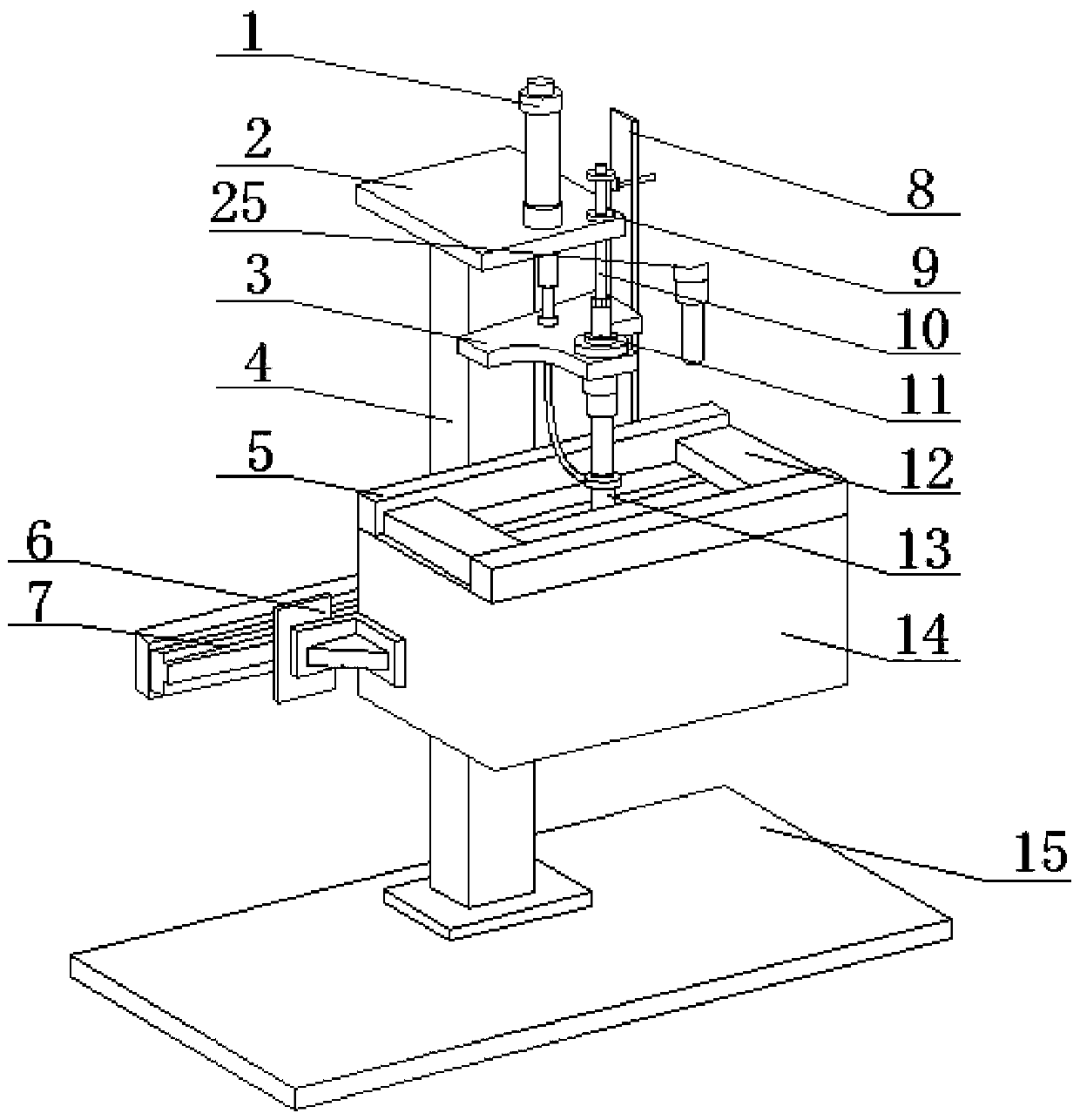

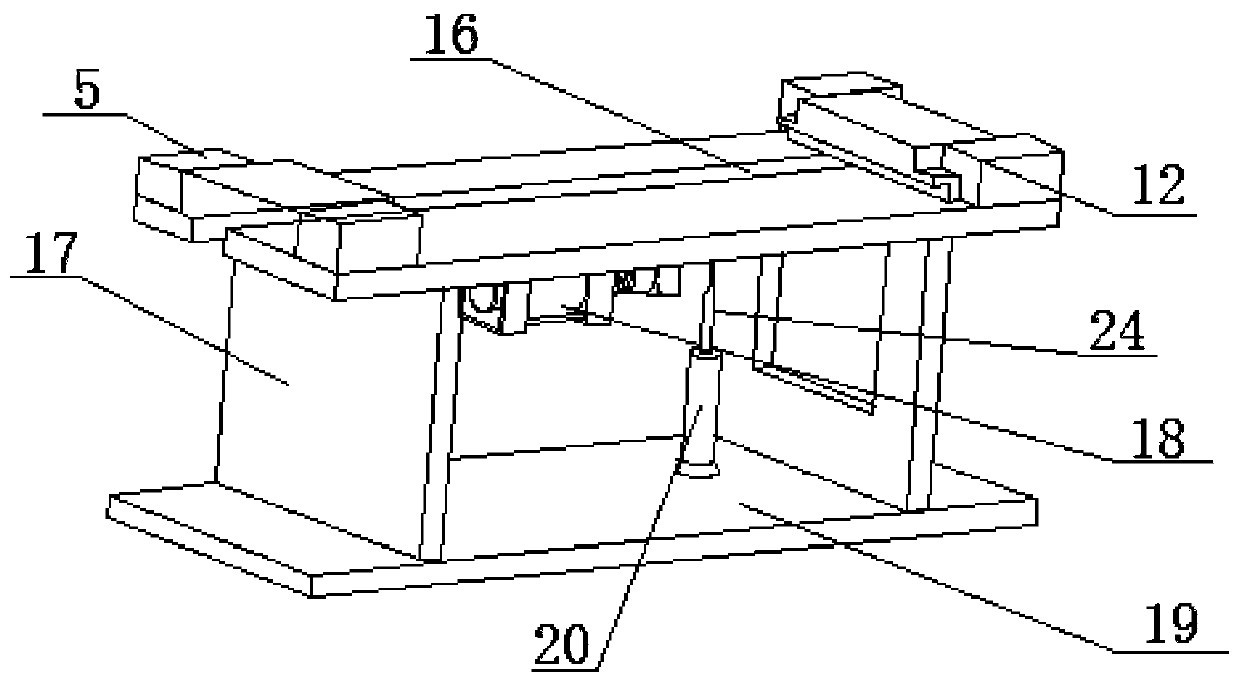

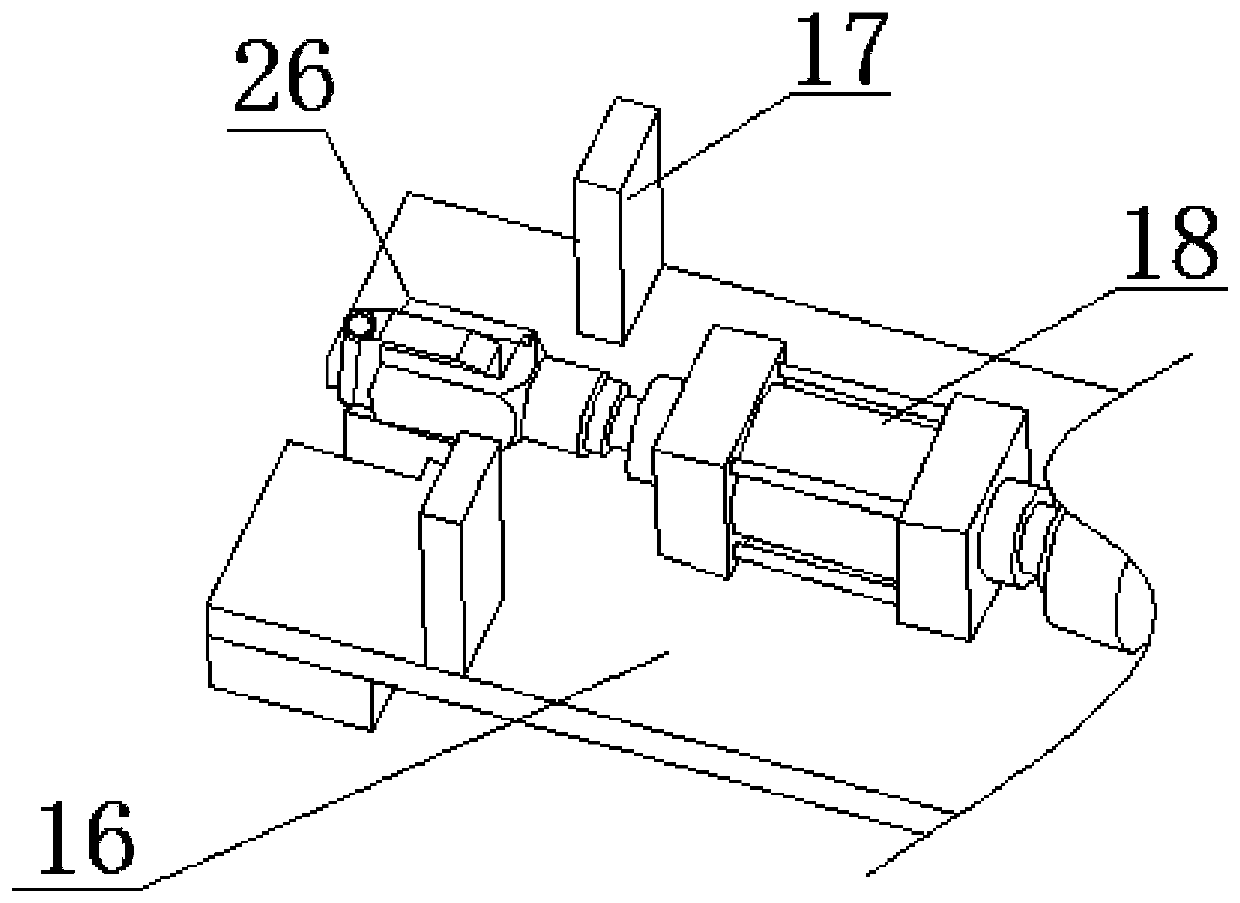

[0032] Reference Figure 1-9 , An automatic hardware assembly device, which is used to connect the hardware, and the hardware includes a connecting piece 21, a connecting piece 22 and a connecting column 23. The assembling device is used to connect the connecting column 23 Piece one and connecting piece two are connected together;

[0033] It includes a connecting column dropping mechanism, an anchoring head 25, an assembly platform 14, a connecting piece locking mechanism, and a connecting piece correcting mechanism. The assembly platform is horizontally movably arranged on the upright 4 on the bottom plate 15. The upright In a vertical arrangement, the connecting column dropping mechanism is provided on the column 4 above the assembly platform, and the connecting column dropping mechanism is responsible for discharging the connecting column; the assembly platform is provided with The connecting piece locking mechanism, the connecting piece locking mechanism is responsible for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com